Основной каталог Kyocera 2016-2017 - страница 682

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

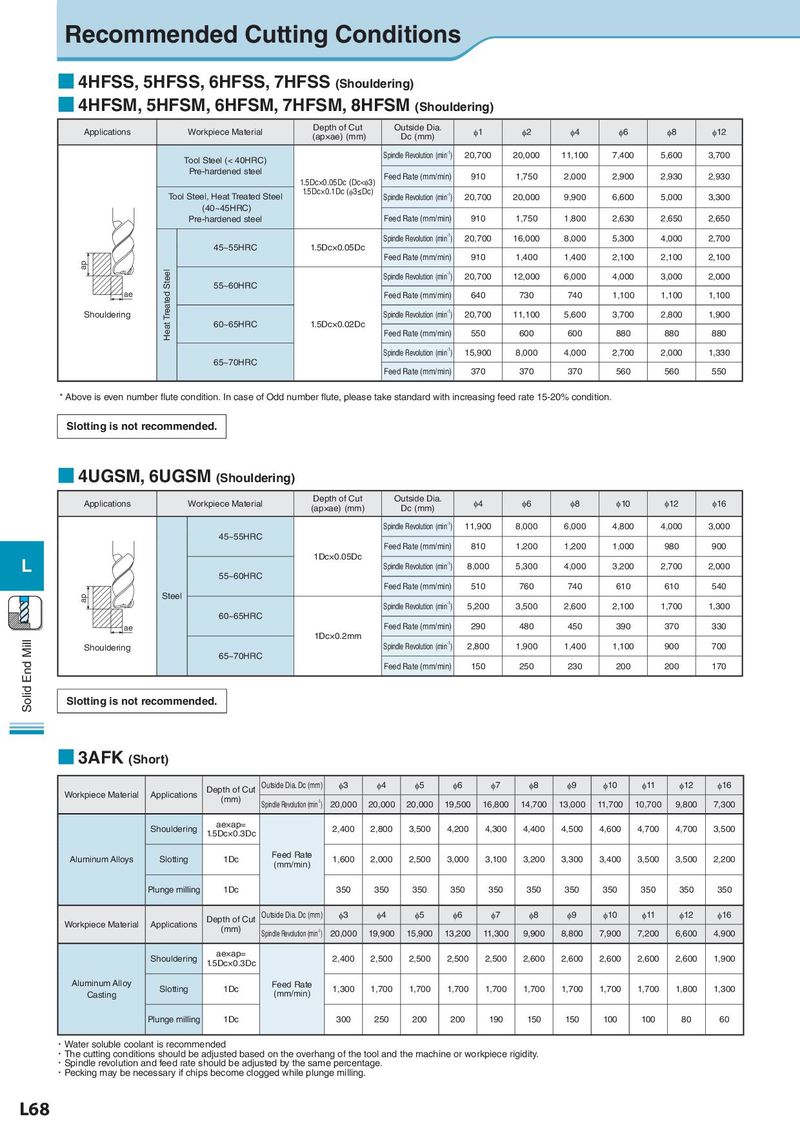

Recommended Cutting Conditions ■ 4HFSS, 5HFSS, 6HFSS, 7HFSS (Shouldering) ■ 4HFSM, 5HFSM, 6HFSM, 7HFSM, 8HFSM (Shouldering) Applications Workpiece Material Depth of Cut Outside Dia. φ1 φ2 φ4 φ6 φ8 φ12 (ap×ae) (mm) Dc (mm) Tool Steel (< 40HRC) Spindle Revolution (min-1) 20,700 20,000 11,100 7,400 5,600 3,700 Pre-hardened steel Feed Rate (mm/min) 910 1,750 2,000 2,900 2,930 2,930 1.5Dc×0.05Dc (Dc<φ3) Tool Steel, Heat Treated Steel 1.5Dc×0.1Dc (φ3≤Dc) Spindle Revolution (min-1) 20,700 20,000 9,900 6,600 5,000 3,300 (40~45HRC) Pre-hardened steel Feed Rate (mm/min) 910 1,750 1,800 2,630 2,650 2,650 Spindle Revolution (min-1) 20,700 16,000 8,000 5,300 4,000 2,700 45~55HRC 1.5Dc×0.05Dc ap Feed Rate (mm/min) 910 1,400 1,400 2,100 2,100 2,100 Heat Treated Steel Spindle Revolution (min-1) 20,700 12,000 6,000 4,000 3,000 2,000 55~60HRC ae Feed Rate (mm/min) 640 730 740 1,100 1,100 1,100 Shouldering Spindle Revolution (min-1) 20,700 11,100 5,600 3,700 2,800 1,900 60~65HRC 1.5Dc×0.02Dc Feed Rate (mm/min) 550 600 600 880 880 880 Spindle Revolution (min-1) 15,900 8,000 4,000 2,700 2,000 1,330 65~70HRC Feed Rate (mm/min) 370 370 370 560 560 550 * Above is even number flute condition. In case of Odd number flute, please take standard with increasing feed rate 15-20% condition. Slotting is not recommended. ■ 4UGSM, 6UGSM (Shouldering) Applications Workpiece Material Depth of Cut Outside Dia. φ4 φ6 φ8 φ10 φ12 φ16 (ap×ae) (mm) Dc (mm) Spindle Revolution (min-1) 11,900 8,000 6,000 4,800 4,000 3,000 45~55HRC Feed Rate (mm/min) 810 1,200 1,200 1,000 980 900 L 