Основной каталог Kyocera 2016-2017 - страница 619

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

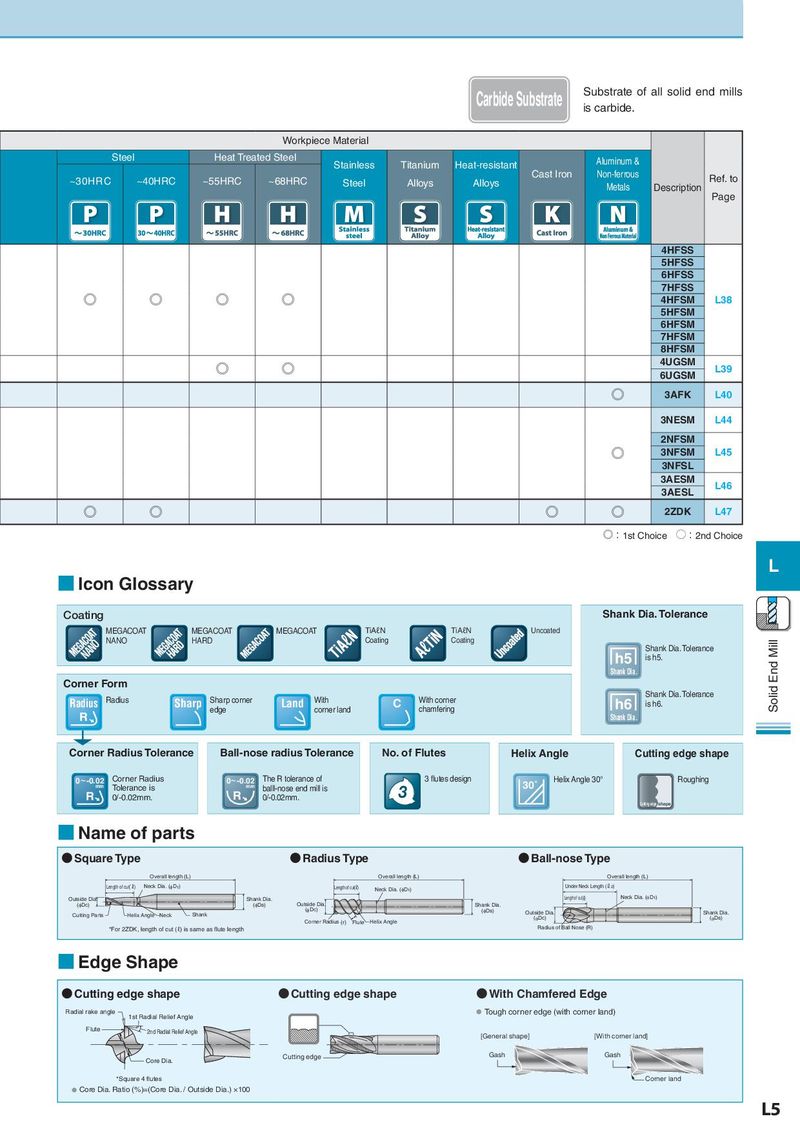

Carbide Substrate Substrate of all solid end mills is carbide. Workpiece Material Steel Heat Treated Steel Stainless Titanium Heat-resistant Aluminum & ~30HRC ~40HRC ~55HRC ~68HRC Steel Alloys Alloys Cast Iron Non-ferrous Ref. to Metals Description Page 4HFSS 5HFSS 6HFSS 7HFSS 0 0 0 0 4HFSM L38 5HFSM 6HFSM 7HFSM 8HFSM 0 0 4UGSM L39 6UGSM 0 3AFK L40 3NESM L44 2NFSM 0 3NFSM L45 3NFSL 3AESM L46 3AESL 0 0 0 0 2ZDK L47 0:1st Choice O:2nd Choice L ■ Icon Glossary Coating Shank Dia. Tolerance MEGACOAT MEGACOAT MEGACOAT TiAℓN TiAℓN Uncoated NANO NANO HARD Coating Coating Solid End Mill h5 Shank Dia. Tolerance is h5. Shank Dia. Corner Form Radius Sharp corner With With corner h6 Shank Dia. Tolerance Radius Sharp edge Land corner land C chamfering is h6. R Shank Dia. Corner Radius Tolerance Ball-nose radius Tolerance No. of Flutes Helix Angle Cutting edge shape 0 ~ -0.02 Corner Radius 0 ~ -0.02 The R tolerance of 3 utes design 30˚ Helix Angle 30° Roughing mm Tolerance is mm balll-nose end mill is 3 R 0/-0.02mm. R 0/-0.02mm. Cutting edge shape ■ Name of parts ● Square Type ● Radius Type ● Ball-nose Type Overall length (L) Overall length (L) Overall length (L) Length of cut(*ℓ) Neck Dia. (φD1) Length of cut(ℓ) Neck Dia. (φD1) Under Neck Length (ℓ2) Outside Dia. Shank Dia. Length of cut(ℓ) Neck Dia. (φD1) (φDc) (φDs) Outside Dia. Shank Dia. (φDc) (φDs) Outside Dia. Shank Dia. Cutting Parts Helix Angle Neck Shank (φDc) (φDs) Corner Radius (r) Flute Helix Angle *For 2ZDK, length of cut (ℓ) is same as flute length Radius of Ball Nose (R) ■ Edge Shape ● Cutting edge shape ● Cutting edge shape ● With Chamfered Edge Radial rake angle 1st Radial Relief Angle ● Tough corner edge (with corner land) Flute 2nd Radial Relief Angle [General shape] [With corner land] Core Dia. Cutting edge Gash Gash *Square 4 utes Corner land ● Core Dia. Ratio (%)=(Core Dia. / Outside Dia.) ×100 L5