Основной каталог Kyocera 2016-2017 - страница 383

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

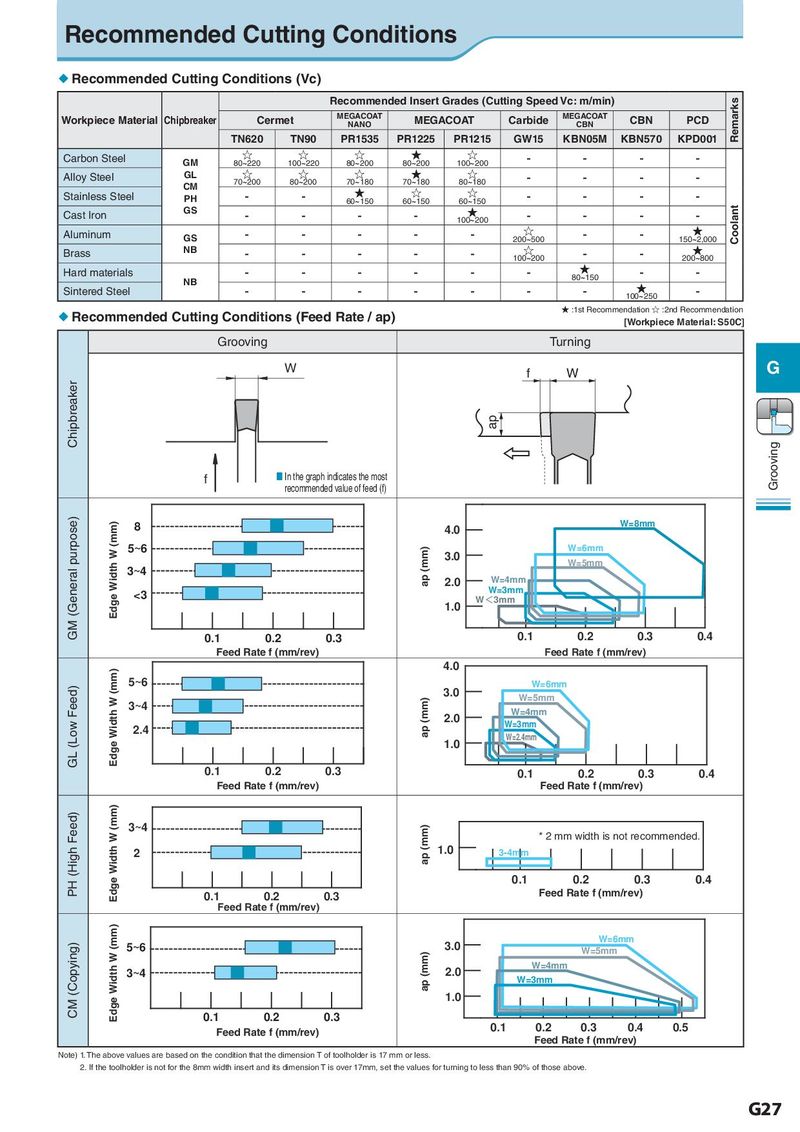

Recommended Cutting Conditions Recommended Cutting Conditions (Vc) Recommended Insert Grades (Cutting Speed Vc: m/min) Remarks Workpiece Material Chipbreaker Cermet MEGACOAT MEGACOAT Carbide MEGACOAT CBN PCD NANO CBN TN620 TN90 PR1535 PR1225 PR1215 GW15 KBN05M KBN570 KPD001 Carbon Steel GM ☆ ☆ ☆ ★ ☆ - - - - 80~220 100~220 80~200 80~200 100~200 Alloy Steel GL ☆ ☆ ☆ ★ ☆ - - - - 70~200 80~200 70~180 70~180 80~180 CM - - ★ ☆ ☆ - - - - Stainless Steel PH 60~150 60~150 60~150 Cast Iron GS - - - - ★ - - - - Coolant 100~200 Aluminum GS - - - - - ☆ - - ★ 200~500 150~2,000 Brass NB - - - - - ☆ - - ★ 100~200 200~800 Hard materials - - - - - - ★ - - 80~150 NB - - - - - - - ★ - Sintered Steel 100~250 Recommended Cutting Conditions (Feed Rate / ap) ★ :1st Recommendation ☆ :2nd Recommendation [Workpiece Material: S50C] Grooving Turning W f W G Chipbreaker ap f In the graph indicates the most Grooving recommended value of feed (f) GM (General purpose) EEddggee WWiiddtthh WW ((mmmm)) 8 4.0 W=8mm 55~~66 ap (mm) 3.0 W=6mm 33~~44 W=5mm 2.0 W=4mm <23.4 W=3mm 1.0 W<3mm 00..11 00..22 00..33 0.1 0.2 0.3 0.4 FFeeeeddRRaatteeff((mmmm//rreevv)) Feed Rate f (mm/rev) EdEgdegeWidWtihdthW (Wm(mm)m) 4.0 W=8mm GL (Low Feed) 5~6 4.0 W=6mm 5~6 aapp( (mmm)m) 3.0 W=5mm W=6mm 3~4 3.0 W=4mm W=5mm 3~4 2.0 WW==3W4Wmm==m23m.4mmmm 2.4 2.4 2.0 1.0 W<3mm 1.0 0.1 0.2 0.3 0.1 0.2 0.3 0.4 0.F1eed Rate 0f .(2mm/rev) 0.3 0.1 Feed Ra0te.2f (mm/rev0).3 0.4 Feed Rate f (mm/rev) Feed Rate f (mmW/r=e8vm) m EdgEedgeWiWditdthhWW ((mmm)m) 4.0 PH (High Feed) 35~~46 aapp((mmmm)) 3.0 W=6mm * 2 mmWw=5idmthmis not recommended. 1.0 32~4 2.0 W3=-44mmmm 2.4 W=3mm 1.0 W<3mm0.1 0.2 0.3 0.4 0.1 0.2 0.3 Feed Rate f (mm/rev) Feed Rate f (mm/rev) 0.1 0.2 0.3 0.4 EEddggeeWiWidtdthhWW( (mmm)m) 0.1 0.2 0.3 Feed Rate f (mm/rev) 4.0 Feed Rate f (mmW/r=e8vm) m W=6mm CM (Copying) 55~~66 3.0 aapp( (mmm)m) W=W6m=m5mm 3.0 33~~44 2.0 W=4mmW=5mm 2.0 W=4mWm=3mm 2.4 1.0 W=3mm 1.0 W<3mm 0.1 0.2 0.3 0.1 0.2 0.3 0.4 0.5 0.F1eed Rate 0f .(2mm/rev) 0.3 0.1Feed Rat0e.f2(mm/rev)0.3 0.4 Note)1. The above values are based on the coFnedeitidonRthaattethef (dmimmen/srioenvT) of toolholder is 17 mm or less. Feed Rate f (mm/rev) 2. If the toolholder is not for the 8mm width insert and its dimension T is over 17mm, set the values for turning to less than 90% of those above. G27