Основной каталог Kyocera 2016-2017 - страница 613

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

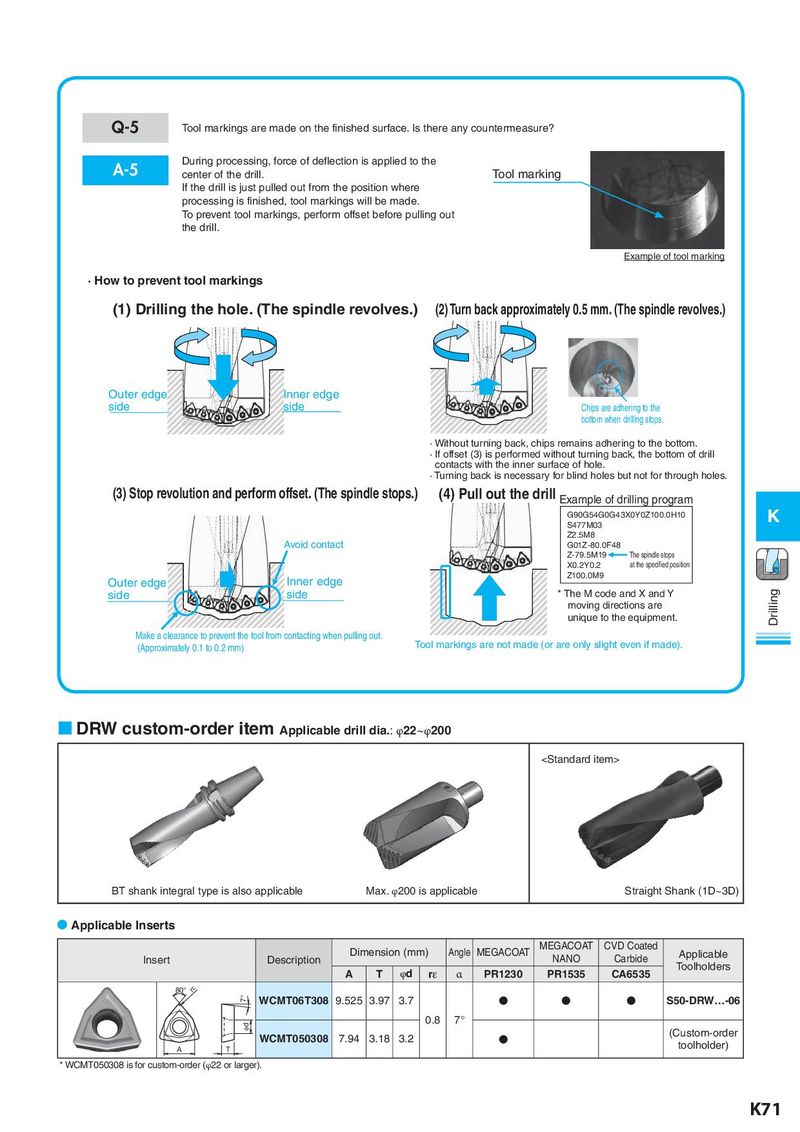

Q-5 Tool markings are made on the finished surface. Is there any countermeasure?

A-5 During processing, force of deflection is applied to the

center of the drill. Tool marking

If the drill is just pulled out from the position where

processing is finished, tool markings will be made.

To prevent tool markings, perform offset before pulling out

the drill.

Example of tool marking

· How to prevent tool markings

(1) Drilling the hole. (The spindle revolves.) (2) Turn back approximately 0.5 mm. (The spindle revolves.)

Outer edge Inner edge

side side Chips are adhering to the

bottom when drilling stops.

· Without turning back, chips remains adhering to the bottom.

· If offset (3) is performed without turning back, the bottom of drill

contacts with the inner surface of hole.

· Turning back is necessary for blind holes but not for through holes.

(3) Stop revolution and perform offset. (The spindle stops.) (4) Pull out the drill Example of drilling program

G90G54G0G43X0Y0Z100.0H10 K

S477M03

Z2.5M8

Avoid contact G01Z -80.0F48

Z-79.5M19 The spindle stops

X0.2Y0.2 at the specified position

Outer edge Inner edge Z100.0M9

side side * The M code and X and Y Drilling

moving directions are

unique to the equipment.

Make a clearance to prevent the tool from contacting when pulling out.

(Approximately 0.1 to 0.2 mm) Tool markings are not made (or are only slight even if made).

DRW custom-order item Applicable drill dia.: φ22~φ200