Основной каталог Kyocera 2016-2017 - страница 650

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

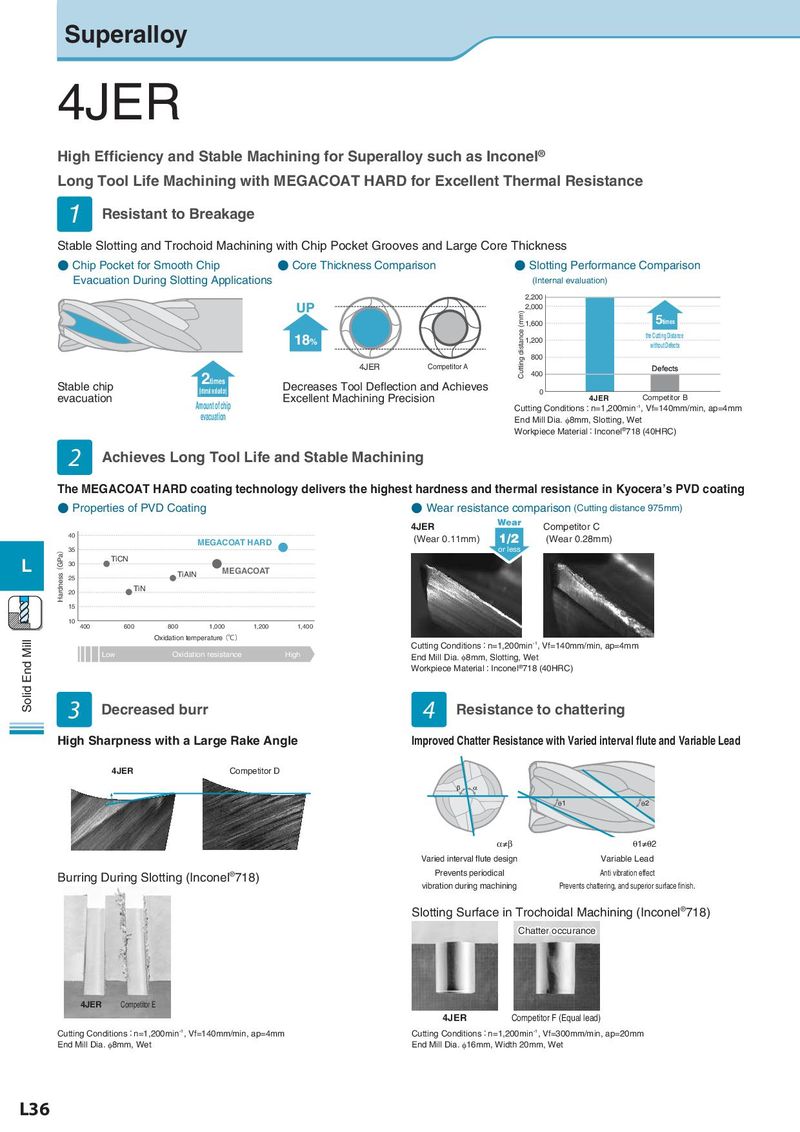

Superalloy 4JER High Efficiency and Stable Machining for Superalloy such as Inconel® Long Tool Life Machining with MEGACOAT HARD for Excellent Thermal Resistance 1 Resistant to Breakage 2times Stable Slotting and Trochoid Machining (Internal evaluation) witAhmouCnt ofhchiipp Pocket Grooves and Large Core Thickness ● Chip Pocket for Smooth Chip ● Cevaocurateion Thickness Comparison ● Slotting Performance Comparison Evacuation During Slotting Applications (Internal evaluation) 2,200 UP 2,000 Cutting distance (mm) 1,600 5times 18% 1,200 the Cutting Distance without Defects 800 4JER Competitor A Defects 2times 400 Stable chip (Internal evaluation) Decreases Tool Deflection and Achieves 0 evacuation Excellent Machining Precision 4JER Competitor B Amount of chip Cutting Conditions:n=1,200min-1, Vf=140mm/min, ap=4mm evacuation End Mill Dia. φ8mm, Slotting, Wet Workpiece Material:Inconel®718 (40HRC) 2 Achieves LongUTPool Life and Stable Machining The MEGACOAT HARD co1a8ti%ng technology delivers the highest hardness and thermal resistance in Kyocera’s PVD coating ● Properties of PVD Coating ● Wear resistance comparison (Cutting distance 975mm) 4JER Wear Competitor C 40 (Wear 0.11mm) 1/2 (Wear 0.28mm) Hardness(GPa) MEGACOAT HARD or less 35 L 30 TiCN TiAIN MEGACOAT 25 20 TiN 15 10 400 600 800 1,000 1,200 1,400 Solid End Mill Oxidation temperature(℃) Cutting Conditions:n=1,200min-1, Vf=140mm/min, ap=4mm Low Oxidation resistance High End Mill Dia. φ8mm, Slotting, Wet Workpiece Material:Inconel®718 (40HRC) 3 Decreased burr 4 Resistance to chattering High Sharpness with a Large Rake Angle Improved Chatter Resistance with Varied interval flute and Variable Lead 4JER Competitor D β α θ1 θ2 α≠β θ1≠θ2 Varied interval flute design Variable Lead Burring During Slotting (Inconel®718) Prevents periodical Anti vibration effect vibration during machining Prevents chattering, and superior surface finish. Slotting Surface in Trochoidal Machining (Inconel®718) Chatter occurance 4JER Competitor E 4JER Competitor F (Equal lead) Cutting Conditions:n=1,200min-1, Vf=140mm/min, ap=4mm Cutting Conditions:n=1,200min-1, Vf=300mm/min, ap=20mm End Mill Dia. φ8mm, Wet End Mill Dia. φ16mm, Width 20mm, Wet L36