Основной каталог Kyocera 2016-2017 - страница 547

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

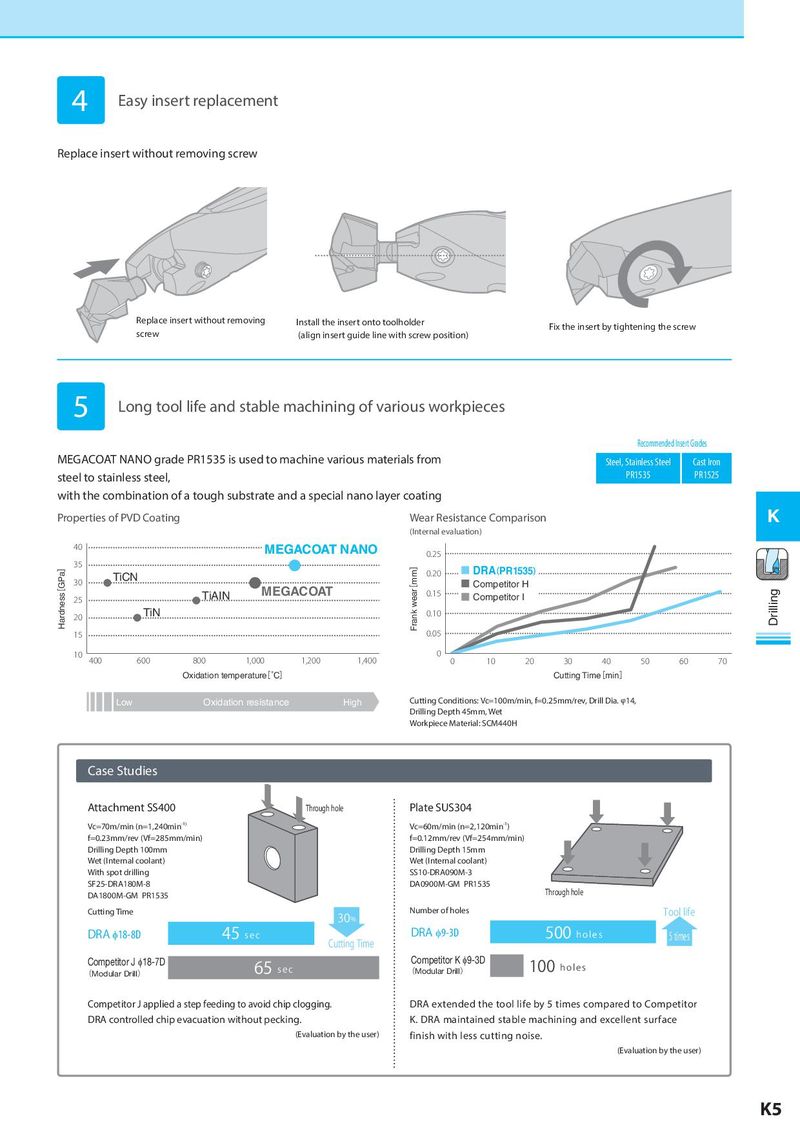

4 Easy insert replacement Replace insert without removing screw Replace insert without removing Install the insert onto toolholder Fix the insert by tightening the screw screw (align insert guide line with screw position) 線幅:0.3mm 破線/線端:丸形 角の形状:ラウンド 5 線分 =0mm L o間n隔g=t0o.6omlmlife and stable machining of various workpieces カラー:KYOCERA_secondary22 Recommended Insert Grades MEGACOAT NANO grade PR1535 is used to machine various materials from Steel, Stainless Steel Cast Iron steel to stainless steel, PR1535 PR1525 with the combination of a tough substrate and a special nano layer coating Properties of PVD Coating Wear Resistance Comparison K (Internal evaluation) 40 MEGACOAT NANO 0.25 Hardness[GPa] 35 Frank wear[mm] DRA(PR1535) TiCN 0.20 30 MEGACOAT Competitor H 25 TiAIN 0.15 Competitor I Drilling 20 TiN 0.10 15 0.05 10 400 600 800 1,000 1,200 1,400 0 0 10 20 30 40 50 60 70 Oxidation temperature[゜C] Cutting Time[min] Low Oxidation resistance High Cutting Conditions: Vc=100m/min, f=0.25mm/rev, Drill Dia. φ14, Drilling Depth 45mm, Wet Workpiece Material: SCM440H Case Studies Attachment SS400 Through hole Plate SUS304 Vc=70m/min (n=1,240min-1) Vc=60m/min (n=2,120min-1) f=0.23mm/rev (Vf=285mm/min) f=0.12mm/rev (Vf=254mm/min) Drilling Depth 100mm Drilling Depth 15mm Wet (Internal coolant) Wet (Internal coolant) With spot drilling SS10-DRA090M-3 SF25-DRA180M-8 DA0900M-GM PR1535 DA1800M-GM PR1535 Through hole CuttttiinnggTTimimee 30% NNuummbbeerroof fhhoolelses Tool life DRA φ18-8D 45 sec Cutting Time DRA φ9-3D 500 holes 5 times Competitor J φ18-7D 65 sec Competitor K φ9-3D 100 holes (Modular Drill) (Modular Drill) Competitor J applied a step feeding to avoid chip clogging. DRA extended the tool life by 5 times compared to Competitor DRA controlled chip evacuation without pecking. K. DRA maintained stable machining and excellent surface (Evaluation by the user) finish with less cutting noise. (Evaluation by the user) K5