Основной каталог Kyocera 2016-2017 - страница 612

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

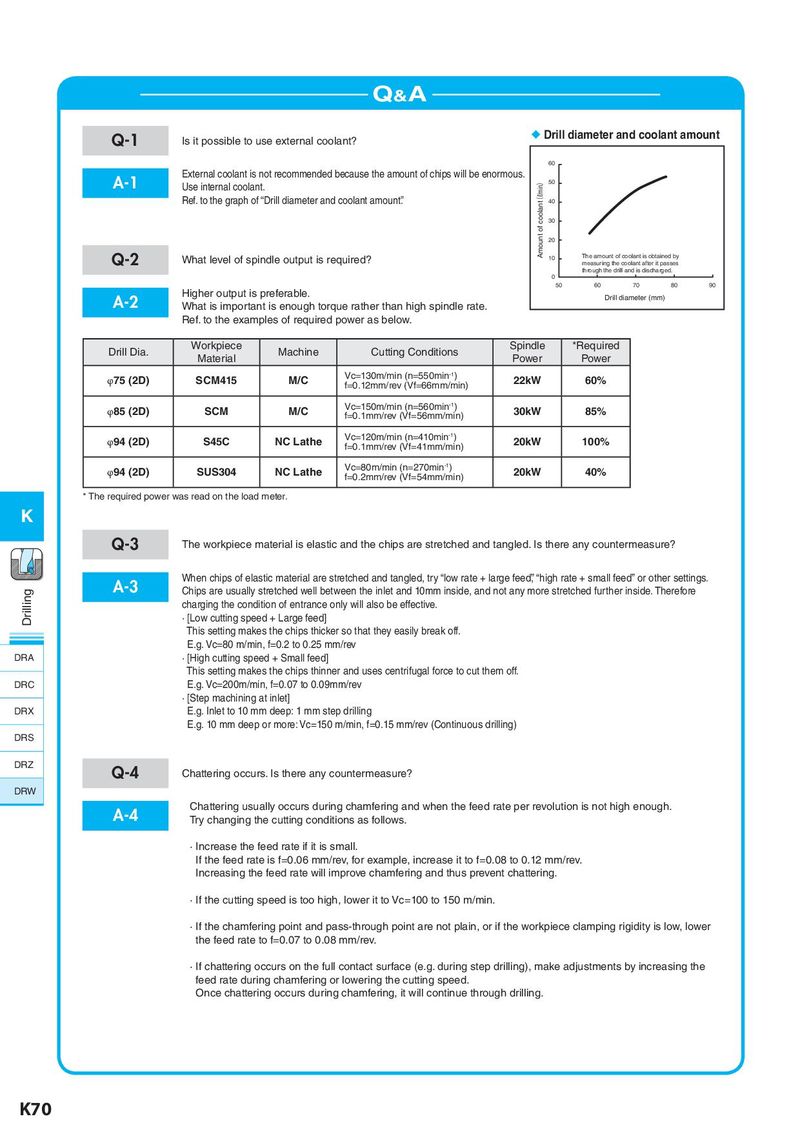

Q&A Q-1 Is it possible to use external coolant? Drill diameter and coolant amount 60 A-1 External coolant is not recommended because the amount of chips will be enormous. Use internal coolant. Amount of coolant(ℓ/min) 50 Ref. to the graph of “Drill diameter and coolant amount”. 40 30 20 Q-2 What level of spindle output is required? 10 The amount of coolant is obtained by measuring the coolant after it passes through the drill and is discharged. 0 50 60 70 80 90 A-2 Higher output is preferable. Drill diameter (mm) What is important is enough torque rather than high spindle rate. Ref. to the examples of required power as below. Drill Dia. Workpiece Machine Cutting Conditions Spindle *Required Material Power Power φ75 (2D) SCM415 M/C Vc=130m/min (n=550min-1) 22kW 60% f=0.12mm/rev (Vf=66mm/min) φ85 (2D) SCM M/C Vc=150m/min (n=560min-1) 30kW 85% f=0.1mm/rev (Vf=56mm/min) φ94 (2D) S45C NC Lathe Vc=120m/min (n=410min-1) 20kW 100% f=0.1mm/rev (Vf=41mm/min) φ94 (2D) SUS304 NC Lathe Vc=80m/min (n=270min-1) 20kW 40% f=0.2mm/rev (Vf=54mm/min) * The required power was read on the load meter. K Q-3 The workpiece material is elastic and the chips are stretched and tangled. Is there any countermeasure? A-3 When chips of elastic material are stretched and tangled, try “low rate + large feed”, “high rate + small feed” or other settings. Drilling Chips are usually stretched well between the inlet and 10mm inside, and not any more stretched further inside. Therefore charging the condition of entrance only will also be effective. · [Low cutting speed + Large feed] This setting makes the chips thicker so that they easily break off. E.g. Vc=80 m/min, f=0.2 to 0.25 mm/rev DRA · [High cutting speed + Small feed] This setting makes the chips thinner and uses centrifugal force to cut them off. DRC E.g. Vc=200m/min, f=0.07 to 0.09mm/rev · [Step machining at inlet] DRX E.g. Inlet to 10 mm deep: 1 mm step drilling E.g. 10 mm deep or more: Vc=150 m/min, f=0.15 mm/rev (Continuous drilling) DRS DRZ Q-4 Chattering occurs. Is there any countermeasure? DRW A-4 Chattering usually occurs during chamfering and when the feed rate per revolution is not high enough. Try changing the cutting conditions as follows. · Increase the feed rate if it is small. If the feed rate is f=0.06 mm/rev, for example, increase it to f=0.08 to 0.12 mm/rev. Increasing the feed rate will improve chamfering and thus prevent chattering. · If the cutting speed is too high, lower it to Vc=100 to 150 m/min. · If the chamfering point and pass-through point are not plain, or if the workpiece clamping rigidity is low, lower the feed rate to f=0.07 to 0.08 mm/rev. · If chattering occurs on the full contact surface (e.g. during step drilling), make adjustments by increasing the feed rate during chamfering or lowering the cutting speed. Once chattering occurs during chamfering, it will continue through drilling. K70