Основной каталог Kyocera 2016-2017 - страница 688

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

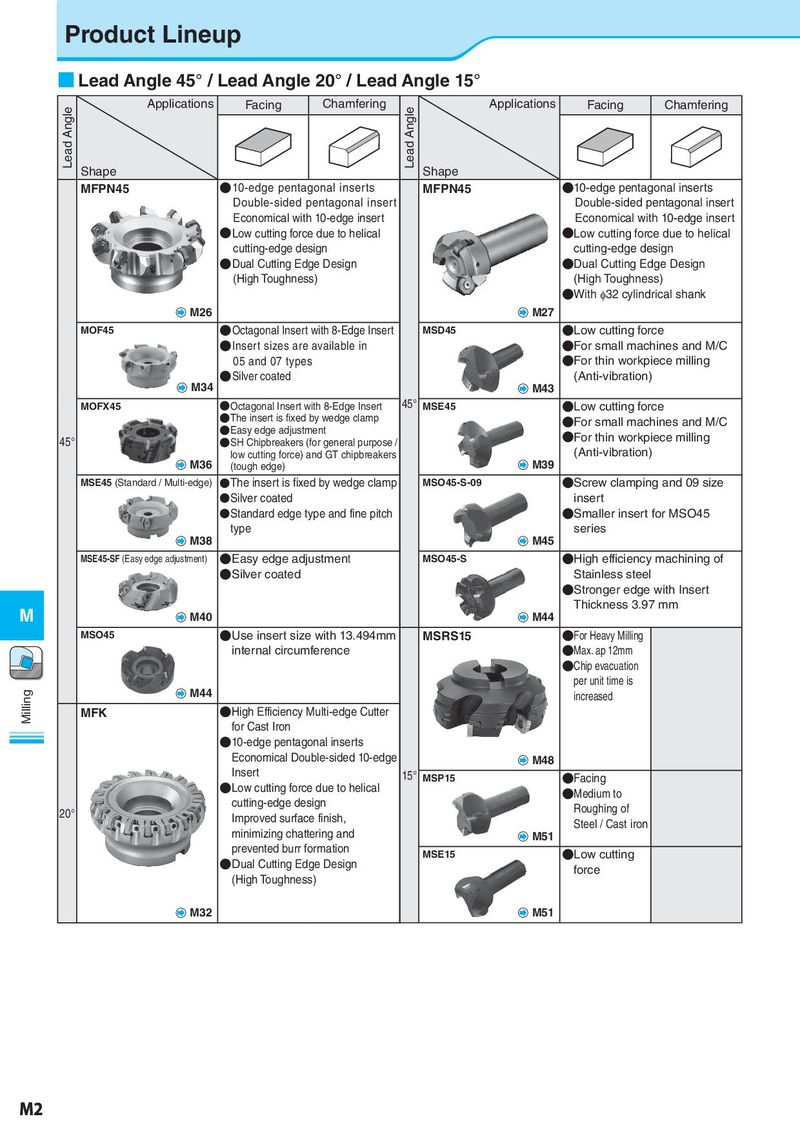

Product Lineup ■ Lead Angle 45° / Lead Angle 20° / Lead Angle 15° Lead Angle Applications Facing Chamfering Lead Angle Applications Facing Chamfering Shape Shape MFPN45 ●10-edge pentagonal inserts MFPN45 ●10-edge pentagonal inserts Double-sided pentagonal insert Double-sided pentagonal insert Economical with 10-edge insert Economical with 10-edge insert ●Low cutting force due to helical ●Low cutting force due to helical cutting-edge design cutting-edge design ●Dual Cutting Edge Design ●Dual Cutting Edge Design (High Toughness) (High Toughness) ●With φ32 cylindrical shank M26 M27 MOF45 ●Octagonal Insert with 8-Edge Insert MSD45 ●Low cutting force ●Insert sizes are available in ●For small machines and M/C 05 and 07 types ●For thin workpiece milling ●Silver coated (Anti-vibration) M34 M43 MOFX45 ●Octagonal Insert with 8-Edge Insert 45° MSE45 ●Low cutting force ●The insert is fixed by wedge clamp ●For small machines and M/C ●Easy edge adjustment ●For thin workpiece milling 45° ●SH Chipbreakers (for general purpose / (Anti-vibration) low cutting force) and GT chipbreakers M36 (tough edge) M39 MSE45 (Standard / Multi-edge) ●The insert is fixed by wedge clamp MSO45-S-09 ●Screw clamping and 09 size ●Silver coated insert ●Standard edge type and fine pitch ●Smaller insert for MSO45 type series M38 M45 MSE45-SF (Easy edge adjustment) ●Easy edge adjustment MSO45-S ●High efficiency machining of ●Silver coated Stainless steel ●Stronger edge with Insert M Thickness 3.97 mm M40 M44 MSO45 ●Use insert size with 13.494mm MSRS15 ●For Heavy Milling internal circumference ●Max. ap 12mm ●Chip evacuation per unit time is Milling M44 increased MFK ●High Efficiency Multi-edge Cutter for Cast Iron ●10-edge pentagonal inserts Economical Double-sided 10-edge M48 Insert 15° MSP15 ●Facing ●Low cutting force due to helical ●Medium to 20° cutting-edge design Roughing of Improved surface finish, Steel / Cast iron minimizing chattering and M51 prevented burr formation MSE15 ●Low cutting ●Dual Cutting Edge Design force (High Toughness) M32 M51 M2