Основной каталог Kyocera 2016-2017 - страница 228

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

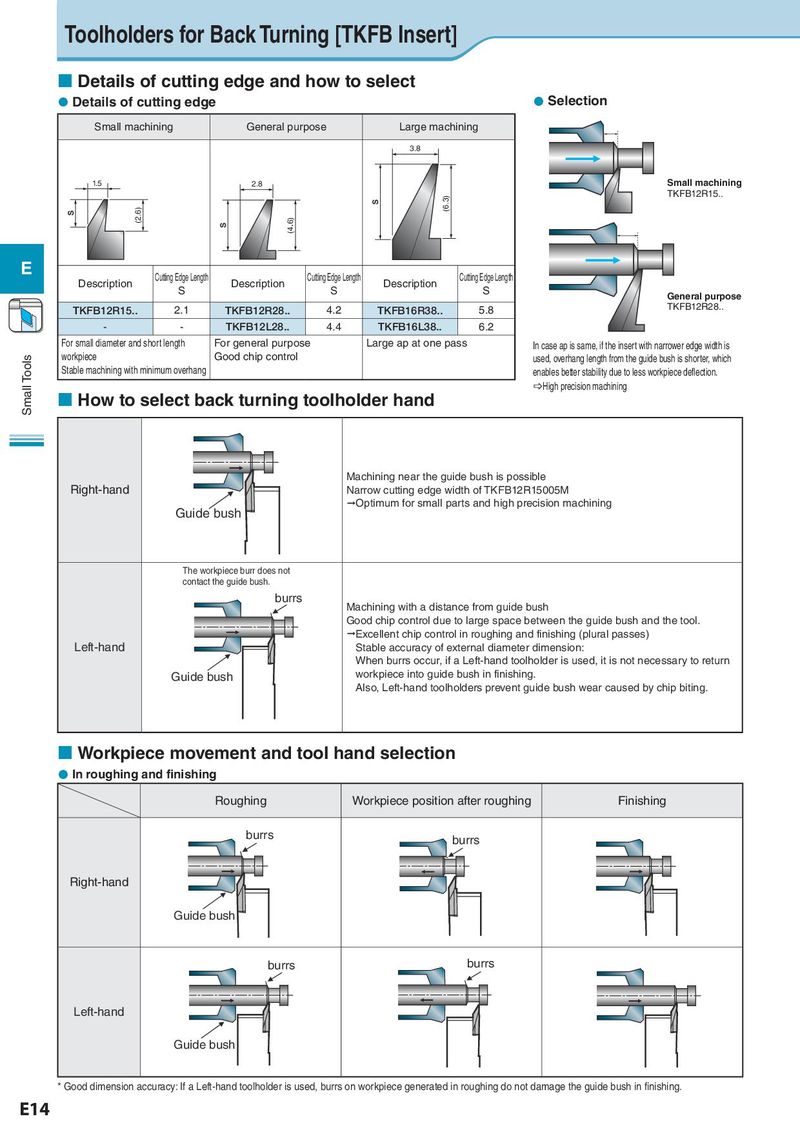

Toolholders for Back Turning [TKFB Insert] ¢ Details of cutting edge and how to select l Details of cutting edge l Selection Small machining General purpose Large machining 3.8 1.5 2.8 Small machining (6.3) TKFB12R15.. S S (2.6) S (4.6) E Cutting Edge Length Cutting Edge Length Cutting Edge Length Description S Description S Description S General purpose TKFB12R15.. 2.1 TKFB12R28.. 4.2 TKFB16R38.. 5.8 TKFB12R28.. - - TKFB12L28.. 4.4 TKFB16L38.. 6.2 For small diameter and short length For general purpose Large ap at one pass In case ap is same, if the insert with narrower edge width is Small Tools workpiece Good chip control used, overhang length from the guide bush is shorter, which Stable machining with minimum overhang enables better stability due to less workpiece deflection. _High precision machining ¢ How to select back turning toolholder hand Machining near the guide bush is possible Right-hand Narrow cutting edge width of TKFB12R15005M Guide bush "Optimum for small parts and high precision machining The workpiece burr does not contact the guide bush. burrs Machining with a distance from guide bush Good chip control due to large space between the guide bush and the tool. "Excellent chip control in roughing and finishing (plural passes) Left-hand Stable accuracy of external diameter dimension: When burrs occur, if a Left-hand toolholder is used, it is not necessary to return Guide bush workpiece into guide bush in finishing. Also, Left-hand toolholders prevent guide bush wear caused by chip biting. ¢ Workpiece movement and tool hand selection l In roughing and finishing Roughing Workpiece position after roughing Finishing burrs burrs Right-hand Guide bush burrs burrs Left-hand Guide bush * Good dimension accuracy: If a Left-hand toolholder is used, burrs on workpiece generated in roughing do not damage the guide bush in finishing. E14