Основной каталог Kyocera 2016-2017 - страница 143

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

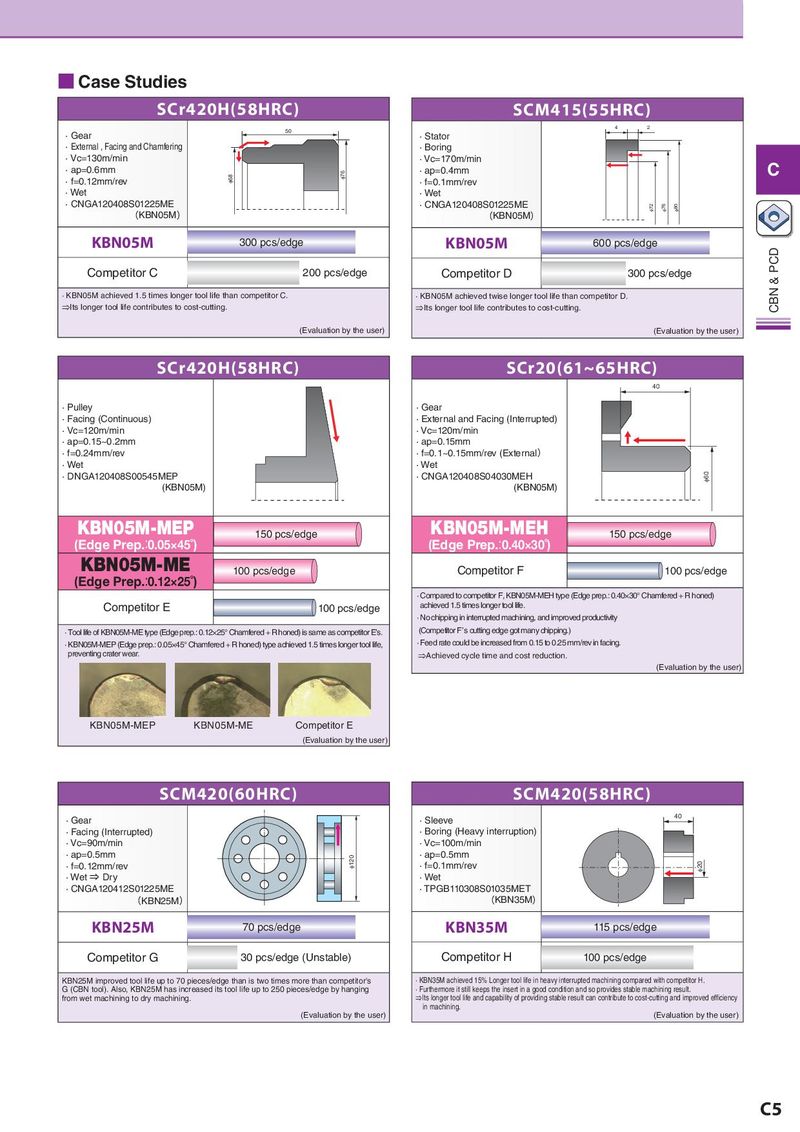

■ Case Studies SCr420H(58HRC) SCM415(55HRC) 50 4 2 · Gear · Stator · External , Facing and Chamfering · Boring · Vc=130m/min · Vc=170m/min C · ap=0.6mm φ68 φ76 · ap=0.4mm · f=0.12mm/rev · f=0.1mm/rev · Wet · Wet · CNGA120408S01225ME · CNGA120408S01225ME φ72 φ76 φ80 (KBN05M) (KBN05M) KBN05M 300 pcs/edge KBN05M 600 pcs/edge CBN & PCD Competitor C 200 pcs/edge Competitor D 300 pcs/edge · KBN05M achieved 1.5 times longer tool life than competitor C. · KBN05M achieved twise longer tool life than competitor D. ⇒Its longer tool life contributes to cost-cutting. ⇒Its longer tool life contributes to cost-cutting. (Evaluation by the user) (Evaluation by the user) SCr420H(58HRC) SCr20(61~65HRC) 40 · Pulley · Gear · Facing (Continuous) · External and Facing (Interrupted) · Vc=120m/min · Vc=120m/min · ap=0.15~0.2mm · ap=0.15mm · f=0.24mm/rev · f=0.1~0.15mm/rev (External) · Wet · Wet · DNGA120408S00545MEP · CNGA120408S04030MEH φ60 (KBN05M) (KBN05M) KBN05M-MEP 150 pcs/edge KBN05M-MEH 150 pcs/edge (Edge Prep:. 0.05×45˚) (Edge Prep:. 0.40×30˚) KBN05M-ME 100 pcs/edge Competitor F 100 pcs/edge (Edge Prep:. 0.12×25˚) · Compared to competitor F, KBN05M-MEH type (Edge prep.: 0.40×30° Chamfered + R honed) Competitor E 100 pcs/edge achieved 1.5 times longer tool life. · No chipping in interrupted machining, and improved productivity · Tool life of KBN05M-ME type (Edge prep.: 0.12×25° Chamfered + R honed) is same as competitor E’s. (Competitor F’s cutting edge got many chipping.) · KBN05M-MEP (Edge prep.: 0.05×45° Chamfered + R honed) type achieved 1.5 times longer tool life, · Feed rate could be increased from 0.15 to 0.25 mm/rev in facing. preventing crater wear. ⇒Achieved cycle time and cost reduction. (Evaluation by the user) KBN05M-MEP KBN05M-ME Competitor E (Evaluation by the user) SCM420(60HRC) SCM420(58HRC) · Gear · Sleeve 40 · Facing (Interrupted) · Boring (Heavy interruption) · Vc=90m/min · Vc=100m/min · ap=0.5mm φ120 · ap=0.5mm · f=0.12mm/rev · f=0.1mm/rev φ20 · Wet ⇒ Dry · Wet · CNGA120412S01225ME · TPGB110308S01035MET (KBN25M) (KBN35M) KBN25M 70 pcs/edge KBN35M 115 pcs/edge Competitor G 30 pcs/edge (Unstable) Competitor H 100 pcs/edge KBN25M improved tool life up to 70 pieces/edge than is two times more than competitor's · KBN35M achieved 15% Longer tool life in heavy interrupted machining compared with competitor H. G (CBN tool). Also, KBN25M has increased its tool life up to 250 pieces/edge by hanging · Furthermore it still keeps the insert in a good condition and so provides stable machining result. from wet machining to dry machining. ⇒Its longer tool life and capability of providing stable result can contribute to cost-cutting and improved efficiency in machining. (Evaluation by the user) (Evaluation by the user) C5