Основной каталог Kyocera 2016-2017 - страница 471

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

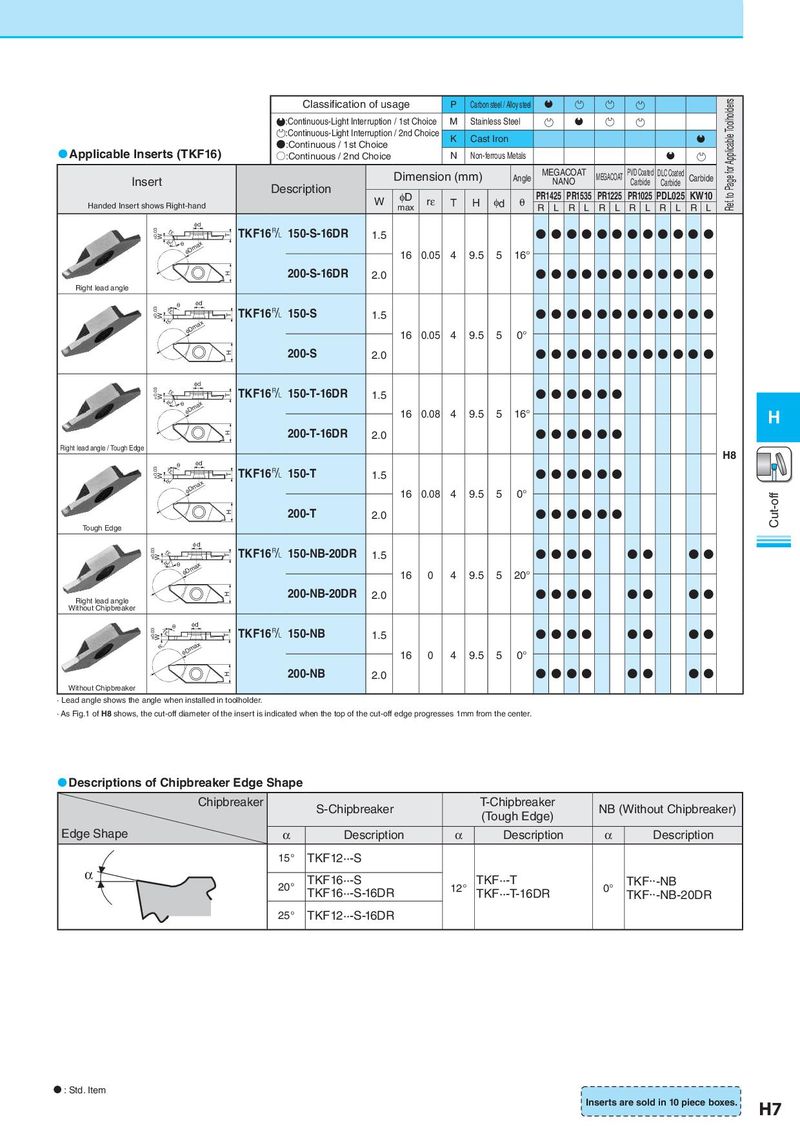

Classification of usage P Carbon steel / Alloy steel Q Ref. to Page for Applicable Toolholders :Continuous-Light Interruption / 1st Choice M Stainless Steel Q :Continuous-Light Interruption / 2nd Choice K Cast Iron Q Applicable Inserts (TKF16) ●:Continuous / 1st Choice ○:Continuous / 2nd Choice N Non-ferrous Metals Q Dimension (mm) Angle MEGACOAT MEGACOAT PVD Coated DLC Coated Carbide Insert Description NANO Carbide Carbide W φD rε T H φd θ PR1425 PR1535 PR1225 PR1025 PDL025 KW10 Handed Insert shows Right-hand max R L R L R L R L R L R L ±0.03 φd W rε T TKF16& 150-S-16DR 1.5 ●●●● ●● ●● ●● ●● rε θ φDmax 16 0.05 4 9.5 5 16° H 200-S-16DR 2.0 ●●●● ●● ●● ●● ●● Right lead angle ±0.03 rε θ φd W T TKF16& 150-S 1.5 ●●●● ●● ●● ●● ●● rε φDmax 16 0.05 4 9.5 5 0° H 200-S 2.0 ●●●● ●● ●● ●● ●● ±0.03 φd W rε T TKF16& 150-T-16DR 1.5 ●●●● ●● rε θ φDmax 16 0.08 4 9.5 5 16° H H 200-T-16DR 2.0 ●●●● ●● Right lead angle / Tough Edge H8 ±0.03 rε θ φd W T TKF16& 150-T 1.5 ●●●● ●● rε φDmax 16 0.08 4 9.5 5 0° Cut-off H 200-T 2.0 ●●●● ●● Tough Edge ±0.03 φd W rε T TKF16& 150-NB-20DR 1.5 ●●●● ● ● ● ● rε θ φDmax 16 0 4 9.5 5 20° H 200-NB-20DR 2.0 ●●●● ● ● ● ● Right lead angle Without Chipbreaker ±0.03 rε θ φd W T TKF16& 150-NB 1.5 ●●●● ● ● ● ● rε φDmax 16 0 4 9.5 5 0° H 200-NB 2.0 ●●●● ● ● ● ● Without Chipbreaker · Lead angle shows the angle when installed in toolholder. · As Fig.1 of H8 shows, the cut-off diameter of the insert is indicated when the top of the cut-off edge progresses 1mm from the center. Descriptions of Chipbreaker Edge Shape Chipbreaker S-Chipbreaker T-Chipbreaker NB (Without Chipbreaker) (Tough Edge) Edge Shape α Description α Description α Description 15° TKF12··-S α 20° TKF16··-S TKF··-T TKF··-NB TKF16··-S-16DR 12° TKF··-T-16DR 0° TKF··-NB-20DR 25° TKF12··-S-16DR N : Std. Item Inserts are sold in 10 piece boxes. H7