Основной каталог Kyocera 2016-2017 - страница 142

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

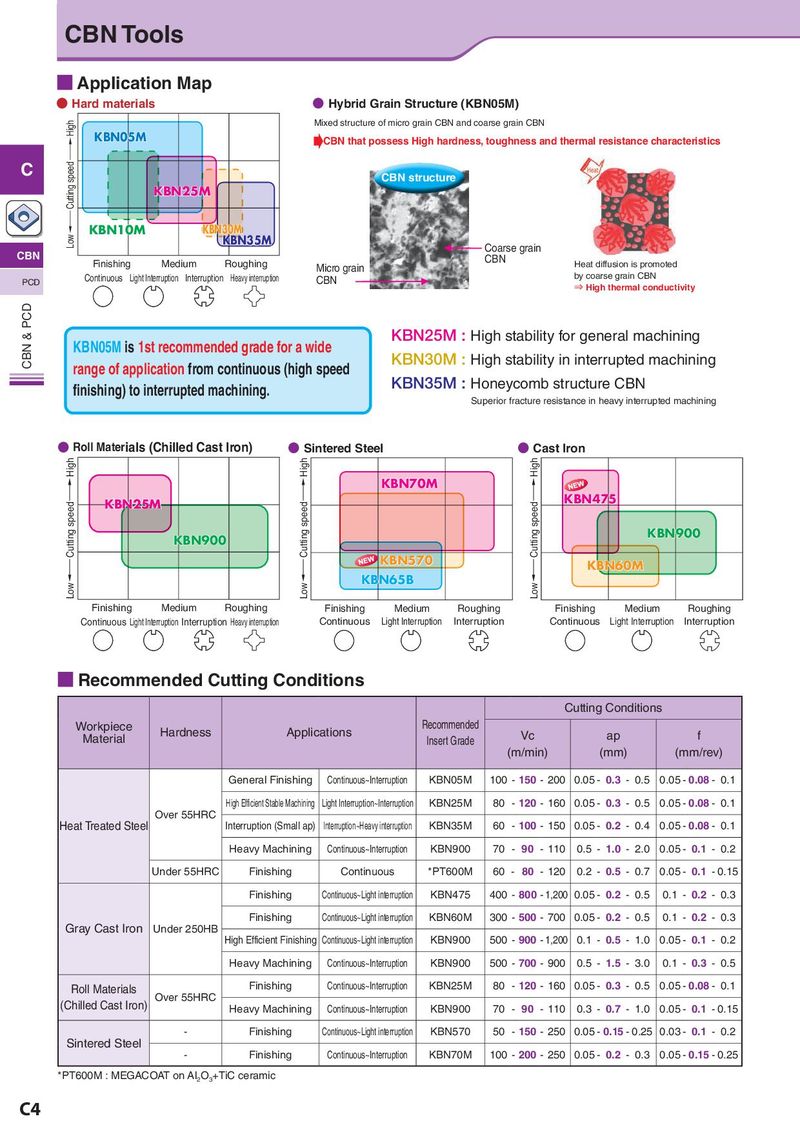

CBN Tools ■ Application Map ● Hard materials ● Hybrid Grain Structure (KBN05M) High Mixed structure of micro grain CBN and coarse grain CBN KBN05M CBN that possess High hardness, toughness and thermal resistance characteristics C Cutting speed → CBN structure KBN25M Low ← KBN10M KBN30M KBN35M Coarse grain CBN Finishing Medium Roughing CBN Heat diffusion is promoted Micro grain by coarse grain CBN PCD Continuous Light Interruption Interruption Heavy interruption CBN ⇒ High thermal conductivity CBN & PCD KBN05M is 1st recommended grade for a wide KBN25M : High stability for general machining range of application from continuous (high speed KBN30M : High stability in interrupted machining finishing) to interrupted machining. KBN35M : Honeycomb structure CBN Superior fracture resistance in heavy interrupted machining ● Roll Materials (Chilled Cast Iron) ● Sintered Steel ● Cast Iron High High High KBN70M Cutting speed→ KBN25M Cutting speed→ Cutting speed→ KBN475 KBN900 KBN900 KBN570 KBN60M Low ← Low ← KBN65B Low ← Finishing Medium Roughing Finishing Medium Roughing Finishing Medium Roughing Continuous Light Interruption Interruption Heavy interruption Continuous Light Interruption Interruption Continuous Light Interruption Interruption ■ Recommended Cutting Conditions Cutting Conditions Workpiece Hardness Applications Recommended Material Insert Grade Vc ap f (m/min) (mm) (mm/rev) General Finishing Continuous~Interruption KBN05M 100 - 150 - 200 0.05 - 0.3 - 0.5 0.05 - 0.08 - 0.1 High Efficient Stable Machining Light Interruption~Interruption KBN25M 80 - 120 - 160 0.05 - 0.3 - 0.5 0.05 - 0.08 - 0.1 Over 55HRC Heat Treated Steel Interruption (Small ap) Interruption~Heavy interruption KBN35M 60 - 100 - 150 0.05 - 0.2 - 0.4 0.05 - 0.08 - 0.1 Heavy Machining Continuous~Interruption KBN900 70 - 90 - 110 0.5 - 1.0 - 2.0 0.05 - 0.1 - 0.2 Under 55HRC Finishing Continuous *PT600M 60 - 80 - 120 0.2 - 0.5 - 0.7 0.05 - 0.1 - 0.15 Finishing Continuous~Light interruption KBN475 400 - 800 - 1,200 0.05 - 0.2 - 0.5 0.1 - 0.2 - 0.3 Finishing Continuous~Light interruption KBN60M 300 - 500 - 700 0.05 - 0.2 - 0.5 0.1 - 0.2 - 0.3 Gray Cast Iron Under 250HB High Efficient Finishing Continuous~Light interruption KBN900 500 - 900 - 1,200 0.1 - 0.5 - 1.0 0.05 - 0.1 - 0.2 Heavy Machining Continuous~Interruption KBN900 500 - 700 - 900 0.5 - 1.5 - 3.0 0.1 - 0.3 - 0.5 Roll Materials Finishing Continuous~Interruption KBN25M 80 - 120 - 160 0.05 - 0.3 - 0.5 0.05 - 0.08 - 0.1 (Chilled Cast Iron) Over 55HRC Heavy Machining Continuous~Interruption KBN900 70 - 90 - 110 0.3 - 0.7 - 1.0 0.05 - 0.1 - 0.15 - Finishing Continuous~Light interruption KBN570 50 - 150 - 250 0.05 - 0.15 - 0.25 0.03 - 0.1 - 0.2 Sintered Steel - Finishing Continuous~Interruption KBN70M 100 - 200 - 250 0.05 - 0.2 - 0.3 0.05 - 0.15 - 0.25 *PT600M : MEGACOAT on Al2O3+TiC ceramic C4