1Dc×0.05Dc Spindle Revolution (min-1) 8,000 5,300 4,000 3,200 2,700 2,000 55~60HRC Feed Rate (mm/min) 510 760 740 610 610 540 ap Steel Spindle Revolution (min-1) 5,200 3,500 2,600 2,100 1,700 1,300 60~65HRC ae Feed Rate (mm/min) 290 480 450 390 370 330 Solid End Mill 1Dc×0.2mm Shouldering Spindle Revolution (min-1) 2,800 1,900 1,400 1,100 900 700 65~70HRC Feed Rate (mm/min) 150 250 230 200 200 170 Slotting is not recommended. ■ 3AFK (Short) Depth of Cut Outside Dia. Dc (mm) φ3 φ4 φ5 φ6 φ7 φ8 φ9 φ10 φ11 φ12 φ16 Workpiece Material Applications (mm) Spindle Revolution (min-1) 20,000 20,000 20,000 19,500 16,800 14,700 13,000 11,700 10,700 9,800 7,300 Shouldering ae×ap= 2,400 2,800 3,500 4,200 4,300 4,400 4,500 4,600 4,700 4,700 3,500 1.5Dc×0.3Dc Aluminum Alloys Slotting 1Dc Feed Rate 1,600 2,000 2,500 3,000 3,100 3,200 3,300 3,400 3,500 3,500 2,200 (mm/min) Plunge milling 1Dc 350 350 350 350 350 350 350 350 350 350 350 Depth of Cut Outside Dia. Dc (mm) φ3 φ4 φ5 φ6 φ7 φ8 φ9 φ10 φ11 φ12 φ16 Workpiece Material Applications (mm) Spindle Revolution (min-1) 20,000 19,900 15,900 13,200 11,300 9,900 8,800 7,900 7,200 6,600 4,900 Shouldering ae×ap= 2,400 2,500 2,500 2,500 2,500 2,600 2,600 2,600 2,600 2,600 1,900 1.5Dc×0.3Dc Aluminum Alloy Slotting 1Dc Feed Rate 1,300 1,700 1,700 1,700 1,700 1,700 1,700 1,700 1,700 1,800 1,300 Casting (mm/min) Plunge milling 1Dc 300 250 200 200 190 150 150 100 100 80 60 ・Water soluble coolant is recommended ・The cutting conditions should be adjusted based on the overhang of the tool and the machine or workpiece rigidity. ・Spindle revolution and feed rate should be adjusted by the same percentage. ・Pecking may be necessary if chips become clogged while plunge milling. L68