Основной каталог Kyocera 2016-2017 - страница 24

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

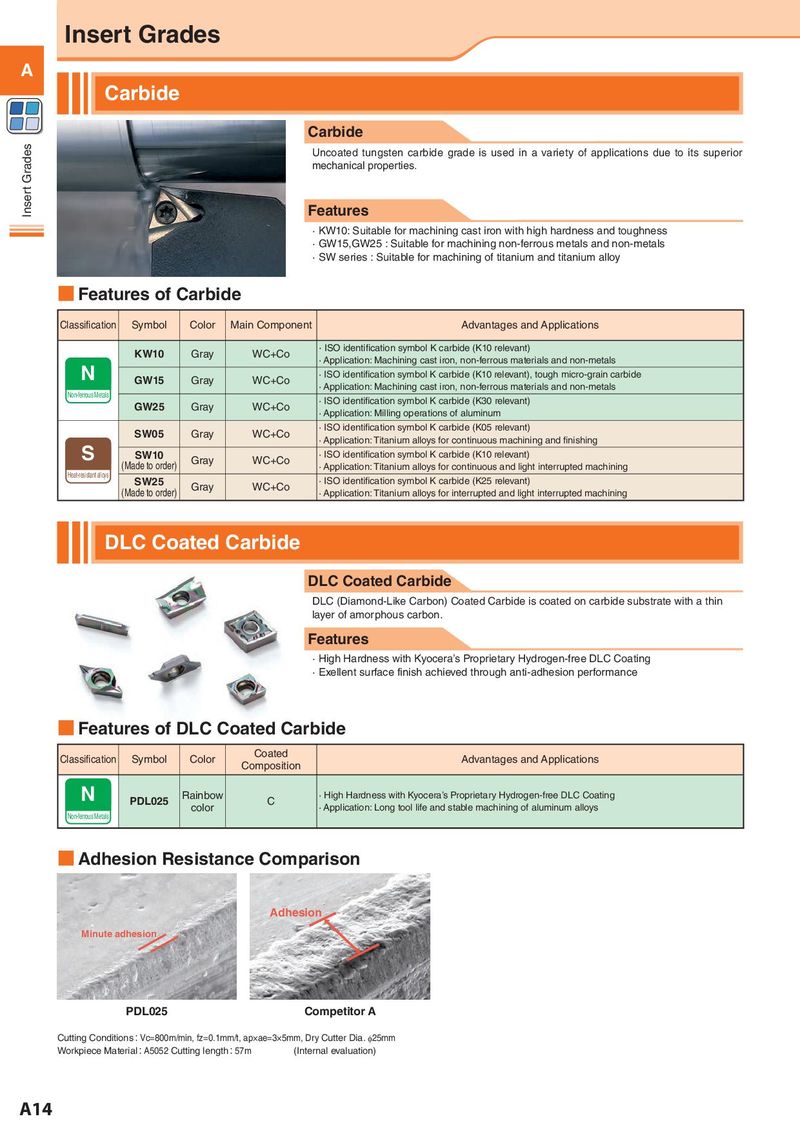

Insert Grades A Carbide Carbide Insert Grades Uncoated tungsten carbide grade is used in a variety of applications due to its superior mechanical properties. Features · KW10: Suitable for machining cast iron with high hardness and toughness · GW15,GW25 : Suitable for machining non-ferrous metals and non-metals · SW series : Suitable for machining of titanium and titanium alloy ■ Features of Carbide Classification Symbol Color Main Component Advantages and Applications KW10 Gray WC+Co · ISO identification symbol K carbide (K10 relevant) · Application: Machining cast iron, non-ferrous materials and non-metals N GW15 Gray WC+Co · ISO identification symbol K carbide (K10 relevant), tough micro-grain carbide · Application: Machining cast iron, non-ferrous materials and non-metals Non-ferrous Metals · ISO identification symbol K carbide (K30 relevant) GW25 Gray WC+Co · Application: Milling operations of aluminum SW05 Gray WC+Co · ISO identification symbol K carbide (K05 relevant) · Application: Titanium alloys for continuous machining and finishing S SW10 Gray WC+Co · ISO identification symbol K carbide (K10 relevant) (Made to order) · Application: Titanium alloys for continuous and light interrupted machining Heat-resistant alloys SW25 · ISO identification symbol K carbide (K25 relevant) (Made to order) Gray WC+Co · Application: Titanium alloys for interrupted and light interrupted machining DLC Coated Carbide DLC Coated Carbide DLC (Diamond-Like Carbon) Coated Carbide is coated on carbide substrate with a thin layer of amorphous carbon. Features · High Hardness with Kyocera’s Proprietary Hydrogen-free DLC Coating · Exellent surface finish achieved through anti-adhesion performance ■ Features of DLC Coated Carbide Classification Symbol Color Coated Advantages and Applications Composition N PDL025 Rainbow C · High Hardness with Kyocera’s Proprietary Hydrogen-free DLC Coating color · Application: Long tool life and stable machining of aluminum alloys Non-ferrous Metals ■ Adhesion Resistance Comparison Adhesion Minute adhesion PDL025 Competitor A Cutting Conditions:Vc=800m/min, fz=0.1mm/t, ap×ae=3×5mm, Dry Cutter Dia. φ25mm Workpiece Material:A5052 Cutting length:57m (Internal evaluation) A14