Основной каталог Kyocera 2016-2017 - страница 576

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

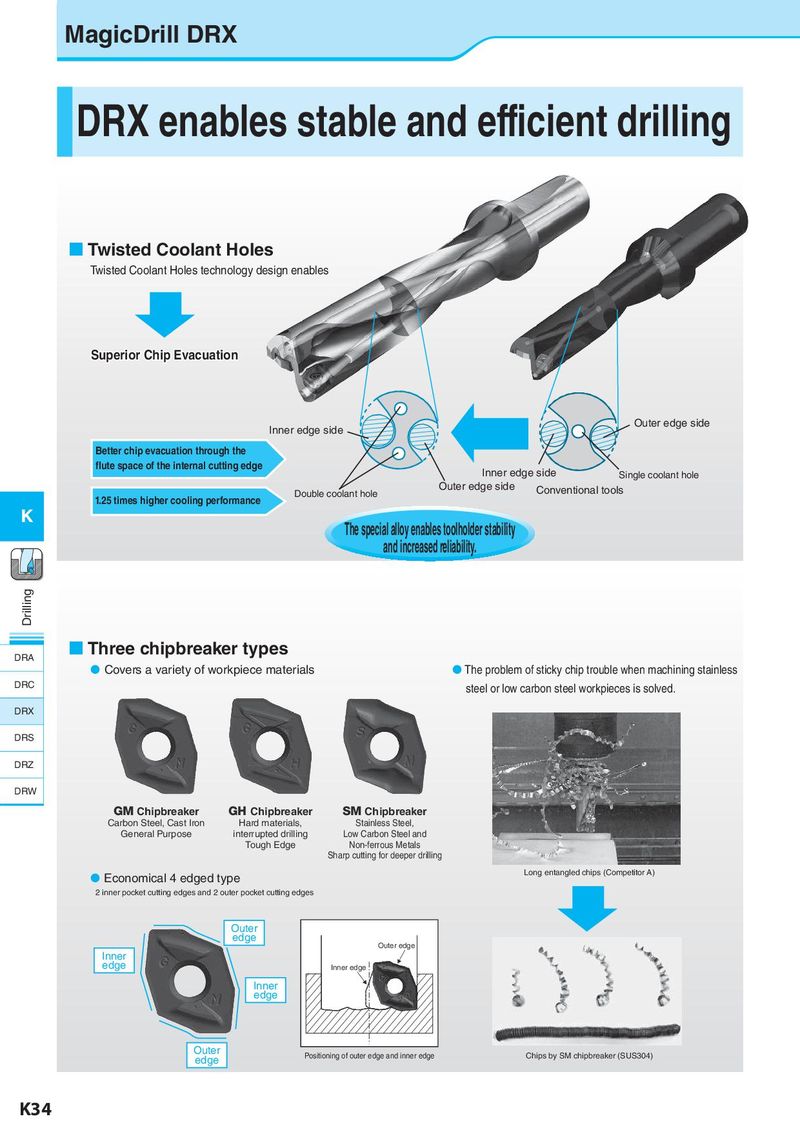

MagicDrill DRX DRX enables stable and efficient drilling Twisted Coolant Holes Twisted Coolant Holes technology design enables Superior Chip Evacuation Inner edge side Outer edge side Better chip evacuation through the flute space of the internal cutting edge Inner edge side Single coolant hole Double coolant hole Outer edge side Conventional tools 1.25 times higher cooling performance K The special alloy enables toolholder stability and increased reliability. Drilling DRA Three chipbreaker types Covers a variety of workpiece materials The problem of sticky chip trouble when machining stainless DRC steel or low carbon steel workpieces is solved. DRX DRS DRZ DRW GM Chipbreaker GH Chipbreaker SM Chipbreaker Carbon Steel, Cast Iron Hard materials, Stainless Steel, General Purpose interrupted drilling Low Carbon Steel and Tough Edge Non-ferrous Metals Sharp cutting for deeper drilling Economical 4 edged type Long entangled chips (Competitor A) 2 inner pocket cutting edges and 2 outer pocket cutting edges Outer edge Outer edge Inner edge Inner edge Inner edge Outer Positioning of outer edge and inner edge Chips by SM chipbreaker (SUS304) edge K34