Основной каталог Kyocera 2016-2017 - страница 28

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

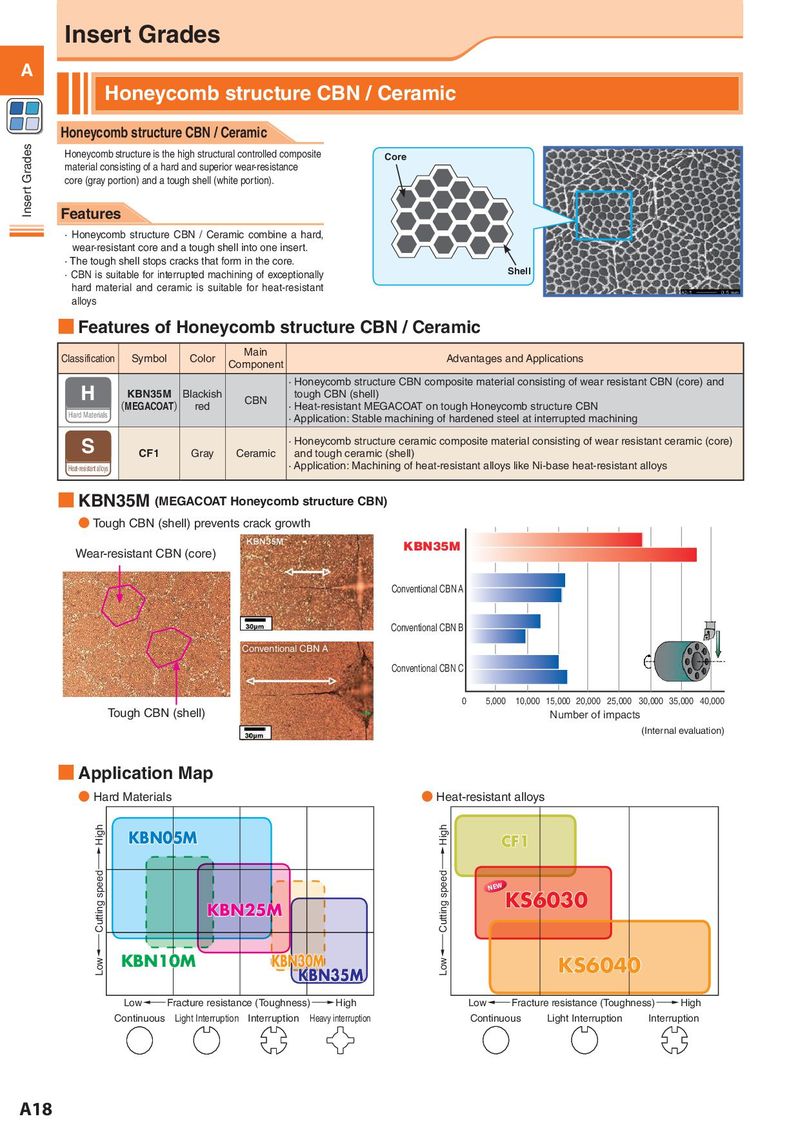

Insert Grades A Honeycomb structure CBN / Ceramic Honeycomb structure CBN / Ceramic Insert Grades Honeycomb structure is the high structural controlled composite Core material consisting of a hard and superior wear-resistance core (gray portion) and a tough shell (white portion). Features · Honeycomb structure CBN / Ceramic combine a hard, wear-resistant core and a tough shell into one insert. · The tough shell stops cracks that form in the core. · CBN is suitable for interrupted machining of exceptionally Shell hard material and ceramic is suitable for heat-resistant alloys ■ Features of Honeycomb structure CBN / Ceramic Classification Symbol Color Main Advantages and Applications Component H · Honeycomb structure CBN composite material consisting of wear resistant CBN (core) and KBN35M Blackish CBN tough CBN (shell) Hard Materials (MEGACOAT) red · Heat-resistant MEGACOAT on tough Honeycomb structure CBN · Application: Stable machining of hardened steel at interrupted machining S · Honeycomb structure ceramic composite material consisting of wear resistant ceramic (core) CF1 Gray Ceramic and tough ceramic (shell) Heat-resistant alloys · Application: Machining of heat-resistant alloys like Ni-base heat-resistant alloys ■ KBN35M (MEGACOAT Honeycomb structure CBN) ● Tough CBN (shell) prevents crack growth Wear-resistant CBN (core) KBN35M Conventional CBN A Conventional CBN B Conventional CBN A Conventional CBN C 0 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 Tough CBN (shell) Number of impacts (Internal evaluation) ■ Application Map ● Hard Materials ● Heat-resistant alloys High KBN05M High CF1 speed→ speed→ NEW Cutting KBN25M Cutting KS6030 Low ← KBN10M KBN30M Low ← KS6040 KBN35M Low←Fracture resistance (Toughness)→High Low←Fracture resistance (Toughness)→High Continuous Light Interruption Interruption Heavy interruption Continuous Light Interruption Interruption A18