Основной каталог Kyocera 2016-2017 - страница 643

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

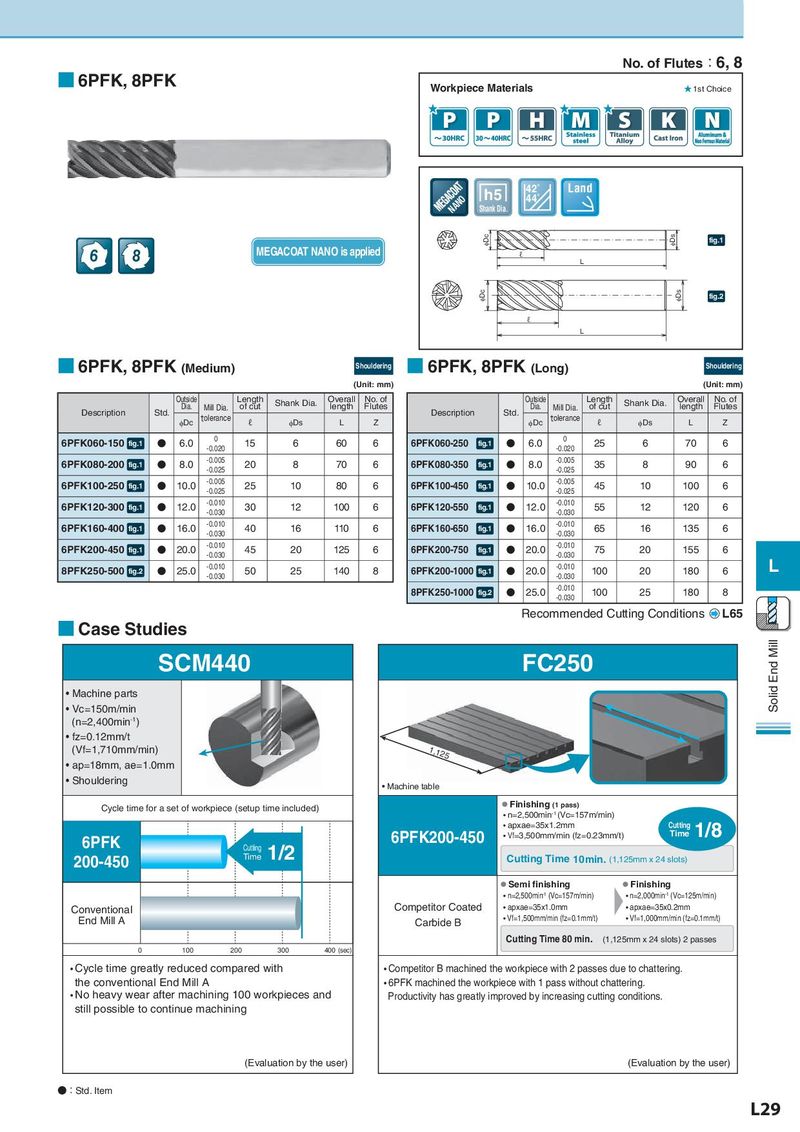

No. of Flutes:6, 8 ■ 6PFK, 8PFK Workpiece Materials ★ 1st Choice h5 42˚ Land 44˚ NANO Shank Dia. φDc φDs fig.1 6 8 MEGACOAT NANO is applied ℓ L φDc φDs fig.2 ℓ L ■ 6PFK, 8PFK (Medium) Shouldering ■ 6PFK, 8PFK (Long) Shouldering (Unit: mm) (Unit: mm) Outside Length Shank Dia. Overall No. of Outside Length Shank Dia. Overall No. of Dia. of cut length Flutes Dia. of cut length Flutes Description Std. Mill Dia. Description Std. Mill Dia. φDc tolerance ℓ φDs L Z φDc tolerance ℓ φDs L Z 6PFK060-150 fig.1 N 6.0 0 15 6 60 6 6PFK060-250 fig.1 N 6.0 0 25 6 70 6 -0.020 -0.020 6PFK080-200 fig.1 N 8.0 -0.005 20 8 70 6 6PFK080-350 fig.1 N 8.0 -0.005 35 8 90 6 -0.025 -0.025 6PFK100-250 fig.1 N 10.0 -0.005 25 10 80 6 6PFK100-450 fig.1 N 10.0 -0.005 45 10 100 6 -0.025 -0.025 6PFK120-300 fig.1 N 12.0 -0.010 30 12 100 6 6PFK120-550 fig.1 N 12.0 -0.010 55 12 120 6 -0.030 -0.030 6PFK160-400 fig.1 N 16.0 -0.010 40 16 110 6 6PFK160-650 fig.1 N 16.0 -0.010 65 16 135 6 -0.030 -0.030 6PFK200-450 fig.1 N 20.0 -0.010 45 20 125 6 6PFK200-750 fig.1 N 20.0 -0.010 75 20 155 6 -0.030 -0.030 8PFK250-500 fig.2 N 25.0 -0.010 50 25 140 8 6PFK200-1000 fig.1 N 20.0 -0.010 100 20 180 6 L -0.030 -0.030 8PFK250-1000 fig.2 N 25.0 -0.010 100 25 180 8 -0.030 Recommended Cutting Conditions L65 ■ Case Studies SCM440 FC250 Solid End Mill • Machine parts • Vc=150m/min (n=2,400min-1) • fz=0.12mm/t (Vf=1,710mm/min) 1,125 • ap=18mm, ae=1.0mm • Shouldering • Machine table Cycle time for a set of workpiece (setup time included) ● Finishing (1 pass) • n=2,500min-1 (Vc=157m/min) • apxae=35x1.2mm Cutting 1/8 6PFK 6PFK200-450 • Vf=3,500mm/min (fz=0.23mm/t) Time Cutting 1/2 200-450 Time Cutting Time 10min. (1,125mm x 24 slots) ● Semi finishing ● Finishing • n=2,500min-1 (Vc=157m/min) • n=2,000min-1 (Vc=125m/min) Conventional Competitor Coated • apxae=35x1.0mm • apxae=35x0.2mm End Mill A Carbide B • Vf=1,500mm/min (fz=0.1mm/t) • Vf=1,000mm/min (fz=0.1mm/t) Cutting Time 80 min. (1,125mm x 24 slots) 2 passes 0 100 200 300 400 (sec) • Cycle time greatly reduced compared with • Competitor B machined the workpiece with 2 passes due to chattering. the conventional End Mill A • 6PFK machined the workpiece with 1 pass without chattering. • No heavy wear after machining 100 workpieces and Productivity has greatly improved by increasing cutting conditions. still possible to continue machining (Evaluation by the user) (Evaluation by the user) ●:Std. Item L29