Основной каталог Kyocera 2016-2017 - страница 26

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

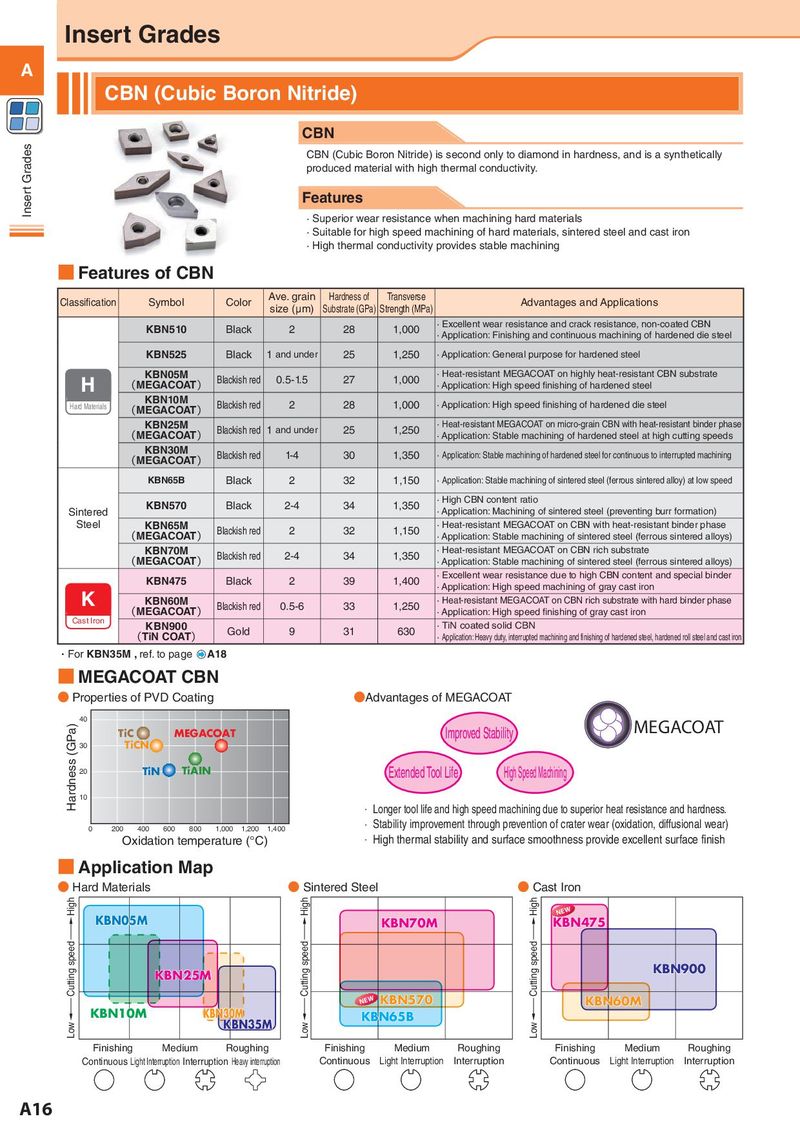

Insert Grades A CBN (Cubic Boron Nitride) CBN Insert Grades CBN (Cubic Boron Nitride) is second only to diamond in hardness, and is a synthetically produced material with high thermal conductivity. Features · Superior wear resistance when machining hard materials · Suitable for high speed machining of hard materials, sintered steel and cast iron · High thermal conductivity provides stable machining ■ Features of CBN Classification Symbol Color Ave. grain Hardness of Transverse Advantages and Applications size (μm) Substrate (GPa) Strength (MPa) KBN510 Black 2 28 1,000 · Excellent wear resistance and crack resistance, non-coated CBN · Application: Finishing and continuous machining of hardened die steel KBN525 Black 1 and under 25 1,250 · Application: General purpose for hardened steel H KBN05M Blackish red 0.5-1.5 27 1,000 · Heat-resistant MEGACOAT on highly heat-resistant CBN substrate (MEGACOAT) · Application: High speed finishing of hardened steel Hard Materials KBN10M Blackish red 2 28 1,000 · Application: High speed finishing of hardened die steel (MEGACOAT) KBN25M Blackish red 1 and under 25 1,250 · Heat-resistant MEGACOAT on micro-grain CBN with heat-resistant binder phase (MEGACOAT) · Application: Stable machining of hardened steel at high cutting speeds KBN30M Blackish red 1-4 30 1,350 · Application: Stable machining of hardened steel for continuous to interrupted machining (MEGACOAT) KBN65B Black 2 32 1,150 · Application: Stable machining of sintered steel (ferrous sintered alloy) at low speed KBN570 Black 2-4 34 1,350 · High CBN content ratio Sintered · Application: Machining of sintered steel (preventing burr formation) Steel KBN65M Blackish red 2 32 1,150 · Heat-resistant MEGACOAT on CBN with heat-resistant binder phase (MEGACOAT) · Application: Stable machining of sintered steel (ferrous sintered alloys) KBN70M Blackish red 2-4 34 1,350 · Heat-resistant MEGACOAT on CBN rich substrate (MEGACOAT) · Application: Stable machining of sintered steel (ferrous sintered alloys) KBN475 Black 2 39 1,400 · Excellent wear resistance due to high CBN content and special binder K · Application: High speed machining of gray cast iron KBN60M Blackish red 0.5-6 33 1,250 · Heat-resistant MEGACOAT on CBN rich substrate with hard binder phase (MEGACOAT) · Application: High speed finishing of gray cast iron Cast Iron KBN900 · TiN coated solid CBN (TiN COAT) Gold 9 31 630 · Application: Heavy duty, interrupted machining and finishing of hardened steel, hardened roll steel and cast iron ・For KBN35M , ref. to page A18 ■ MEGACOAT CBN ● Properties of PVD Coating ●Advantages of MEGACOAT 40 MEGACOAT Hardness (GPa) TiC MEGACOAT Improved Stability 30 TiCN 20 TiN TiAIN Extended Tool Life High Speed Machining 10 · Longer tool life and high speed machining due to superior heat resistance and hardness. 0 200 400 600 800 1,000 1,200 1,400 · Stability improvement through prevention of crater wear (oxidation, diffusional wear) Oxidation temperature (°C) · High thermal stability and surface smoothness provide excellent surface finish ■ Application Map ● Hard Materials ● Sintered Steel ● Cast Iron High High High NEW KBN05M KBN70M KBN475 Cutting speed→ Cutting speed→ Cutting speed→ KBN25M KBN900 NEW KBN570 KBN60M ← KBN10M KBN30M ← KBN65B ← KBN35M Low Low Low Finishing Medium Roughing Finishing Medium Roughing Finishing Medium Roughing Continuous Light Interruption Interruption Heavy interruption Continuous Light Interruption Interruption Continuous Light Interruption Interruption A16