Основной каталог Kyocera 2016-2017 - страница 384

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

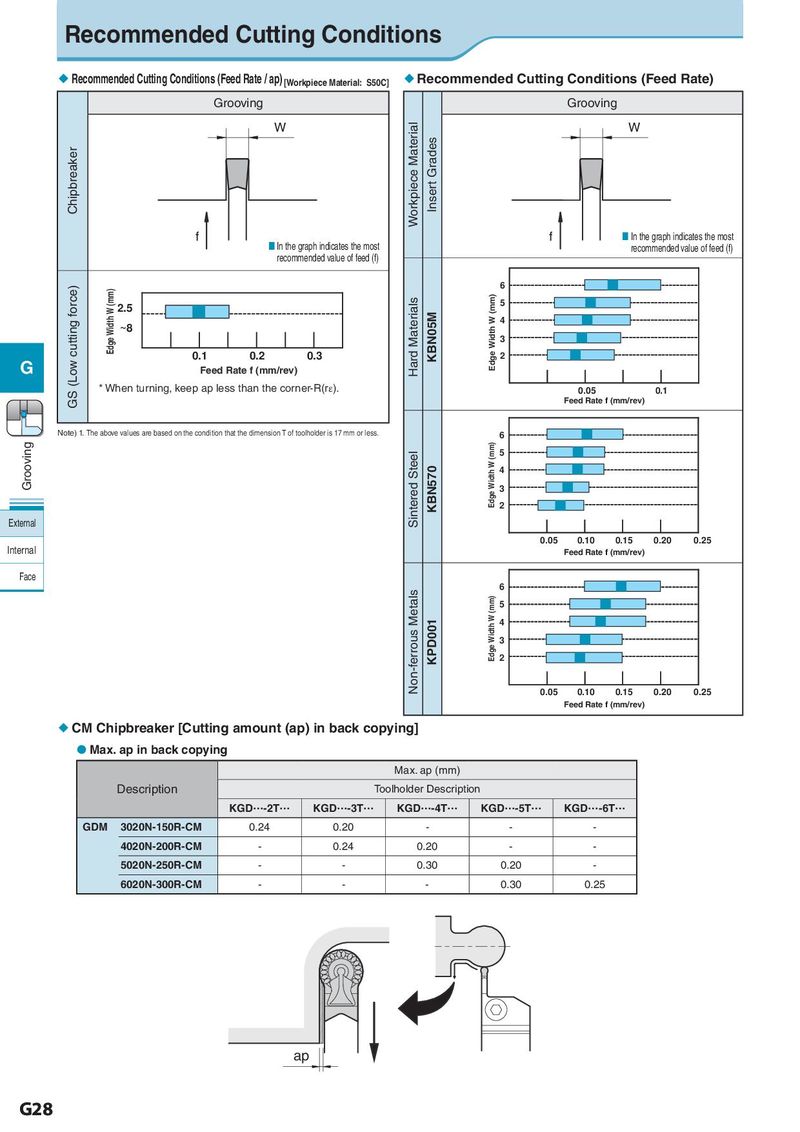

Recommended Cutting Conditions Recommended Cutting Conditions (Feed Rate / ap) [Workpiece Material: S50C] Recommended Cutting Conditions (Feed Rate) Grooving Grooving W Workpiece Material W Chipbreaker Insert Grades f In the graph indicates the most f In the graph indicates the most recommended value of feed (f) recommended value of feed (f) (Low cutting force) Edge Width W (mm) 6 6 2.5 Hard Materials Edge Width W (mm) 5Edge Width W (mm) 5 ~8 KBN05M 4 4 3 3 G 0.1 0.2 0.3 2 2 Feed Rate f (mm/rev) GS *When turning, keep ap less than the corner-R(rε). 0.005.05 0.10.1 FeeFdeeRdatReafte(mf m(m/rmev/r)ev) Note) 1. The above values are based on the condition that the dimension T of toolholder is 17 mm or less. 6 6 Grooving Sintered Steel Edge Width W (mm) 5Edge Width W (mm) 5 KBN570 4 4 3 3 2 2 External Internal 0.05 0.10.05 0.15 0.20 .1 0.25 FFeeeedd RRaattee ff ((mmmm//rreevv)) Face Non-ferrous Metals 6 6 Edge Width W (mm) 5Edge Width W (mm) 5 KPD001 4 4 3 3 2 2 0.05 0.100.05 0.15 0.200.1 0.25 FeFeedeRdaRteatfe(mf (mm/mre/vre) v) CM Chipbreaker [Cutting amount (ap) in back copying] Max. ap in back copying Max. ap (mm) Description Toolholder Description KGD…-2T… KGD…-3T… KGD…-4T… KGD…-5T… KGD…-6T… GDM 3020N-150R-CM 0.24 0.20 - - - 4020N-200R-CM - 0.24 0.20 - - 5020N-250R-CM - - 0.30 0.20 - 6020N-300R-CM - - - 0.30 0.25 ap G28