Основной каталог Kyocera 2016-2017 - страница 623

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

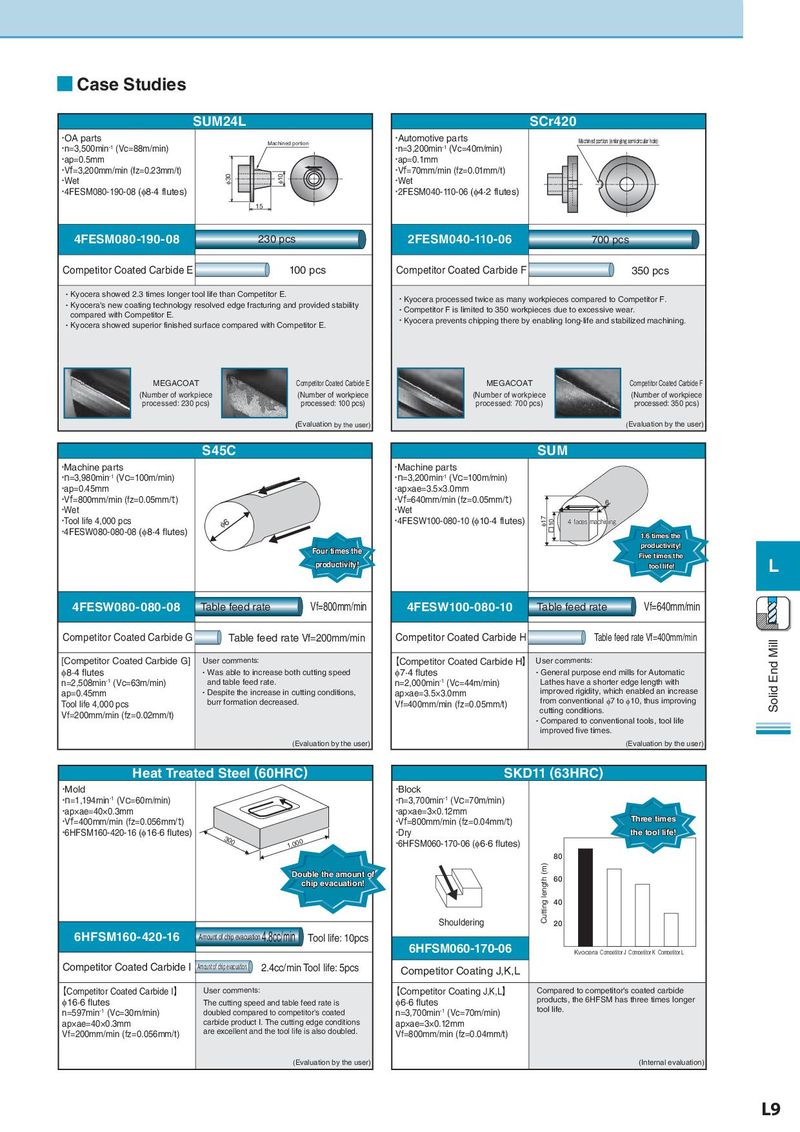

■ Case Studies SUM24L SCr420 ・OA parts Machined portion ・Automotive parts Machined portion (enlarging semicircular hole) ・n=3,500min-1 (Vc=88m/min) ・n=3,200min-1 (Vc=40m/min) ・ap=0.5mm ・ap=0.1mm ・Vf=3,200mm/min (fz=0.23mm/t) φ30 φ10 ・Vf=70mm/min (fz=0.01mm/t) ・Wet ・Wet ・4FESM080-190-08 (φ8·4 flutes) ・2FESM040-110-06 (φ4·2 flutes) 15 4FESM080-190-08 230 pcs 2FESM040-110-06 700 pcs Competitor Coated Carbide E 100 pcs Competitor Coated Carbide F 350 pcs ・Kyocera showed 2.3 times longer tool life than Competitor E. ・Kyocera processed twice as many workpieces compared to Competitor F. ・Kyocera's new coating technology resolved edge fracturing and provided stability ・Competitor F is limited to 350 workpieces due to excessive wear. compared with Competitor E. ・Kyocera prevents chipping there by enabling long-life and stabilized machining. ・Kyocera showed superior finished surface compared with Competitor E. MEGACOAT Competitor Coated Carbide E MEGACOAT Competitor Coated Carbide F (Number of workpiece (Number of workpiece (Number of workpiece (Number of workpiece processed: 230 pcs) processed: 100 pcs) processed: 700 pcs) processed: 350 pcs) (Evaluation by the user) (Evaluation by the user) S45C SUM ・Machine parts ・Machine parts ・n=3,980min-1 (Vc=100m/min) ・n=3,200min-1 (Vc=100m/min) ・ap=0.45mm ・ap×ae=3.5×3.0mm ・Vf=800mm/min (fz=0.05mm/t) ・Vf=640mm/min (fz=0.05mmt/ ) 6 ・Wet ・Wet ・Tool life 4,000 pcs φ6 ・4FESW100-080-10 (φ10·4 flutes) φ17 □10 4 faces machining ・4FESW080-080-08 (φ8·4 flutes) 1.6 times the Four times the productivity! Five times the L productivity! tool life! 4FESW080-080-08 Table feed rate Vf=800mm/min 4FESW100-080-10 Table feed rate Vf=640mm/min Competitor Coated Carbide G Table feed rate Vf=200mm/min Competitor Coated Carbide H