Основной каталог Kyocera 2016-2017 - страница 22

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

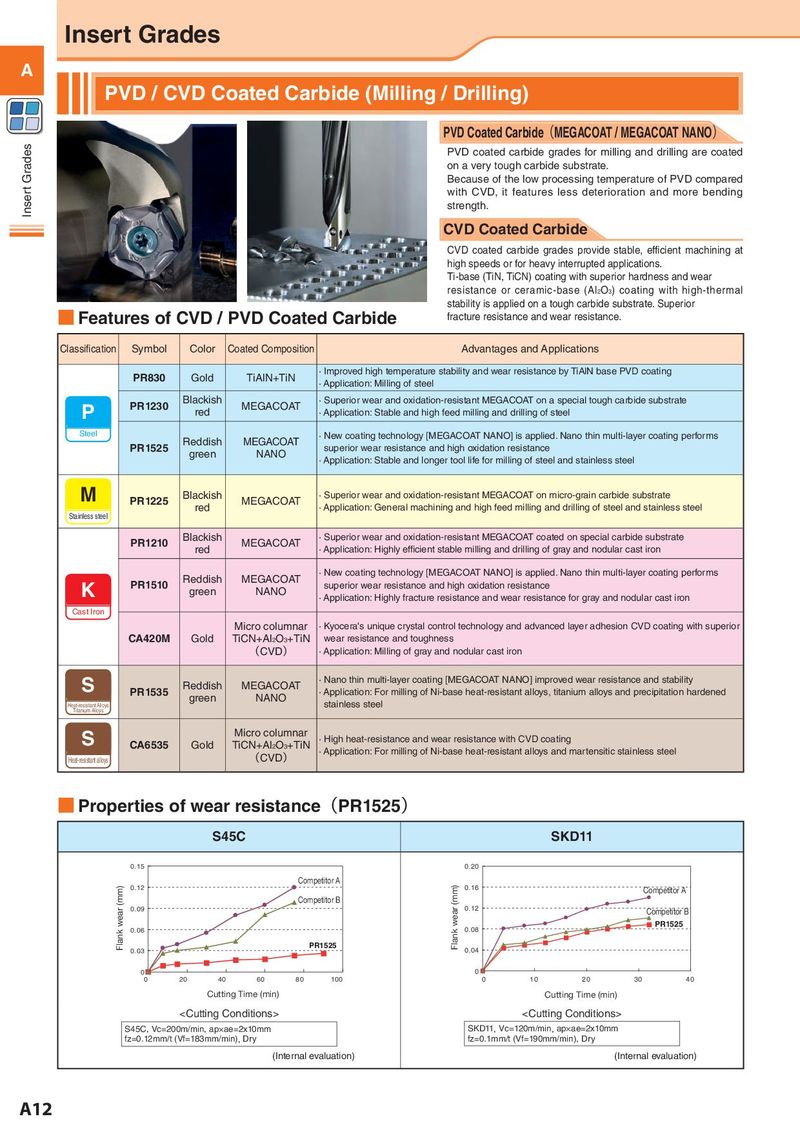

Insert Grades

A

PVD / CVD Coated Carbide (Milling / Drilling)

PVD Coated Carbide(MEGACOAT / MEGACOAT NANO)

Insert Grades PVD coated carbide grades for milling and drilling are coated

on a very tough carbide substrate.

Because of the low processing temperature of PVD compared

with CVD, it features less deterioration and more bending

strength.

CVD Coated Carbide

CVD coated carbide grades provide stable, efficient machining at

high speeds or for heavy interrupted applications.

Ti-base (TiN, TiCN) coating with superior hardness and wear

resistance or ceramic-base (Al2O3) coating with high-thermal

stability is applied on a tough carbide substrate. Superior

■ Features of CVD / PVD Coated Carbide fracture resistance and wear resistance.

Classification Symbol Color Coated Composition Advantages and Applications

PR830 Gold TiAlN+TiN · Improved high temperature stability and wear resistance by TiAlN base PVD coating

· Application: Milling of steel

P PR1230 Blackish MEGACOAT · Superior wear and oxidation-resistant MEGACOAT on a special tough carbide substrate

red · Application: Stable and high feed milling and drilling of steel

Steel Reddish MEGACOAT · New coating technology [MEGACOAT NANO] is applied. Nano thin multi-layer coating performs

PR1525 green NANO superior wear resistance and high oxidation resistance

· Application: Stable and longer tool life for milling of steel and stainless steel

M PR1225 Blackish MEGACOAT · Superior wear and oxidation-resistant MEGACOAT on micro-grain carbide substrate

red · Application: General machining and high feed milling and drilling of steel and stainless steel

Stainless steel

PR1210 Blackish MEGACOAT · Superior wear and oxidation-resistant MEGACOAT coated on special carbide substrate

red · Application: Highly efficient stable milling and drilling of gray and nodular cast iron

Reddish MEGACOAT · New coating technology [MEGACOAT NANO] is applied. Nano thin multi-layer coating performs

K PR1510 green NANO superior wear resistance and high oxidation resistance

· Application: Highly fracture resistance and wear resistance for gray and nodular cast iron

Cast Iron

Micro columnar · Kyocera's unique crystal control technology and advanced layer adhesion CVD coating with superior

CA420M Gold TiCN+Al2O3+TiN wear resistance and toughness

(CVD) · Application: Milling of gray and nodular cast iron

S Reddish MEGACOAT · Nano thin multi-layer coating [MEGACOAT NANO] improved wear resistance and stability

PR1535 green NANO · Application: For milling of Ni-base heat-resistant alloys, titanium alloys and precipitation hardened

Heat-resistant Alloys stainless steel

Titanium Alloys

S Micro columnar · High heat-resistance and wear resistance with CVD coating

CA6535 Gold TiCN+Al2O3+TiN · Application: For milling of Ni-base heat-resistant alloys and martensitic stainless steel

Heat-resistant alloys (CVD)

■ Properties of wear resistance(PR1525)

S45C SKD11

0.15 0.20

Competitor A Flank wear (mm)

Flank wear (mm) 0.12 0.16 Competitor A

Competitor B

0.09 0.12 Competitor B

0.06 0.08 PR1525

0.03 PR1525 0.04

0 0

0 20 40 60 80 100 0 10 20 30 40

Cutting Time (min) Cutting Time (min)