Основной каталог Kyocera 2016-2017 - страница 575

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

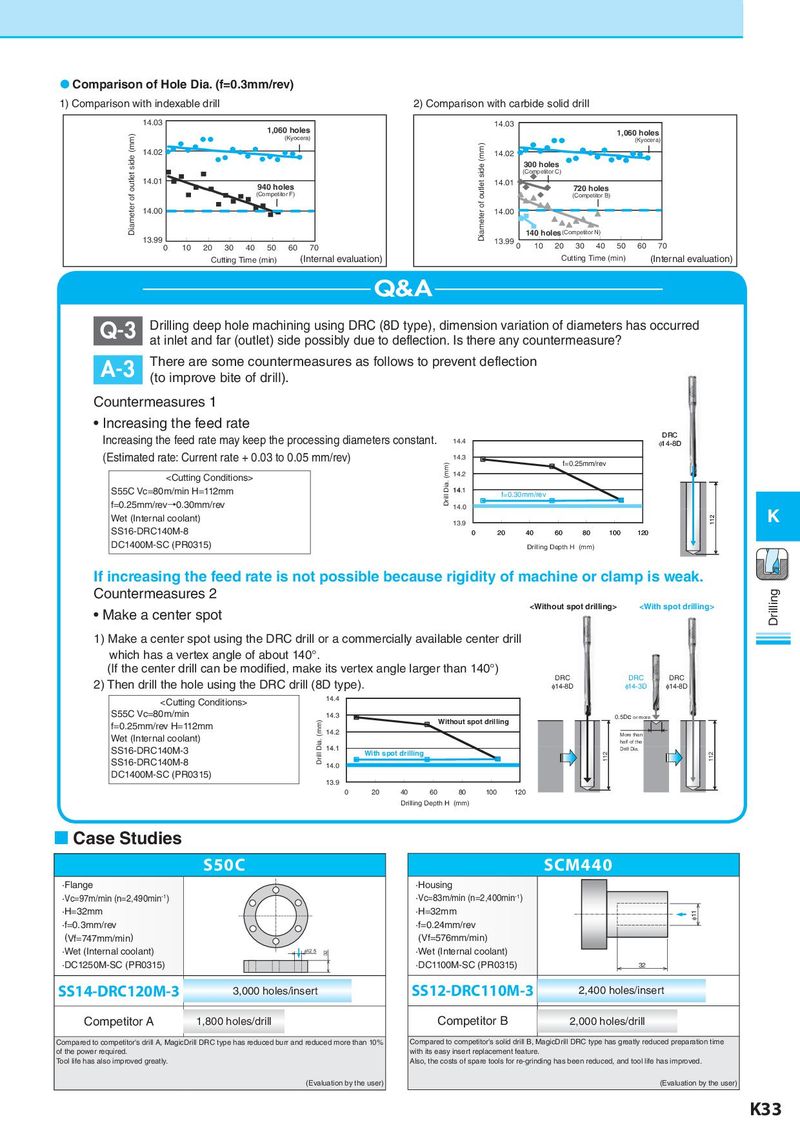

Comparison of Hole Dia. (f=0.3mm/rev)

1) Comparison with indexable drill 2) Comparison with carbide solid drill

14.03 14.03

Diameter of outlet side (mm) 1,060 holes 1,060 holes

(Kyocera) (Kyocera)

14.02 Diameter of outlet side (mm) 14.02

300 holes

(Competitor C)

14.01 940 holes 14.01

(Competitor F) 720 holes

(Competitor B)

14.00 14.00

140 holes (Competitor N)

13.99 13.99 0 10 20 30 40 50 60 70

0 10 20 30 40 50 60 70

Cutting Time (min) (Internal evaluation) Cutting Time (min) (Internal evaluation)

Q&A

Q-3 Drilling deep hole machining using DRC (8D type), dimension variation of diameters has occurred

at inlet and far (outlet) side possibly due to deflection. Is there any countermeasure?

A-3 There are some countermeasures as follows to prevent deflection

(to improve bite of drill).

Countermeasures 1

• Increasing the feed rate

Increasing the feed rate may keep the processing diameters constant. 14.4 DRC

I14-8D

(Estimated rate: Current rate + 0.03 to 0.05 mm/rev) 14.3

Drill Dia. (mm) f=0.25mm/rev