Основной каталог Kyocera 2016-2017 - страница 577

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

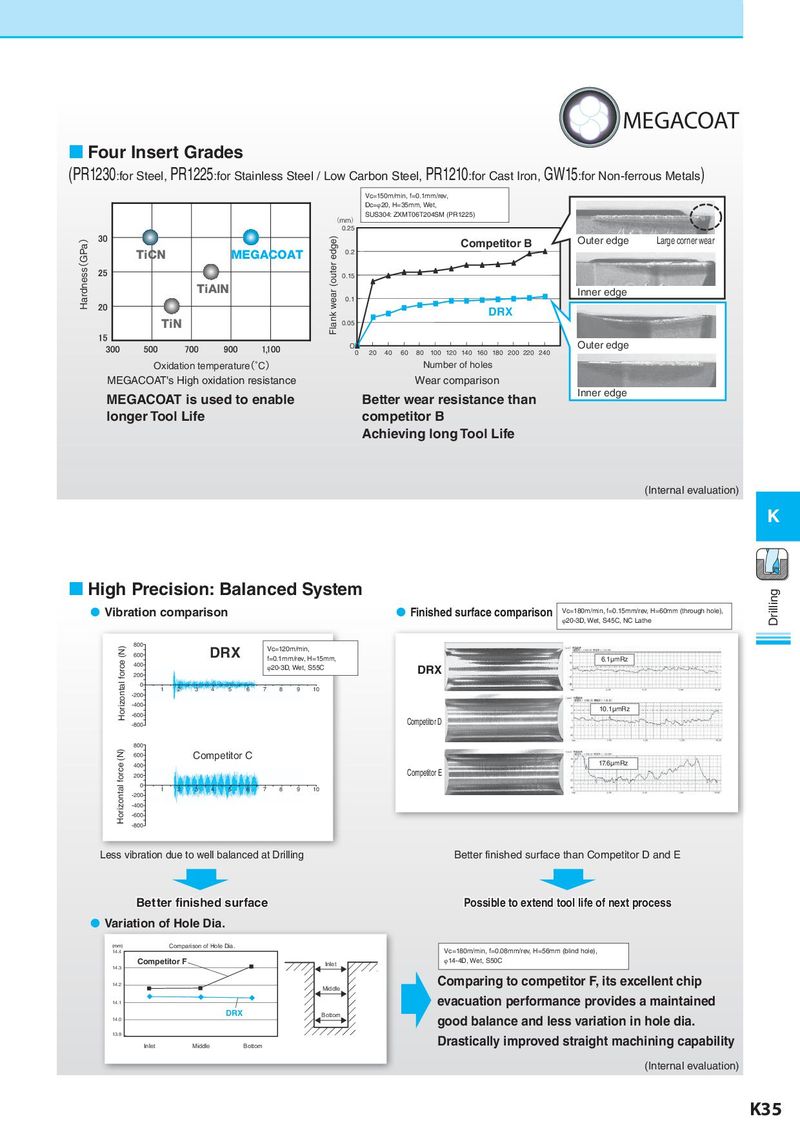

MEGACOAT Four Insert Grades (PR1230:for Steel, PR1225:for Stainless Steel / Low Carbon Steel, PR1210:for Cast Iron, GW15:for Non-ferrous Metals) Vc=150m/min, f=0.1mm/rev, Dc=φ20, H=35mm, Wet, (mm) SUS304: ZXMT06T204SM (PR1225) 0.25 Hardness(GPa) Flank wear (outer edge) Competitor B Outer edge Large corner wear TiCN MEGACOAT 0.2 0.15 TiAlN Inner edge 0.1 DRX TiN 0.05 0 Outer edge 0 20 40 60 80 100 120 140 160 180 200 220 240 Oxidation temperature(°C) Number of holes MEGACOAT's High oxidation resistance Wear comparison MEGACOAT is used to enable Better wear resistance than Inner edge longer Tool Life competitor B Achieving long Tool Life (Internal evaluation) K High Precision: Balanced System Drilling Vibration comparison Finished surface comparison Vc=180m/min, f=0.15mm/rev, H=60mm (through hole), φ20-3D, Wet, S45C, NC Lathe Horizontal force (N) 800 DRX Vc=120m/min, 600 f=0.1mm/rev, H=15mm, 6.1μmRz 400 φ20-3D, Wet, S55C DRX 200 0 1 2 3 4 5 6 7 8 9 10 -200 -400 10.1μmRz -600 -800 Competitor D 800 Horizontal force (N) 600 Competitor C 400 17.6μmRz 200 Competitor E 0 1 2 3 4 5 6 7 8 9 10 -200 -400 -600 -800 Less vibration due to well balanced at Drilling Better finished surface than Competitor D and E Better finished surface Possible to extend tool life of next process Variation of Hole Dia. (mm) Comparison of Hole Dia. 14.4 Vc=180m/min, f=0.08mm/rev, H=56mm (blind hole), Competitor F Inlet φ14-4D, Wet, S50C 14.3 14.2 Middle Comparing to competitor F, its excellent chip 14.1 evacuation performance provides a maintained DRX Bottom good balance and less variation in hole dia. 14.0 13.9 Drastically improved straight machining capability Inlet Middle Bottom (Internal evaluation) K35