Основной каталог Kyocera 2016-2017 - страница 418

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

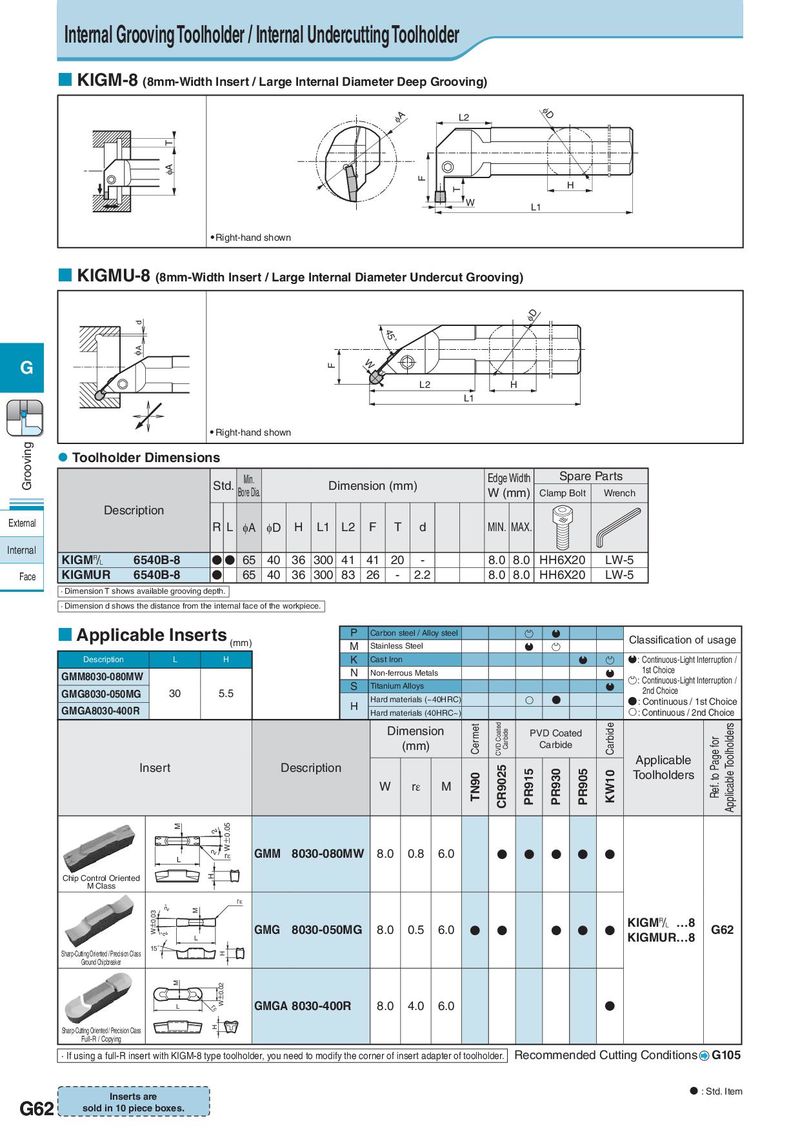

Internal Grooving Toolholder / Internal Undercutting Toolholder KIGM-8 (8mm-Width Insert / Large Internal Diameter Deep Grooving) IA L2 ID T IA F T H W L1 Right-hand shown KIGMU-8 (8mm-Width Insert / Large Internal Diameter Undercut Grooving) d ID IA 45° G F W L2 H L1 Right-hand shown Grooving Toolholder Dimensions Std. Min. Dimension (mm) Edge Width Spare Parts Bore Dia. W (mm) Clamp Bolt Wrench Description External RL φA φD H L1 L2 F T d MIN. MAX. Internal KIGM& 6540B-8 65 40 36 300 41 41 20 - 8.0 8.0 HH6X20 LW-5 ●● Face KIGMUR 6540B-8 ● 65 40 36 300 83 26 - 2.2 8.0 8.0 HH6X20 LW-5 · Dimension T shows available grooving depth. · Dimension d shows the distance from the internal face of the workpiece. Applicable Inserts (mm) P Carbon steel / Alloy steel Classification of usage M Stainless Steel Description L H K Cast Iron : Continuous-Light Interruption / GMM8030-080MW N Non-ferrous Metals 1st Choice S Titanium Alloys : Continuous-Light Interruption / GMG8030-050MG 30 5.5 2nd Choice H Hard materials (~40HRC) ● ● : Continuous / 1st Choice GMGA8030-400R Hard materials (40HRC~) : Continuous / 2nd Choice Dimension Cermet CVD Coated Carbide PVD Coated Carbide Ref. to Page for Applicable Toolholders (mm) Carbide Insert Description CR9025 Applicable TN90 PR915 PR930 PR905 KW10 Toolholders W rε M M 2 W±0.05 2 rH GMM 8030-080MW 8.0 0.8 6.0 ● ● ● ● ● L Chip Control Oriented H M Class 2゜ rH W±0.03 M 2゜ GMG 8030-050MG 8.0 0.5 6.0 ● ● ● ● ● KIGM&U…8 G62 L KIGMUR…8 Sharp-Cutting Oriented / Precision Class 15° H Ground Chipbreaker M W±0.02 L rH GMGA 8030-400R 8.0 4.0 6.0 ● Sharp-Cutting Oriented / Precision Class H Full-R / Copying · If using a full-R insert with KIGM-8 type toolholder, you need to modify the corner of insert adapter of toolholder. Recommended Cutting Conditions G105 Inserts are : Std. Item G62 sold in 10 piece boxes.