Основной каталог Kyocera 2016-2017 - страница 642

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

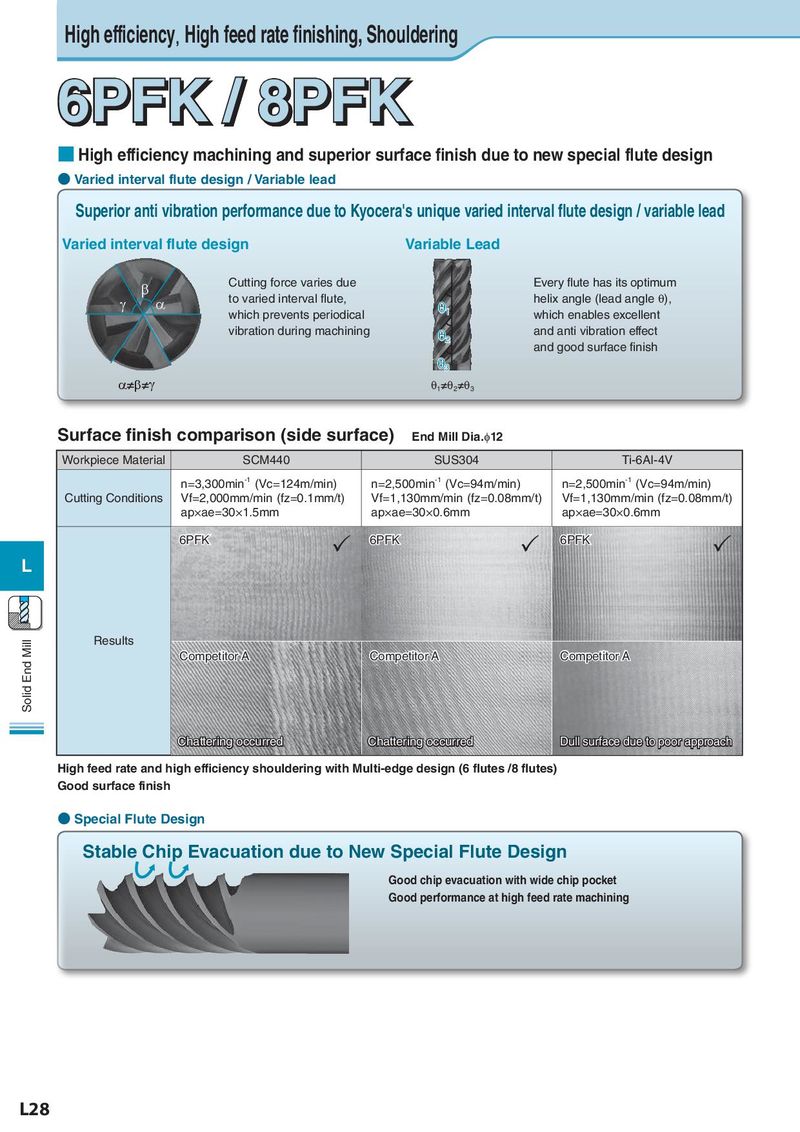

High efficiency, High feed rate finishing, Shouldering 6PFK / 8PFK ■ High efficiency machining and superior surface finish due to new special flute design ● Varied interval flute design / Variable lead Superior anti vibration performance due to Kyocera's unique varied interval flute design / variable lead Varied interval flute design Variable Lead β Cutting force varies due Every flute has its optimum γ α to varied interval flute, θ1 helix angle (lead angle θ), which prevents periodical which enables excellent vibration during machining θ2 and anti vibration effect and good surface finish θ3 α≠β≠γ θ1≠θ2≠θ3 Surface finish comparison (side surface) End Mill Dia.φ12 Workpiece Material SCM440 SUS304 Ti-6AI-4V n=3,300min-1 (Vc=124m/min) n=2,500min-1 (Vc=94m/min) n=2,500min-1 (Vc=94m/min) Cutting Conditions Vf=2,000mm/min (fz=0.1mm/t) Vf=1,130mm/min (fz=0.08mm/t) Vf=1,130mm/min (fz=0.08mm/t) ap×ae=30×1.5mm ap×ae=30×0.6mm ap×ae=30×0.6mm 6PFK P 6PFK P 6PFK P L Solid End Mill Results Competitor A Competitor A Competitor A Chattering occurred Chattering occurred Dull surface due to poor approach High feed rate and high efficiency shouldering with Multi-edge design (6 flutes /8 flutes) Good surface finish ● Special Flute Design Stable Chip Evacuation due to New Special Flute Design Good chip evacuation with wide chip pocket Good performance at high feed rate machining L28