Основной каталог Kyocera 2016-2017 - страница 442

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

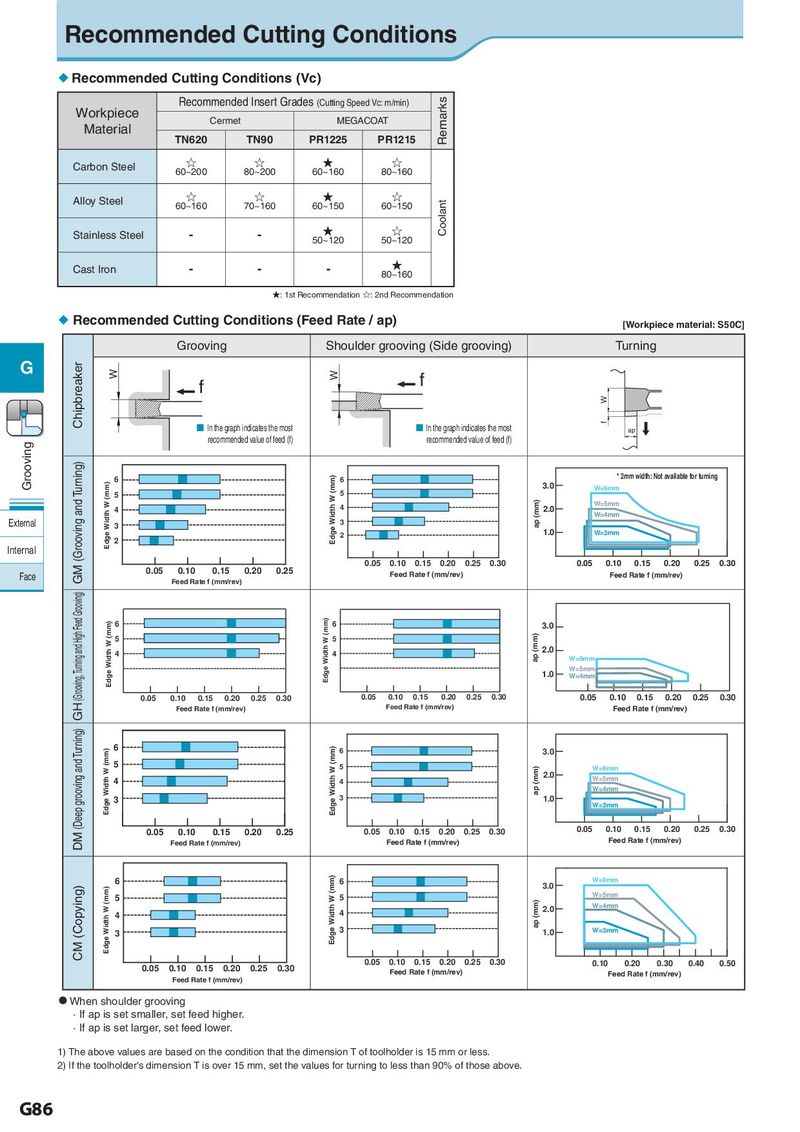

RFaeceomGmroeonvdinegd TCouotlthinogldCeorsn(d分i割t)ions Recommended Cutting Conditions (Vc) Workpiece Recommended Insert Grades (Cutting Speed Vc: m/min) Remarks Material Cermet MEGACOAT TN620 TN90 PR1225 PR1215 Carbon Steel ☆ ☆ ★ ☆ 60~200 80~200 60~160 80~160 Alloy Steel ☆ ☆ ★ ☆ Coolant 60~160 70~160 60~150 60~150 Stainless Steel - - ★ ☆ 50~120 50~120 Cast Iron - - - ★ 80~160 ★: 1st Recommendation ☆: 2nd Recommendation Recommended Cutting Conditions (Feed Rate / ap) [Workpiece material: S50C] Grooving Shoulder grooving (Side grooving) Turning G Chipbreaker W W f f W f In the graph indicates the most In the graph indicates the most ap Grooving recommended value of feed (f) recommended value of feed (f) (Grooving and Turning) 6 (mm) 6 * 2mm width: Not available for turning Edge Width W (mm) 5 3.0 W=6mm 5 Edge Width W ap (mm) 4 4 2.0 W=5mm W=4mm External 3 3 2 1.0 W=3mm 2 Internal GM 0.05 0.10 0.15 0.20 0.25 0.05 0.10 0.15 0.20 0.25 0.30 0.05 0.10 0.15 0.20 0.25 0.30 Face Feed Rate f (mm/rev) Feed Rate f (mm/rev) Feed Rate f (mm/rev) GH (Grooving, Turning and High Feed Grooving) Edge Width W (mm) 6 Width W (mm) 6 3.0 5 5 ap (mm) 4 4 2.0 W=6mm Edge 1.0 W=5mm W=4mm 0.05 0.10 0.15 0.20 0.25 0.30 0.05 0.10 0.15 0.20 0.25 0.30 0.05 0.10 0.15 0.20 0.25 0.30 Feed Rate f (mm/rev) Feed Rate f (mm/rev) Feed Rate f (mm/rev) DM (Deep grooving and Turning) Edge Width W (mm) 6 (mm) 6 3.0 5 Width W 5 ap (mm) W=6mm 4 4 2.0 W=5mm W=4mm 3 Edge 3 1.0 W=3mm 0.05 0.10 0.15 0.20 0.25 0.05 0.10 0.15 0.20 0.25 0.30 0.05 0.10 0.15 0.20 0.25 0.30 Feed Rate f (mm/rev) Feed Rate f (mm/rev) Feed Rate f (mm/rev) 6 (mm) 6 3.0 W=6mm CM (Copying) Edge Width W (mm) 5 Edge Width W 5 W=5mm 4 ap (mm) 2.0 W=4mm 4 3 3 1.0 W=3mm 0.05 0.10 0.15 0.20 0.25 0.30 0.05 0.10 0.15 0.20 0.25 0.30 0.10 0.20 0.30 0.40 0.50 Feed Rate f (mm/rev) Feed Rate f (mm/rev) Feed Rate f (mm/rev) When shoulder grooving · If ap is set smaller, set feed higher. · If ap is set larger, set feed lower. 1) The above values are based on the condition that the dimension T of toolholder is 15 mm or less. 2) If the toolholder's dimension T is over 15 mm, set the values for turning to less than 90% of those above. G86