Основной каталог Kyocera 2016-2017 - страница 618

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

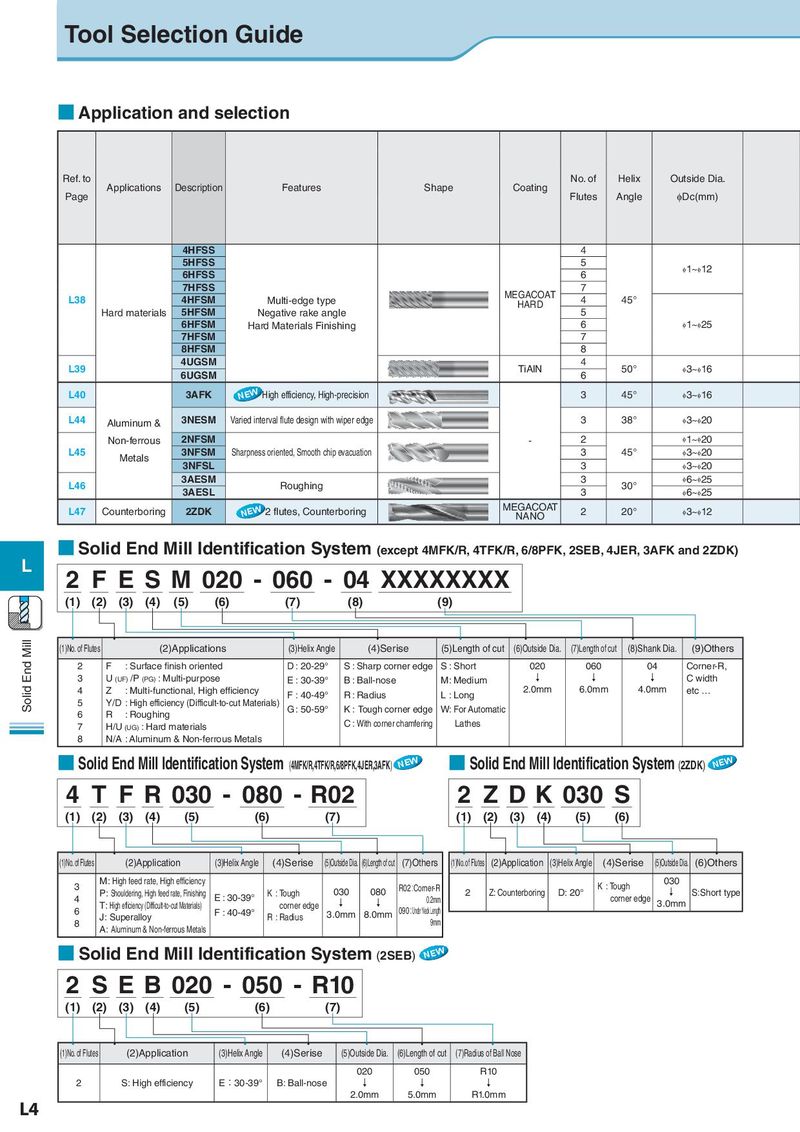

Tool Selection Guide ■ Application and selection Ref. to Applications Description Features Shape Coating No. of Helix Outside Dia. Page Flutes Angle φDc(mm) 4HFSS 4 5HFSS 5 φ1~φ12 6HFSS 6 7HFSS MEGACOAT 7 L38 4HFSM Multi-edge type HARD 4 45° Hard materials 5HFSM Negative rake angle 5 6HFSM Hard Materials Finishing 6 φ1~φ25 7HFSM 7 8HFSM 8 L39 4UGSM TiAlN 4 50° φ3~φ16 6UGSM 6 L40 3AFK 1(: High efficiency, High-precision 3 45° φ3~φ16 L44 Aluminum & 3NESM Varied interval flute design with wiper edge 3 38° φ3~φ20 Non-ferrous 2NFSM - 2 φ1~φ20 L45 Metals 3NFSM Sharpness oriented, Smooth chip evacuation 3 45° φ3~φ20 3NFSL 3 φ3~φ20 L46 3AESM Roughing 3 30° φ6~φ25 3AESL 3 φ6~φ25 L47 Counterboring 2ZDK 1(: 2 flutes, Counterboring MEGACOAT 2 20° φ3~φ12 NANO ■ Solid End Mill Identification System (except 4MFK/R, 4TFK/R, 6/8PFK, 2SEB, 4JER, 3AFK and 2ZDK) L 2 F E S M 020 - 060 - 04 XXXXXXXX (1) (2) (3) (4) (5) (6) (7) (8) (9) Solid End Mill (1)No. of Flutes (2)Applications (3)Helix Angle (4)Serise (5)Length of cut (6)Outside Dia. (7)Length of cut (8)Shank Dia. (9)Others 2 F : Surface finish oriented D : 20-29° S : Sharp corner edge S :Short 020 060 04 Corner-R, 3 U (UF) /P (PG) : Multi-purpose E : 30-39° B : Ball-nose M: Medium ↓ ↓ ↓ C width 4 Z : Multi-functional, High efficiency F : 40-49° R : Radius L :Long 2.0mm 6.0mm 4.0mm etc … 5 Y/D :High efficiency (Difficult-to-cut Materials) G : 50-59° K :Tough corner edge W: For Automatic 6 R : Roughing 7 H/U (UG) : Hard materials C :With corner chamfering Lathes 8 N/A :Aluminum & Non-ferrous Metals ■ Solid End Mill Identification System (4MFK/R,4TFK/R,6/8PFK,4JER,3AFK) 1(: ■ Solid End Mill Identification System (2ZDK) 1(: 4 T F R 030 - 080 - R02 2 Z D K 030 S (1) (2) (3) (4) (5) (6) (7) (1) (2) (3) (4) (5) (6) (1)No. of Flutes (2)Application (3)Helix Angle (4)Serise (5)Outside Dia. (6)Length of cut (7)Others (1)No. of Flutes (2)Application (3)Helix Angle (4)Serise (5)Outside Dia. (6)Others 3 M: High feed rate, High efficiency R02:Corner-R K : Tough 030 4 P: Shouldering, High feed rate, Finishing E : 30-39° K : Tough 030 080 0.2mm 2 Z: Counterboring D: 20° corner edge ↓ S:Short type T: High efficiency (Difficult-to-cut Materials) corner edge ↓ ↓ 090:Under Neck Length 3.0mm 6 J: Superalloy F : 40-49° R : Radius 3.0mm 8.0mm 8 A: Aluminum & Non-ferrous Metals 9mm ■ Solid End Mill Identification System (2SEB) 1(: 2 S E B 020 - 050 - R10 (1) (2) (3) (4) (5) (6) (7) (1)No. of Flutes (2)Application (3)Helix Angle (4)Serise (5)Outside Dia. (6)Length of cut (7)Radius of Ball Nose 020 050 R10 2 S: High efficiency E:30-39° B: Ball-nose ↓ ↓ ↓ 2.0mm 5.0mm R1.0mm L4