Основной каталог Kyocera 2016-2017 - страница 27

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

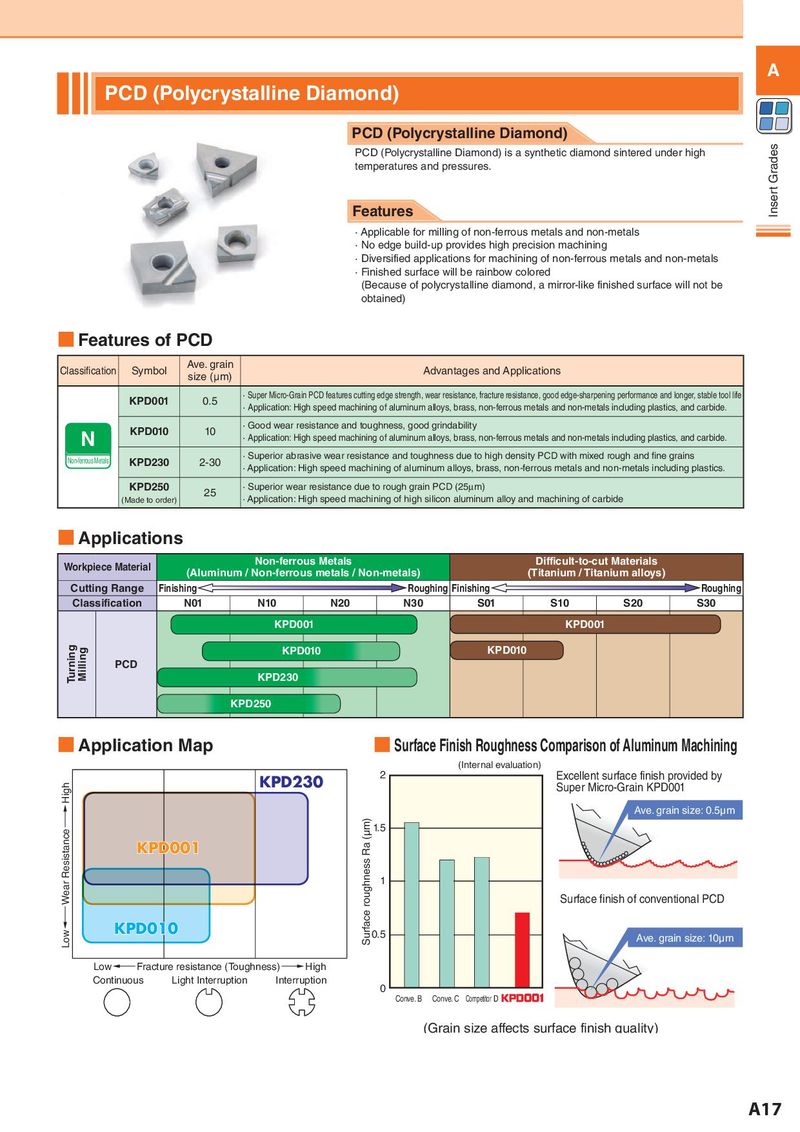

A PCD (Polycrystalline Diamond) PCD (Polycrystalline Diamond) PCD (Polycrystalline Diamond) is a synthetic diamond sintered under high Insert Grades temperatures and pressures. Features · Applicable for milling of non-ferrous metals and non-metals · No edge build-up provides high precision machining · Diversified applications for machining of non-ferrous metals and non-metals · Finished surface will be rainbow colored (Because of polycrystalline diamond, a mirror-like finished surface will not be obtained) ■ Features of PCD Classification Symbol Ave. grain Advantages and Applications size (μm) KPD001 0.5 · Super Micro-Grain PCD features cutting edge strength, wear resistance, fracture resistance, good edge-sharpening performance and longer, stable tool life · Application: High speed machining of aluminum alloys, brass, non-ferrous metals and non-metals including plastics, and carbide. KPD010 10 · Good wear resistance and toughness, good grindability N · Application: High speed machining of aluminum alloys, brass, non-ferrous metals and non-metals including plastics, and carbide. Non-ferrous Metals KPD230 2-30 · Superior abrasive wear resistance and toughness due to high density PCD with mixed rough and fine grains · Application: High speed machining of aluminum alloys, brass, non-ferrous metals and non-metals including plastics. KPD250 25 · Superior wear resistance due to rough grain PCD (25μm) (Made to order) · Application: High speed machining of high silicon aluminum alloy and machining of carbide ■ Applications Workpiece Material Non-ferrous Metals Difficult-to-cut Materials (Aluminum / Non-ferrous metals / Non-metals) (Titanium / Titanium alloys) Cutting Range Finishing Roughing Finishing Roughing Classification N01 N10 N20 N30 S01 S10 S20 S30 KPD001 KPD001 Turning Milling KPD010 KPD010 PCD KPD230 KPD250 ■ Application Map ■ Surface Finish Roughness Comparison of Aluminum Machining (Internal evaluation) KPD230 2 Excellent surface finish provided by High Super Micro-Grain KPD001 Ave. grain size: 0.5µm Wear Resistance→ roughness Ra (μm) 1.5 KPD001 1 Surface finish of conventional PCD Low ← KPD010 Surface 0.5 Ave. grain size: 10µm Low←Fracture resistance (Toughness)→High Continuous Light Interruption Interruption 0 Conve. B Conve. C Competitor D (Grain size affects surface finish quality) A17