Основной каталог Kyocera 2016-2017 - страница 443

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

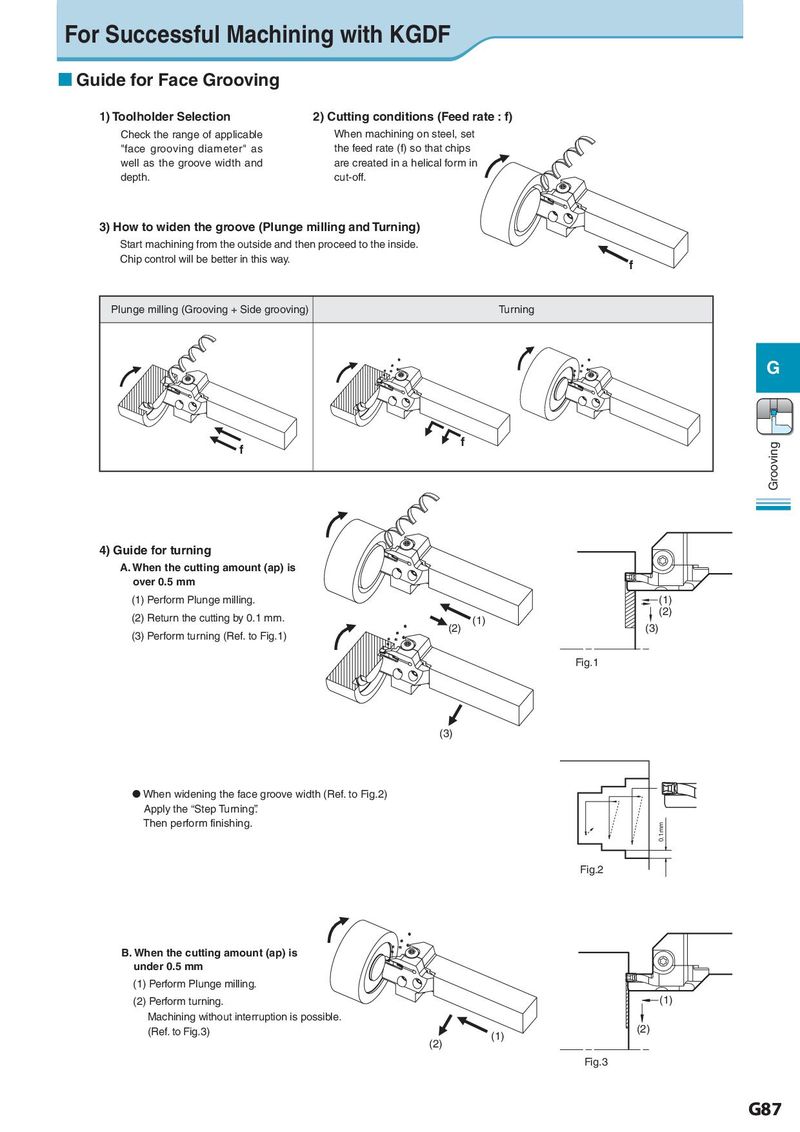

FFoarcSeuGccroesosvfiunlgMTaocohlinhionlgdewristh(分K割G) DF Guide for Face Grooving 1) Toolholder Selection 2) Cutting conditions (Feed rate : f) When machining on s図tee2l, set Check the range of applicable "face grooving diameter" as the feed rate (f) so that chips well as the groove width and are created in a helical form in depth. cut-off. 3) How to widen the groove (Plunge milling and Turning) Start machining from the outside and then proceed to the inside. Chip control will be better in this way. f Plunge milling (Grooving + Side grooving) Turning 図3 図3 G f f Grooving 図2 4) Guide for turning A. When the cutting amount (ap) is over 0.5 mm 図3 (1) Perform Plunge milling. (1) (2) Return the cutting by 0.1 mm. (1) (2) (3) Perform turning (Ref. to Fig.1) (2) (3) Fig.1 (3) When widening the face groove width (Ref. to Fig.2) Apply the “Step Turning”. Then perform finishing. 0.1mm Fig.2 図3 B. When the cutting amount (ap) is under 0.5 mm (1) Perform Plunge milling. (2) Perform turning. (1) Machining without interruption is possible. (Ref. to Fig.3) (1) (2) (2) Fig.3 G87