Основной каталог Kyocera 2016-2017 - страница 546

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

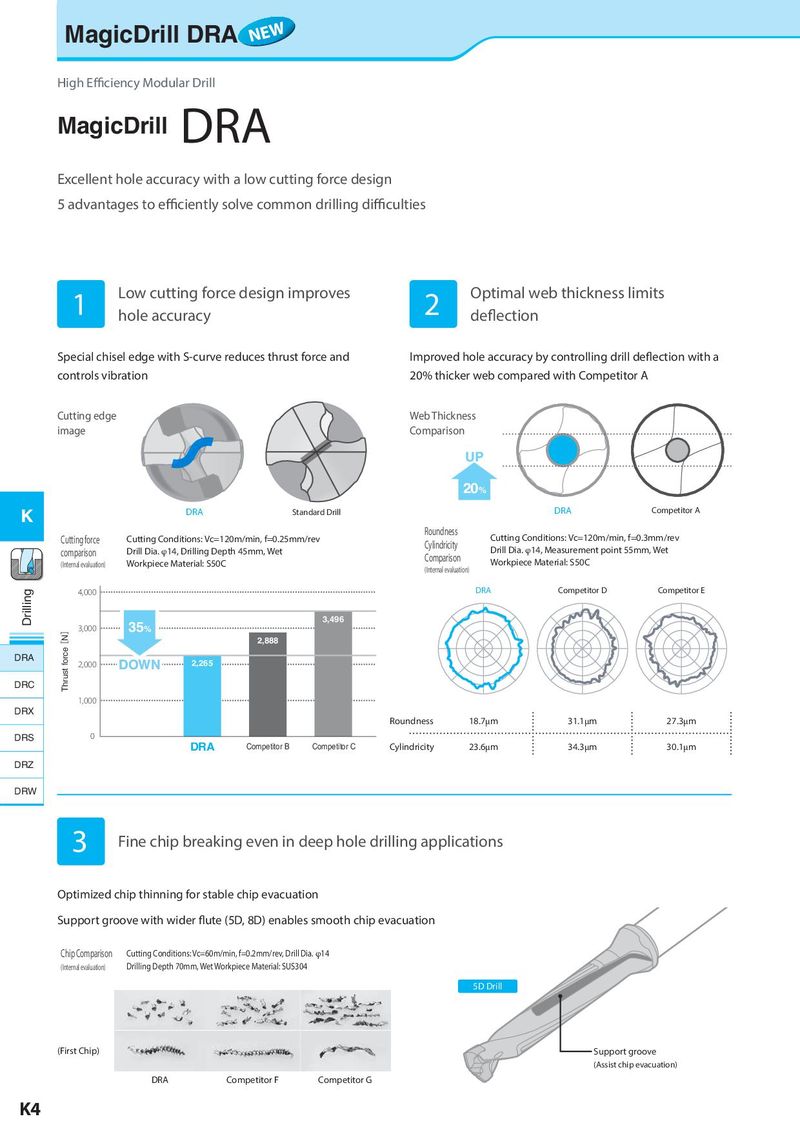

MagicDrill DRA NEW High Efficiency Modular Drill DRA MagicDrill Excellent hole accuracy with a low cutting force design 5 advantages to efficiently solve common drilling difficulties 1 Low cutting force design improves 2 Optimal web thickness limits hole accuracy deflection Special chisel edge with S-curve reduces thrust force and Improved hole accuracy by controlling drill deflection with a controls vibration 20% thicker web compared with Competitor A Cutting edge Web Thickness image Comparison UP 20% K DRA Standard Drill DRA Competitor A Cutting force Cutting Conditions: Vc=120m/min, f=0.25mm/rev Roundness Cutting Conditions: Vc=120m/min, f=0.3mm/rev comparison Drill Dia. φ14, Drilling Depth 45mm, Wet Cylindricity Drill Dia. φ14, Measurement point 55mm, Wet (Internal evaluation) Workpiece Material: S50C Comparison Workpiece Material: S50C (Internal evaluation) Drilling 4,000 DRA Competitor D Competitor E 35% 3,496 Thrust force[N] 3,000 2,888 DRA 2,000 DOWN 2,265 DRC 1,000 DRX Roundness 18.7μm 31.1μm 27.3μm DRS 0 DRA Competitor B Competitor C Cylindricity 23.6μm 34.3μm 30.1μm DRZ DRW 3 Fine chip breaking even in deep hole drilling applications Optimized chip thinning for stable chip evacuation Support groove with wider flute (5D, 8D) enables smooth chip evacuation Chip Comparison Cutting Conditions: Vc=60m/min, f=0.2mm/rev, Drill Dia. φ14 (Internal evaluation) Drilling Depth 70mm, Wet Workpiece Material: SUS304 5D Drill (First Chip) Support groove (Assist chip evacuation) DRA Competitor F Competitor G K4