Основной каталог Kyocera 2016-2017 - страница 21

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

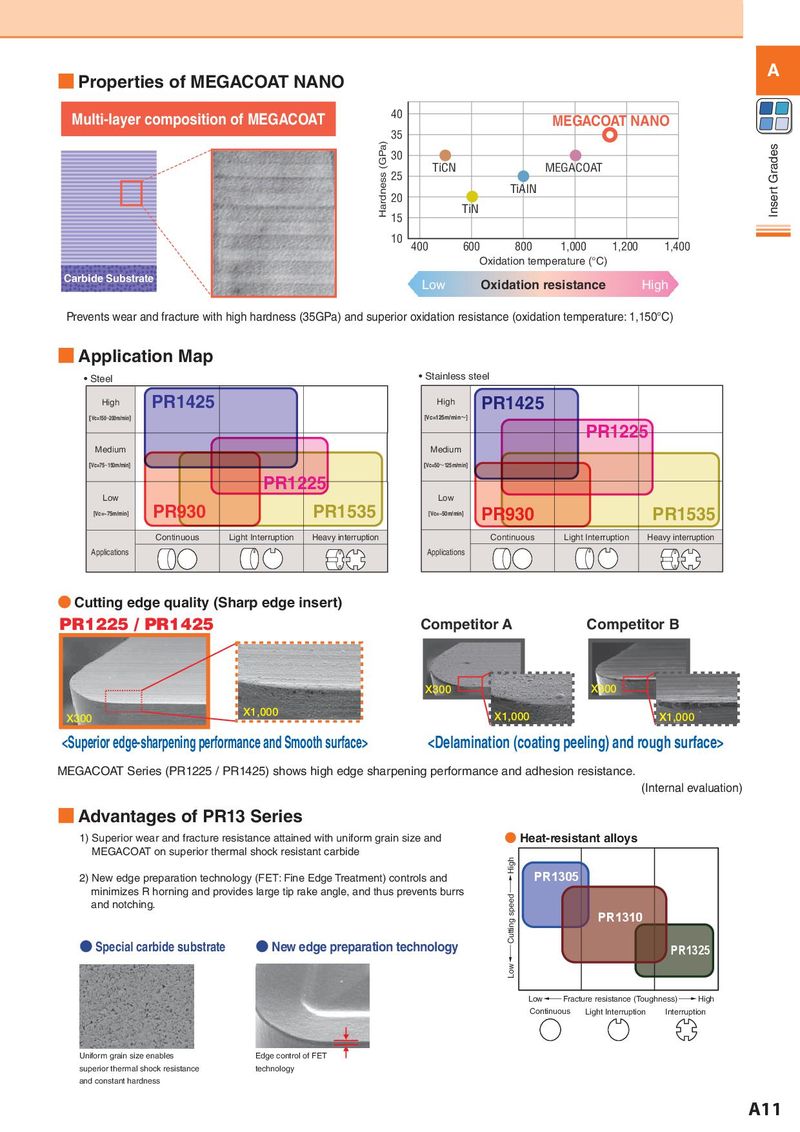

■ Properties of MEGACOAT NANO A

Multi-layer composition of MEGACOAT 40 MEGACOAT NANO

Hardness (GPa) 35

30 Insert Grades

25 TiCN MEGACOAT

20 TiAIN

15 TiN

10 400 600 800 1,000 1,200 1,400

Oxidation temperature (°C)

Carbide Substrate Low Oxidation resistance High

Prevents wear and fracture with high hardness (35GPa) and superior oxidation resistance (oxidation temperature: 1,150°C)

■ Application Map

• Steel • Stainless steel

High PR1425 High PR1425

[Vc=150~200m/min] [Vc=125m/min~]

PR1225

Medium Medium

[Vc=75~150m/min] [Vc=50~125m/min]

PR1225

Low Low

[Vc=~75m/min] PR930 PR1535 [Vc=~50m/min] PR930 PR1535

Continuous Light Interruption Heavy interruption Continuous Light Interruption Heavy interruption

Applications Applications

● Cutting edge quality (Sharp edge insert)

PR1225 / PR1425 Competitor A Competitor B

X300 X300

X300 X1,000 X1,000 X1,000