Основной каталог Kyocera 2016-2017 - страница 651

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

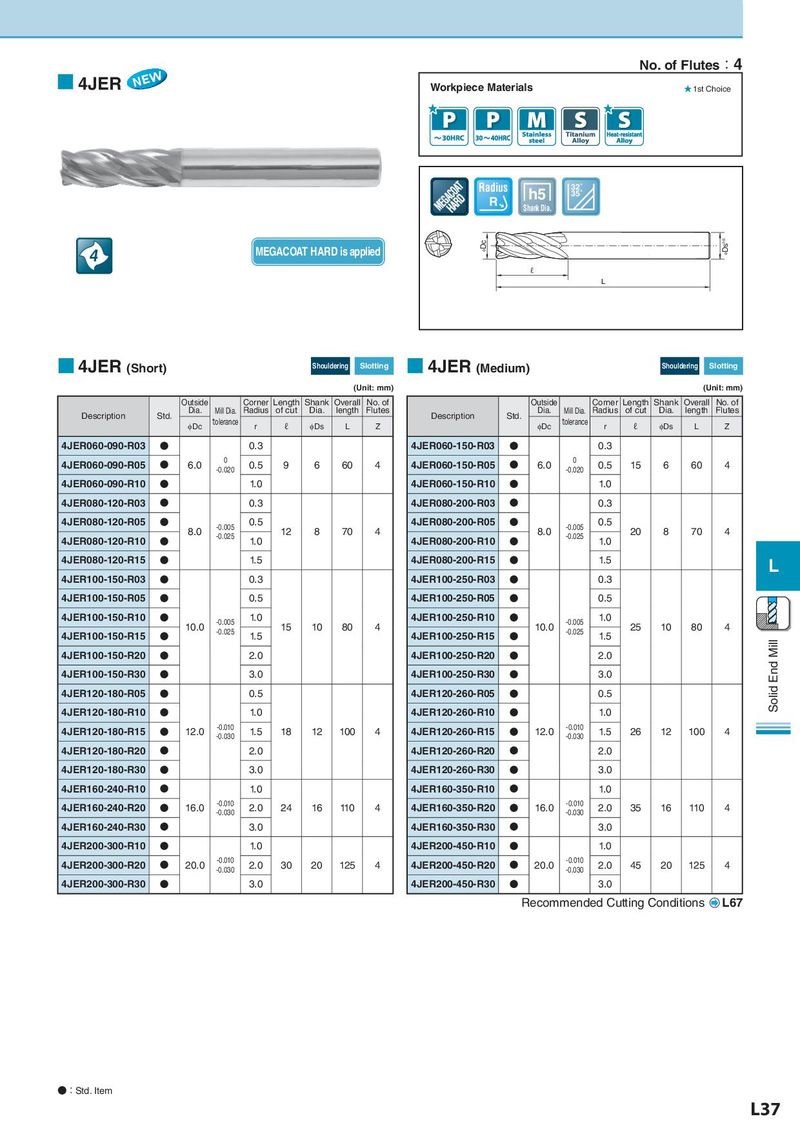

No. of Flutes:4 ■ 4JER 1(: Workpiece Materials ★ 1st Choice Radius h5 32˚ 35˚ R Shank Dia. 4 MEGACOAT HARD is applied φDc φDsh5 ℓ L ■ 4JER (Short) Shouldering Slotting ■ 4JER (Medium) Shouldering Slotting (Unit: mm) (Unit: mm) Outside Corner Length Shank Overall No. of Outside Corner Length Shank Overall No. of Dia. Radius of cut Dia. length Flutes Dia. Radius of cut Dia. length Flutes Description Std. Mill Dia. Description Std. Mill Dia. φDc tolerance r ℓ φDs L Z φDc tolerance r ℓ φDs L Z 4JER060-090-R03 N 0.3 4JER060-150-R03 N 0.3 4JER060-090-R05 N 6.0 0 0.5 9 6 60 4 4JER060-150-R05 N 6.0 0 0.5 15 6 60 4 -0.020 -0.020 4JER060-090-R10 N 1.0 4JER060-150-R10 N 1.0 4JER080-120-R03 N 0.3 4JER080-200-R03 N 0.3 4JER080-120-R05 N -0.005 0.5 4JER080-200-R05 N -0.005 0.5 8.0 -0.025 12 8 70 4 8.0 -0.025 20 8 70 4 4JER080-120-R10 N 1.0 4JER080-200-R10 N 1.0 4JER080-120-R15 N 1.5 4JER080-200-R15 N 1.5 L 4JER100-150-R03 N 0.3 4JER100-250-R03 N 0.3 4JER100-150-R05 N 0.5 4JER100-250-R05 N 0.5 4JER100-150-R10 N -0.005 1.0 4JER100-250-R10 N -0.005 1.0 10.0 -0.025 15 10 80 4 10.0 -0.025 25 10 80 4 4JER100-150-R15 N 1.5 4JER100-250-R15 N 1.5 Solid End Mill 4JER100-150-R20 N 2.0 4JER100-250-R20 N 2.0 4JER100-150-R30 N 3.0 4JER100-250-R30 N 3.0 4JER120-180-R05 N 0.5 4JER120-260-R05 N 0.5 4JER120-180-R10 N 1.0 4JER120-260-R10 N 1.0 4JER120-180-R15 N 12.0 -0.010 1.5 18 12 100 4 4JER120-260-R15 N 12.0 -0.010 1.5 26 12 100 4 -0.030 -0.030 4JER120-180-R20 N 2.0 4JER120-260-R20 N 2.0 4JER120-180-R30 N 3.0 4JER120-260-R30 N 3.0 4JER160-240-R10 N 1.0 4JER160-350-R10 N 1.0 4JER160-240-R20 N 16.0 -0.010 2.0 24 16 110 4 4JER160-350-R20 N 16.0 -0.010 2.0 35 16 110 4 -0.030 -0.030 4JER160-240-R30 N 3.0 4JER160-350-R30 N 3.0 4JER200-300-R10 N 1.0 4JER200-450-R10 N 1.0 4JER200-300-R20 N 20.0 -0.010 2.0 30 20 125 4 4JER200-450-R20 N 20.0 -0.010 2.0 45 20 125 4 -0.030 -0.030 4JER200-300-R30 N 3.0 4JER200-450-R30 N 3.0 Recommended Cutting Conditions L67 ●:Std. Item L37