Основной каталог Kyocera 2016-2017 - страница 25

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

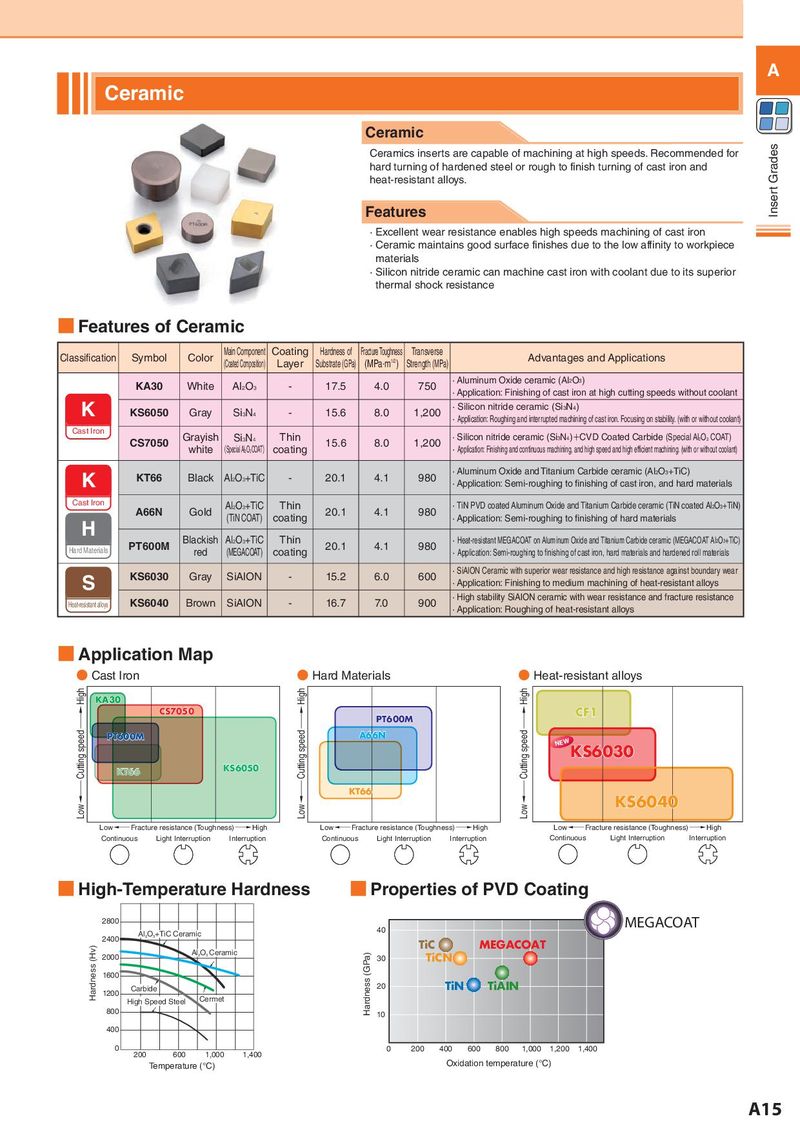

A Ceramic Ceramic Ceramics inserts are capable of machining at high speeds. Recommended for Insert Grades hard turning of hardened steel or rough to finish turning of cast iron and heat-resistant alloys. Features · Excellent wear resistance enables high speeds machining of cast iron · Ceramic maintains good surface finishes due to the low affinity to workpiece materials · Silicon nitride ceramic can machine cast iron with coolant due to its superior thermal shock resistance ■ Features of Ceramic Classification Symbol Color Main Component Coating Hardness of Fracture Toughness Transverse Advantages and Applications (MPa.m1/2) (Coated Composition) Layer Substrate (GPa) Strength (MPa) KA30 White Al2O3 - 17.5 4.0 750 · Aluminum Oxide ceramic (Al2O3) · Application: Finishing of cast iron at high cutting speeds without coolant K KS6050 Gray Si3N4 - 15.6 8.0 1,200 · Silicon nitride ceramic (Si3N4) · Application: Roughing and interrupted machining of cast iron. Focusing on stability. (with or without coolant) Cast Iron Grayish Si3N4 Thin · Silicon nitride ceramic (Si3N4)+CVD Coated Carbide (Special Al2O3 COAT) CS7050 white (Special Al2O3 COAT) coating 15.6 8.0 1,200 · Application: Finishing and continuous machining, and high speed and high efficient machining. (with or without coolant) K KT66 Black Al2O3+TiC - 20.1 4.1 980 · Aluminum Oxide and Titanium Carbide ceramic (Al2O3+TiC) · Application: Semi-roughing to finishing of cast iron, and hard materials Cast Iron Al2O3+TiC Thin · TiN PVD coated Aluminum Oxide and Titanium Carbide ceramic (TiN coated Al2O3+TiN) A66N Gold (TiN COAT) coating 20.1 4.1 980 · Application: Semi-roughing to finishing of hard materials H Blackish Al2O3+TiC Thin · Heat-resistant MEGACOAT on Aluminum Oxide and Titanium Carbide ceramic (MEGACOAT Al2O3+TiC) Hard Materials PT600M red (MEGACOAT) coating 20.1 4.1 980 · Application: Semi-roughing to finishing of cast iron, hard materials and hardened roll materials S KS6030 Gray SiAlON - 15.2 6.0 600 · SiAlON Ceramic with superior wear resistance and high resistance against boundary wear · Application: Finishing to medium machining of heat-resistant alloys Heat-resistant alloys KS6040 Brown SiAlON - 16.7 7.0 900 · High stability SiAlON ceramic with wear resistance and fracture resistance · Application: Roughing of heat-resistant alloys ■ Application Map ● Cast Iron ● Hard Materials ● Heat-resistant alloys High KA30 High High CS7050 PT600M CF1 Cutting speed→ PT600M Cutting speed→ A66N Cutting speed→ NEW KS6030 KT66 KS6050 KT66 Low ← Low ← Low ← KS6040 Low←Fracture resistance (Toughness)→High Low←Fracture resistance (Toughness)→High Low←Fracture resistance (Toughness)→High Continuous Light Interruption Interruption Continuous Light Interruption Interruption Continuous Light Interruption Interruption ■ High-Temperature Hardness ■ Properties of PVD Coating 2800 MEGACOAT Al2O3+TiC Ceramic 40 2400 TiC MEGACOAT Hardness (Hv) 2000 Al2O3 Ceramic Hardness (GPa) 30 TiCN 1600 Carbide 20 TiN TiAIN 1200 Cermet High Speed Steel 800 10 400 0 200 600 1,000 1,400 0 200 400 600 800 1,000 1,200 1,400 Temperature (°C) Oxidation temperature (°C) A15