Основной каталог Kyocera 2016-2017 - страница 620

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

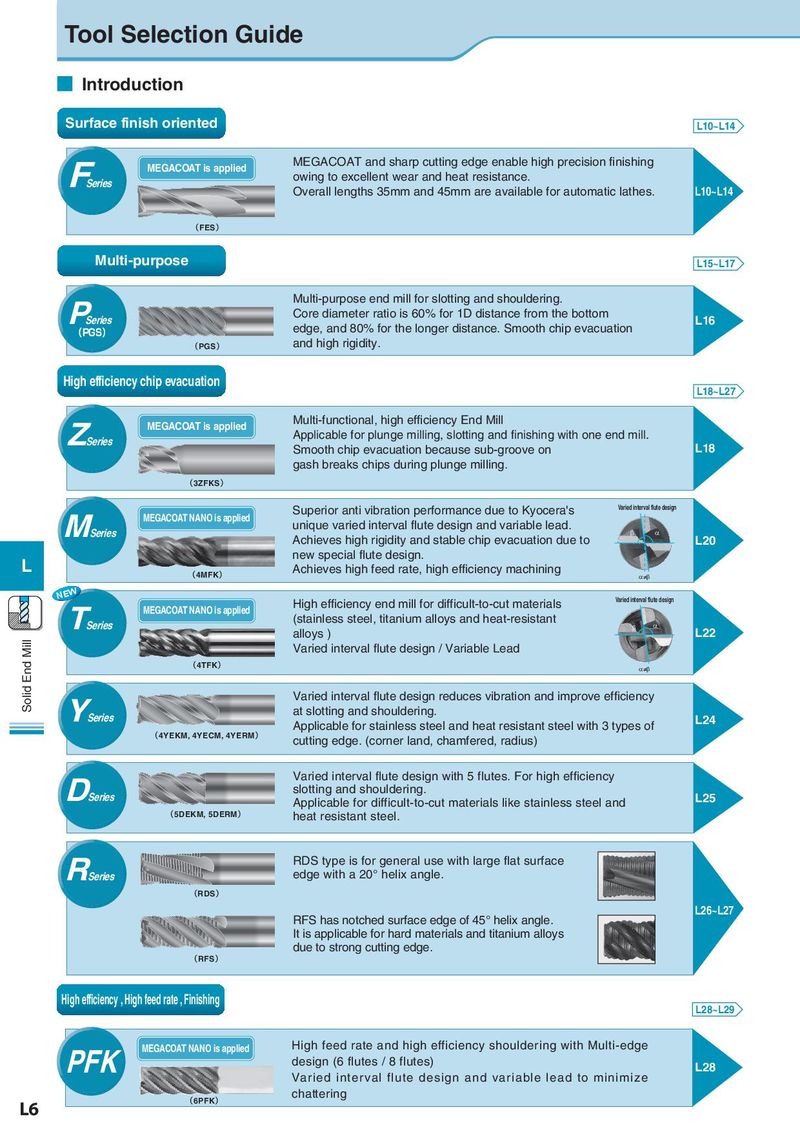

Tool Selection Guide ■ Introduction Surface finish oriented L10~L14 FSeries MEGACOAT is applied MEGACOAT and sharp cutting edge enable high precision finishing owing to excellent wear and heat resistance. Overall lengths 35mm and 45mm are available for automatic lathes. L10~L14 (FES) Multi-purpose L15~L17 PSeries Multi-purpose end mill for slotting and shouldering. Core diameter ratio is 60% for 1D distance from the bottom L16 (PGS) edge, and 80% for the longer distance. Smooth chip evacuation (PGS) and high rigidity. High efficiency chip evacuation L18~L27 ZSeries MEGACOAT is applied Multi-functional, high efficiency End Mill Applicable for plunge milling, slotting and finishing with one end mill. Smooth chip evacuation because sub-groove on L18 gash breaks chips during plunge milling. (3ZFKS) Superior anti vibration performance due to Kyocera's Varied interval flute design MSeries MEGACOAT NANO is applied unique varied interval flute design and variable lead. Achieves high rigidity and stable chip evacuation due to β α L20 L new special flute design. (4MFK) Achieves high feed rate, high efficiency machining α≠β 1(: High efficiency end mill for difficult-to-cut materials Varied interval flute design TSeries MEGACOAT NANO is applied (stainless steel, titanium alloys and heat-resistant alloys ) β α L22 Solid End Mill Varied interval flute design / Variable Lead (4TFK) α≠β YSeries Varied interval flute design reduces vibration and improve efficiency at slotting and shouldering. L24 Applicable for stainless steel and heat resistant steel with 3 types of (4YEKM, 4YECM, 4YERM) cutting edge. (corner land, chamfered, radius) DSeries Varied interval flute design with 5 flutes. For high efficiency slotting and shouldering. L25 Applicable for difficult-to-cut materials like stainless steel and (5DEKM, 5DERM) heat resistant steel. RSeries RDS type is for general use with large flat surface edge with a 20° helix angle. (RDS) RFS has notched surface edge of 45° helix angle. L26~L27 It is applicable for hard materials and titanium alloys due to strong cutting edge. (RFS) High efficiency , High feed rate , Finishing L28~L29 PFK MEGACOAT NANO is applied High feed rate and high efficiency shouldering with Multi-edge design (6 flutes / 8 flutes) L28 Varied interval flute design and variable lead to minimize (6PFK) chattering L6