Основной каталог Kyocera 2016-2017 - страница 644

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

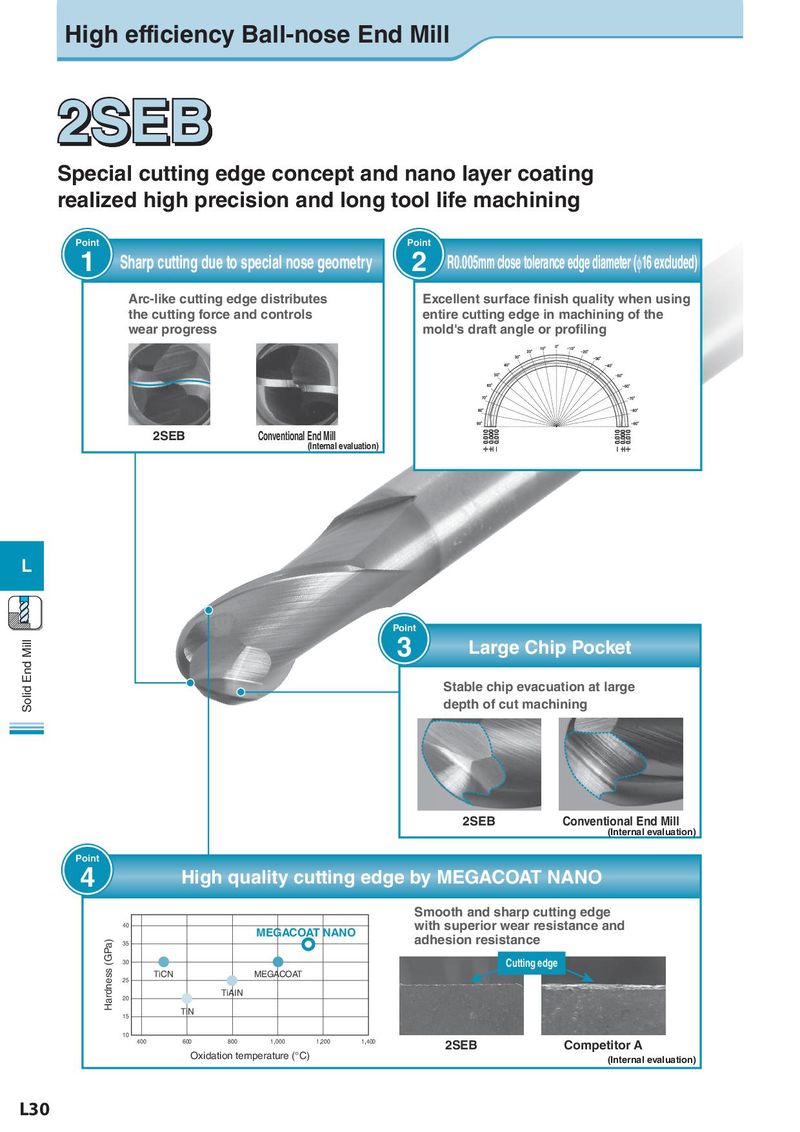

High efficiency Ball-nose End Mill 2SEB Special cutting edge concept and nano layer coating realized high precision and long tool life machining Point Point 1 Sharp cutting due to special nose geometry 2 R0.005mm close tolerance edge diameter (φ16 excluded) Arc-like cutting edge distributes Excellent surface nish quality when using the cutting force and controls entire cutting edge in machining of the wear progress mold's draft angle or pro ling 2SEB Conventional End Mill (Internal evaluation) L Point Solid End Mill 3 Large Chip Pocket Stable chip evacuation at large depth of cut machining 2SEB Conventional End Mill (Internal evaluation) Point 4 High quality cutting edge by MEGACOAT NANO Smooth and sharp cutting edge 40 MEGACOAT NANO with superior wear resistance and Hardness (GPa) 35 adhesion resistance 30 Cutting edge 25 TiCN MEGACOAT 20 TiAIN 15 TiN 10 400 600 800 1,000 1,200 1,400 2SEB Competitor A Oxidation temperature (°C) (Internal evaluation) L30