Основной каталог Kyocera 2016-2017 - страница 545

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

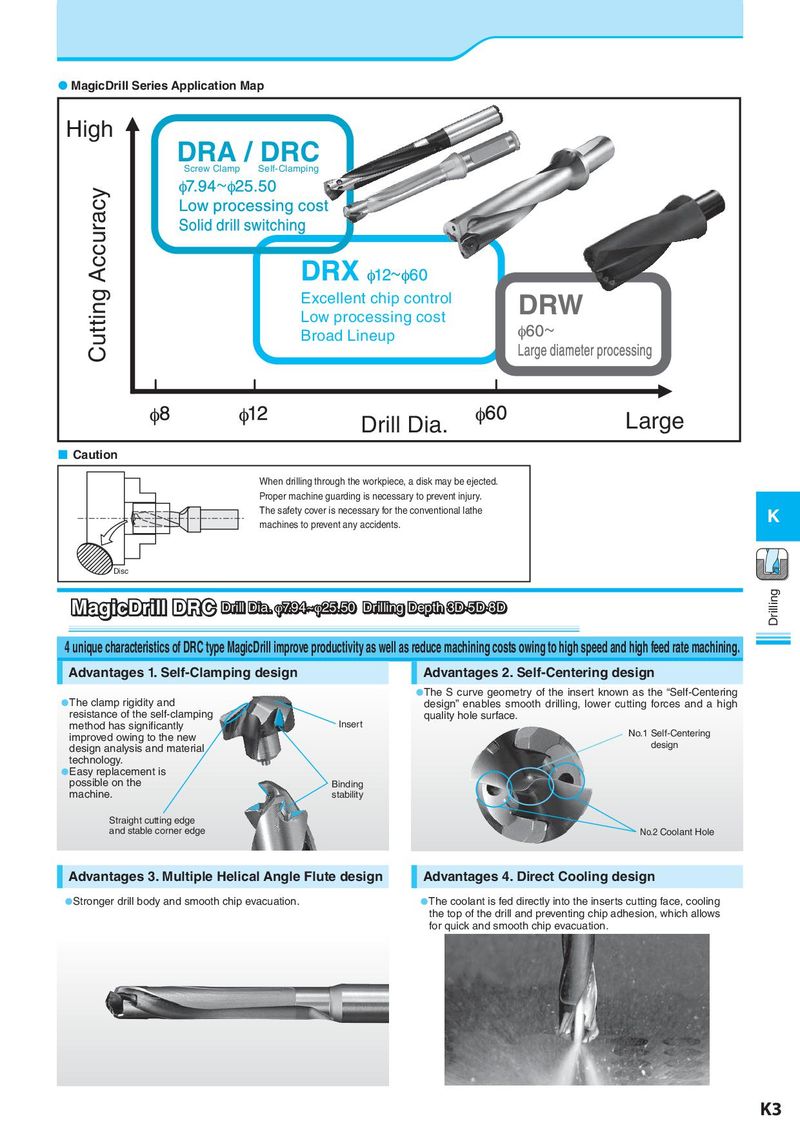

MagicDrill Series Application Map High DRA / DRC Screw Clamp Self-Clamping Cutting Accuracy Excellent chip control DRW Low processing cost Broad Lineup Drill Dia. Large Caution When drilling through the workpiece, a disk may be ejected. Proper machine guarding is necessary to prevent injury. The safety cover is necessary for the conventional lathe K machines to prevent any accidents. Disc MagicDrill DRC Drill Dia. φ7.94~φ25.50 Drilling Depth 3D·5D·8D Drilling 4 unique characteristics of DRC type MagicDrill improve productivity as well as reduce machining costs owing to high speed and high feed rate machining. Advantages 1. Self-Clamping design Advantages 2. Self-Centering design The S curve geometry of the insert known as the “Self-Centering The clamp rigidity and design” enables smooth drilling, lower cutting forces and a high resistance of the self-clamping quality hole surface. method has significantly Insert improved owing to the new No.1 Self-Centering design analysis and material design technology. Easy replacement is possible on the Binding machine. stability Straight cutting edge and stable corner edge No.2 Coolant Hole Advantages 3. Multiple Helical Angle Flute design Advantages 4. Direct Cooling design Stronger drill body and smooth chip evacuation. The coolant is fed directly into the inserts cutting face, cooling the top of the drill and preventing chip adhesion, which allows for quick and smooth chip evacuation. K3