Основной каталог Kyocera 2016-2017 - страница 385

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

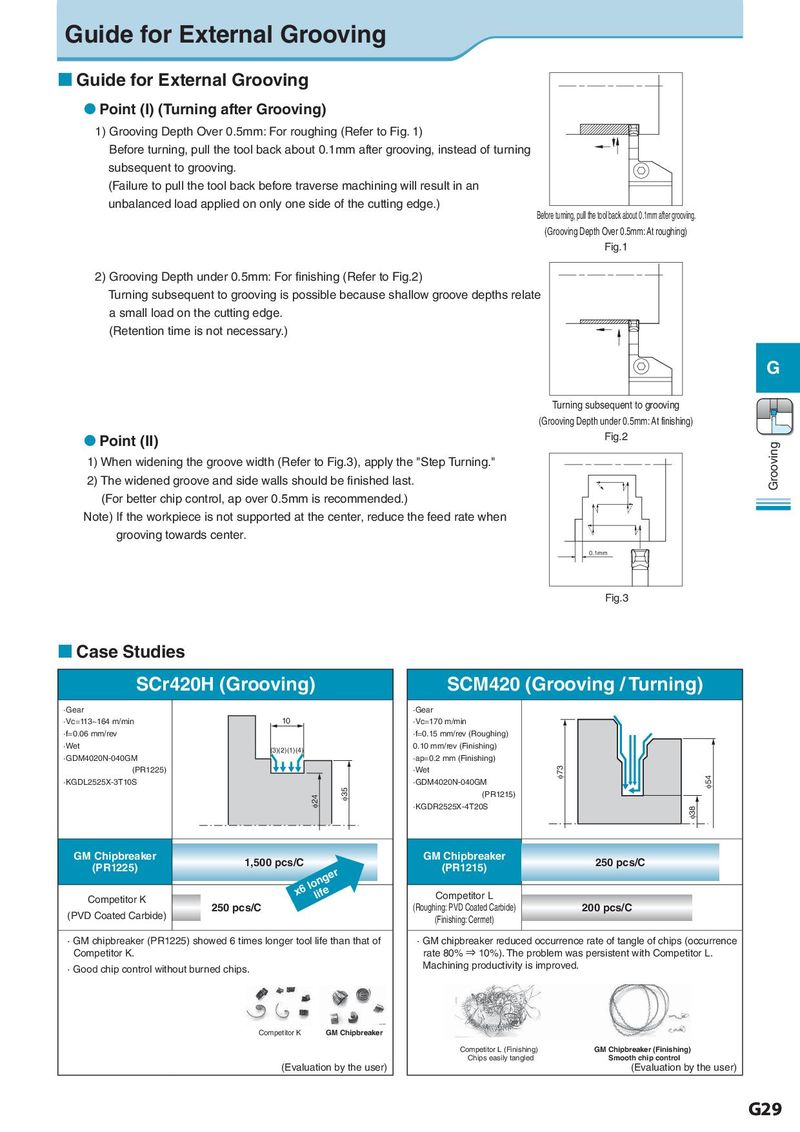

Guide for External Grooving Guide for External Grooving Point (I) (Turning after Grooving) 1)Grooving Depth Over 0.5mm: For roughing (Refer to Fig. 1) Before turning, pull the tool back about 0.1mm after grooving, instead of turning subsequent to grooving. (Failure to pull the tool back before traverse machining will result in an unbalanced load applied on only one side of the cutting edge.) Before turning, pull the tool back about 0.1mm after grooving. (Grooving Depth Over 0.5mm: At roughing) Fig.1 2)Grooving Depth under 0.5mm: For finishing (Refer to Fig.2) Turning subsequent to grooving is possible because shallow groove depths relate a small load on the cutting edge. (Retention time is not necessary.) G Turning subsequent to grooving (Grooving Depth under 0.5mm: At finishing) Point (II) Fig.2 1)When widening the groove width (Refer to Fig.3), apply the "Step Turning." Grooving 2)The widened groove and side walls should be finished last. (For better chip control, ap over 0.5mm is recommended.) Note)If the workpiece is not supported at the center, reduce the feed rate when grooving towards center. 0.1mm Fig.3 Case Studies SCr420H (Grooving) SCM420 (Grooving / Turning) ·Gear ·Gear ·Vc=113~164 m/min 10 ·Vc=170 m/min ·f=0.06 mm/rev ·f=0.15 mm/rev (Roughing) ·Wet (3)(2)(1)(4) 0.10 mm/rev (Finishing) ·GDM4020N-040GM ·ap=0.2 mm (Finishing) (PR1225) ·Wet φ73 ·KGDL2525X-3T10S ·GDM4020N-040GM φ54 φ24 φ35 (PR1215) ·KGDR2525X-4T20S φ38 GM Chipbreaker 1,500 pcs/C GM Chipbreaker 250 pcs/C (PR1225) x6 lolnifgeer (PR1215) Competitor K Competitor L (PVD Coated Carbide) 250 pcs/C (Roughing: PVD Coated Carbide) 200 pcs/C (Finishing: Cermet) · GM chipbreaker (PR1225) showed 6 times longer tool life than that of · GM chipbreaker reduced occurrence rate of tangle of chips (occurrence Competitor K. rate 80% ⇒ 10%). The problem was persistent with Competitor L. · Good chip control without burned chips. Machining productivity is improved. Competitor K GM Chipbreaker Competitor L (Finishing) GM Chipbreaker (Finishing) Chips easily tangled Smooth chip control (Evaluation by the user) (Evaluation by the user) G29