Основной каталог Kyocera 2016-2017 - страница 38

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

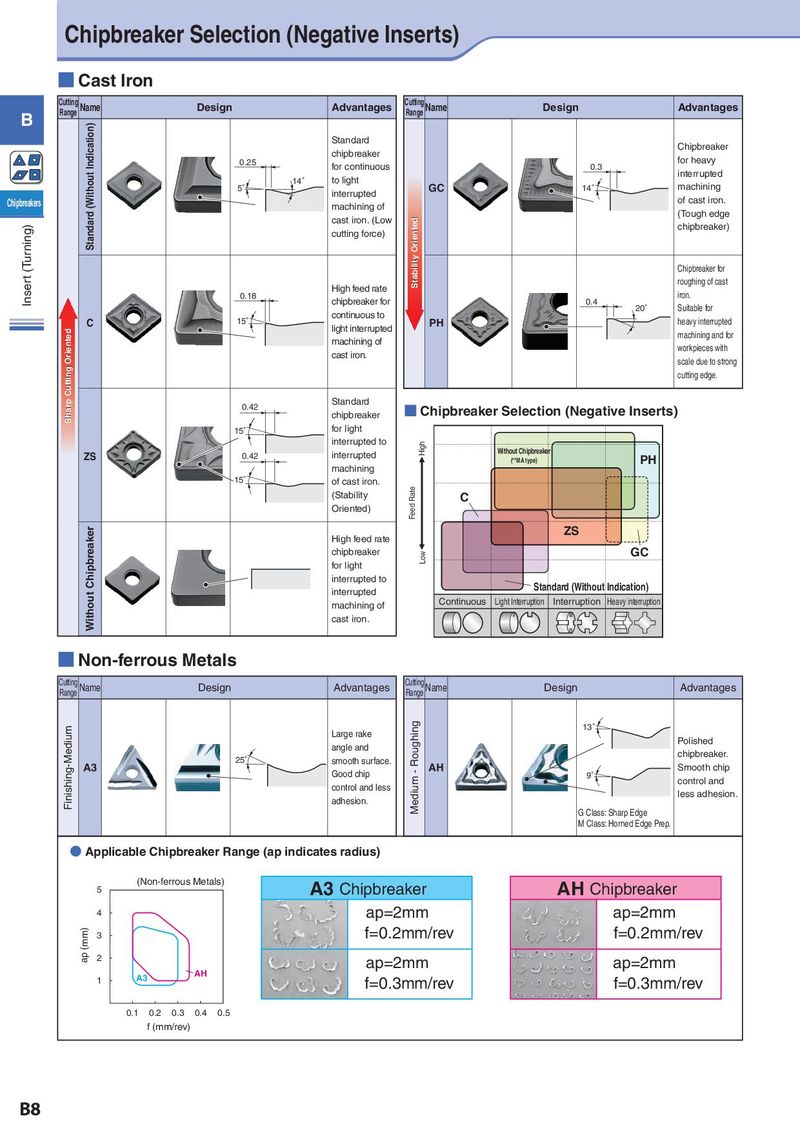

Chipbreaker Selection (Negative Inserts) ■ Cast Iron Cutting Name Design Advantages Cutting Name Design Advantages B Range Range Indication) Standard Chipbreaker chipbreaker for heavy 0.25 for continuous 0.3 Standard (Without 14° to light interrupted 5° interrupted GC 14° machining Chipbreakers machining of of cast iron. Sharp Cutting Orientedcast iron. (LowStability Oriented (Tough edge Insert (Turning) cutting force) chipbreaker) Chipbreaker for High feed rate roughing of cast 0.18 chipbreaker for 0.4 iron. continuous to 20° Suitable for C 15° light interrupted PH heavy interrupted Sharp Cutting Oriented Stability Oriented machining of machining and for cast iron. workpieces with scale due to strong cutting edge. 0.42 Standard ■ Chipbreaker Selection (Negative Inserts) chipbreaker 15° for light interrupted to High ZS 0.42 interrupted Without Chipbreaker (**MA type) PH machining 15° of cast iron. (Stability Feed Rate C Oriented) Chipbreaker High feed rate ZS chipbreaker Low GC for light interrupted to Standard (Without Indication) Without interrupted machining of Continuous Light Interruption Interruption Heavy interruption cast iron. ■ Non-ferrous Metals Cutting Name Design Advantages Cutting Name Design Advantages Range Range Finishing-Medium Large rake Medium - Roughing 13° angle and Polished 25° smooth surface. chipbreaker. A3 Good chip AH 9° Smooth chip control and less control and adhesion. less adhesion. G Class: Sharp Edge M Class: Horned Edge Prep. ● Applicable Chipbreaker Range (ap indicates radius) 5 (Non-ferrous Metals) A3 Chipbreaker AH Chipbreaker 4 da=p2=m2mm da=p3=m2mm ap (mm) 3 f=0.2mm/rev f=0.2mm/rev 2 da=p2=m2mm da=p3=m2mm 1 A3 AH f=0.3mm/rev f=0.3mm/rev 0.1 0.2 0.3 0.4 0.5 f (mm/rev) B8