Основной каталог Kyocera 2016-2017 - страница 229

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

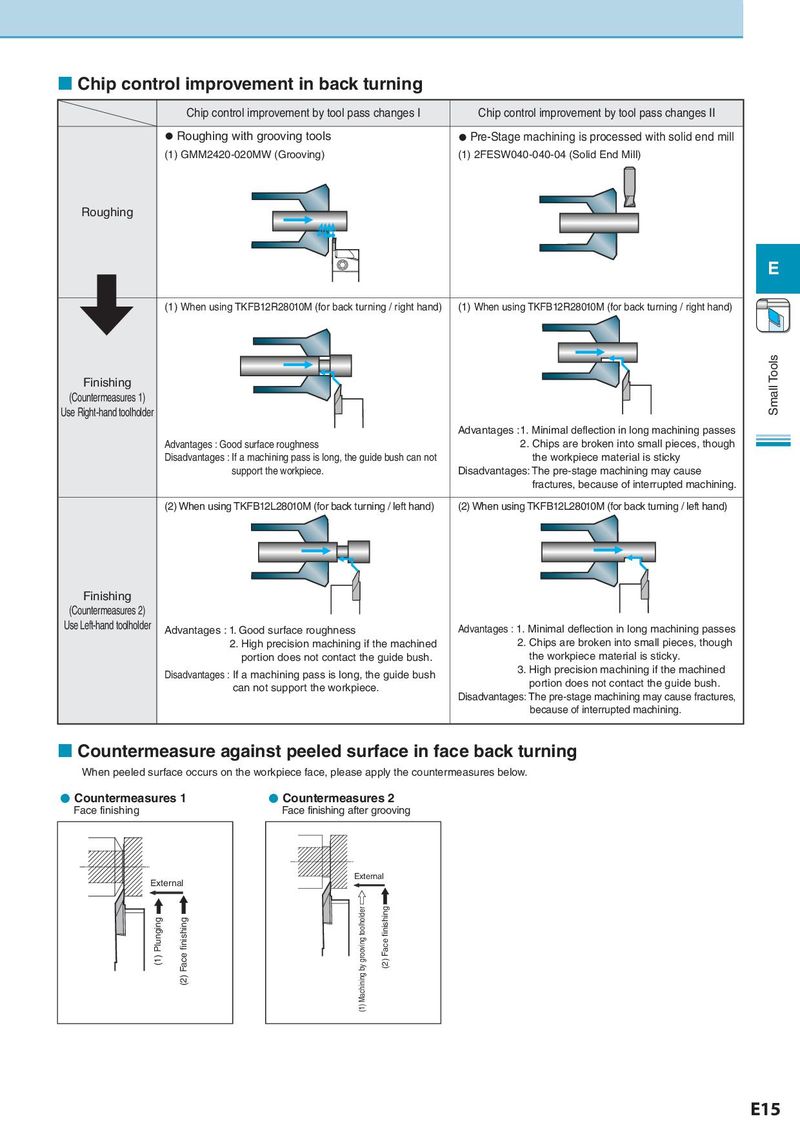

¢ Chip control improvement in back turning Chip control improvement by tool pass changes I Chip control improvement by tool pass changes II l Roughing with grooving tools l Pre-Stage machining is processed with solid end mill (1) GMM2420-020MW (Grooving) (1)2FESW040-040-04 (Solid End Mill) Roughing E (1)When using TKFB12R28010M (for back turning / right hand) (1) When using TKFB12R28010M (for back turning / right hand) Finishing Small Tools (Countermeasures 1) Use Right-hand toolholder Advantages :1. Minimal deflection in long machining passes Advantages : Good surface roughness 2.Chips are broken into small pieces, though Disadvantages :If a machining pass is long, the guide bush can not the workpiece material is sticky support the workpiece. Disadvantages:The pre-stage machining may cause fractures, because of interrupted machining. (2)When using TKFB12L28010M (for back turning / left hand) (2)When using TKFB12L28010M (for back turning / left hand) Finishing (Countermeasures 2) Use Left-hand toolholder Advantages : 1. Good surface roughness Advantages : 1. Minimal deflection in long machining passes 2.High precision machining if the machined 2.Chips are broken into small pieces, though portion does not contact the guide bush. the workpiece material is sticky. Disadvantages :If a machining pass is long, the guide bush 3.High precision machining if the machined can not support the workpiece. portion does not contact the guide bush. Disadvantages:The pre-stage machining may cause fractures, because of interrupted machining. ¢ Countermeasure against peeled surface in face back turning When peeled surface occurs on the workpiece face, please apply the countermeasures below. l Countermeasures 1 l Countermeasures 2 Face finishing Face finishing after grooving External External (1) Plunging (2) Face finishing (1) Machining by grooving toolholder (2) Face finishing E15