Основной каталог Kyocera 2016-2017 - страница 622

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

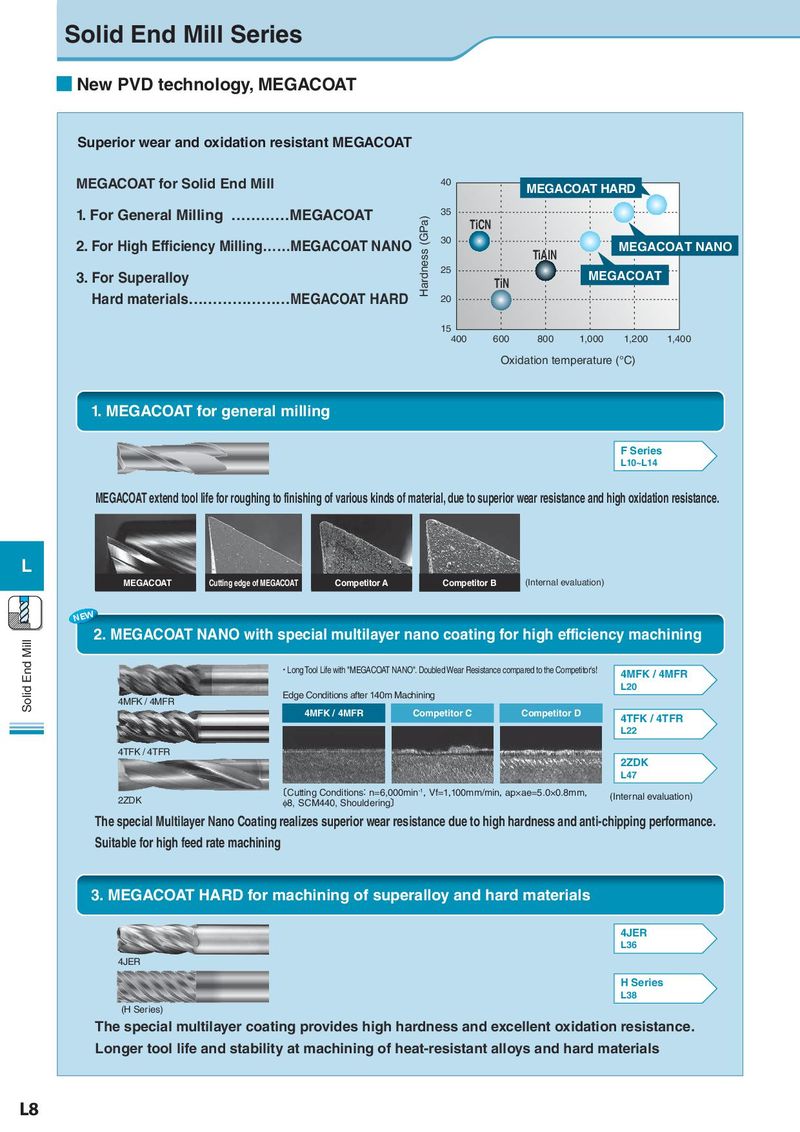

Solid End Mill Series ■ New PVD technology, MEGACOAT Superior wear and oxidation resistant MEGACOAT MEGACOAT for Solid End Mill 40 MEGACOAT HARD 1. For General Milling …………MEGACOAT Hardness (GPa) 35 TiCN 2. For High Efficiency Milling……MEGACOAT NANO 30 MEGACOAT NANO TiAlN 3. For Superalloy 25 MEGACOAT TiN Hard materials…………………MEGACOAT HARD 20 15 400 600 800 1,000 1,200 1,400 Oxidation temperature (°C) 1. MEGACOAT for general milling F Series L10~L14 MEGACOAT extend tool life for roughing to finishing of various kinds of material, due to superior wear resistance and high oxidation resistance. L MEGACOAT Cutting edge of MEGACOAT Competitor A Competitor B (Internal evaluation) 1(: Solid End Mill 2. MEGACOAT NANO with special multilayer nano coating for high efficiency machining ・Long Tool Life with "MEGACOAT NANO". Doubled Wear Resistance compared to the Competitor's! 4MFK / 4MFR Edge Conditions after 140m Machining L20 4MFK / 4MFR 4MFK / 4MFR Competitor C Competitor D 4TFK / 4TFR L22 4TFK / 4TFR 2ZDK L47 2ZDK 〔Cutting Conditions:n=6,000min-1, Vf=1,100mm/min, ap×ae=5.0×0.8mm, (Internal evaluation) φ8, SCM440, Shouldering〕 The special Multilayer Nano Coating realizes superior wear resistance due to high hardness and anti-chipping performance. Suitable for high feed rate machining 3. MEGACOAT HARD for machining of superalloy and hard materials 4JER L36 4JER H Series L38 (H Series) The special multilayer coating provides high hardness and excellent oxidation resistance. Longer tool life and stability at machining of heat-resistant alloys and hard materials L8