Table feed rate Vf=400mm/min Solid End Mill [Competitor Coated Carbide G] User comments: 【Competitor Coated Carbide H】 User comments: φ8·4 flutes ・Was able to increase both cutting speed φ7·4 flutes ・General purpose end mills for Automatic n=2,508min-1 (Vc=63m/min) and table feed rate. n=2,000min-1 (Vc=44m/min) Lathes have a shorter edge length with ap=0.45mm ・Despite the increase in cutting conditions, ap×ae=3.5×3.0mm improved rigidity, which enabled an increase Tool life 4,000 pcs burr formation decreased. Vf=400mm/min (fz=0.05mm/t) from conventional φ7 to φ10, thus improving Vf=200mm/min (fz=0.02mm/t) cutting conditions. ・Compared to conventional tools, tool life improved five times. (Evaluation by the user) (Evaluation by the user) Heat Treated Steel (60HRC) SKD11 (63HRC) ・Mold ・Block ・n=1,194min-1 (Vc=60m/min) ・n=3,700min-1 (Vc=70m/min) ・ap×ae=40×0.3mm ・ap×ae=3×0.12mm Three times ・Vf=400mm/min (fz=0.056mm/t) ・Vf=800mm/min (fz=0.04mmt/ ) ・6HFSM160-420-16 (φ16·6 flutes) 300 ・Dry the tool life! 1,000 ・6HFSM060-170-06 (φ6·6 flutes) 80 Double the amount of Cutting length (m) 60 chip evacuation! 40 Shouldering 20 6HFSM160-420-16 Amount of chip evacuation 4.8cc/min Tool life: 10pcs 6HFSM060-170-06 Kyocera Competitor J Competitor K Competitor L Competitor Coated Carbide I Amount of chip evacuation 2.4cc/min Tool life: 5pcs Competitor Coating J,K,L 【Competitor Coated Carbide I】 User comments: 【Competitor Coating J,K,L】 Compared to competitor's coated carbide φ16·6 flutes The cutting speed and table feed rate is φ6·6 flutes products, the 6HFSM has three times longer n=597min-1 (Vc=30m/min) doubled compared to competitor's coated n=3,700min-1 (Vc=70m/min) tool life. ap×ae=40×0.3mm carbide product I. The cutting edge conditions ap×ae=3×0.12mm Vf=200mm/min (fz=0.056mm/t) are excellent and the tool life is also doubled. Vf=800mm/min (fz=0.04mm/t) (Evaluation by the user) (Internal evaluation) L9