Основной каталог Kennametal вращающиеся инструменты 2018 - страница 1891

Навигация

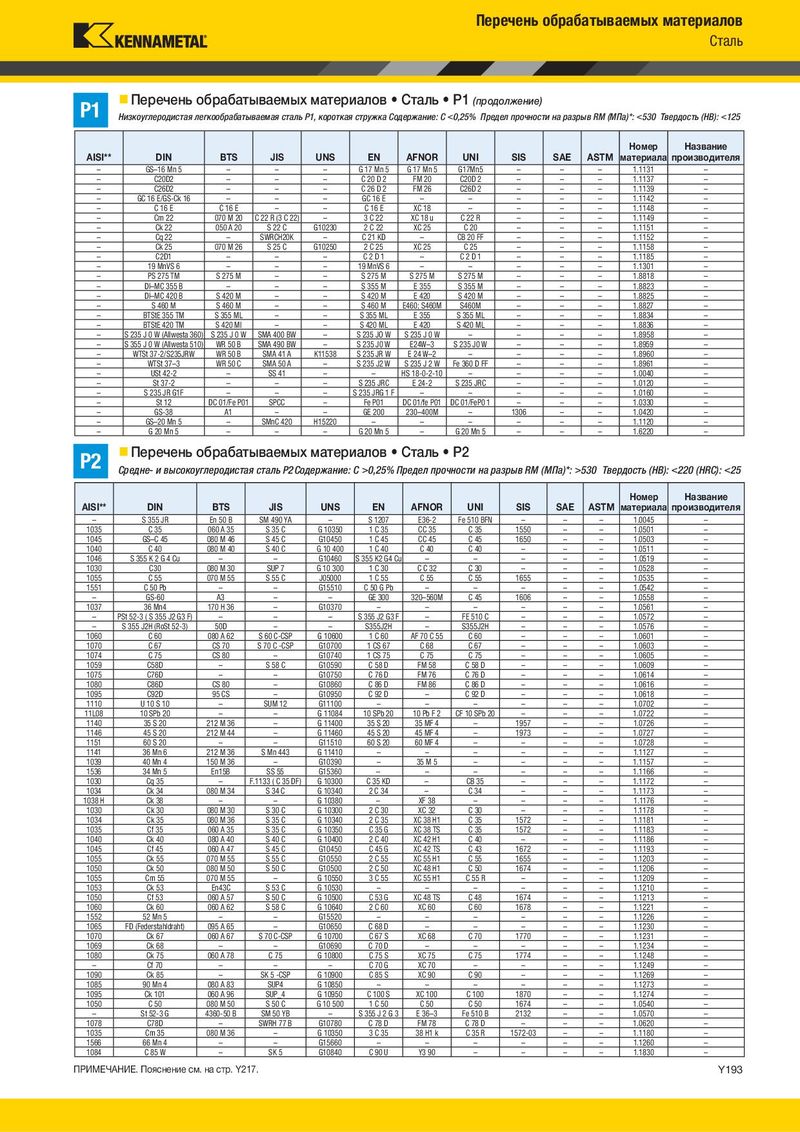

Перечень обрабатываемых материалов Сталь P1 Перечень обрабатываемых материалов • Сталь • P1 (продолжение) Низкоуглеродистая легкообрабатываемая сталь P1, короткая стружка Содержание: C <0,25% Предел прочности на разрыв RM (МПа)*: <530 Твердость (HB): <125 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – GS–16 Mn 5 – – – G 17 Mn 5 G 17 Mn 5 G17Mn5 – – – 1.1131 – – C20D2 – – – C 20 D 2 FM 20 C20D 2 – – – 1.1137 – – C26D2 – – – C 26 D 2 FM 26 C26D 2 – – – 1.1139 – – GC 16 E/GS-Ck 16 – – – GC 16 E – – – – – 1.1142 – – C 16 E C 16 E – – C 16 E XC 18 – – – – 1.1148 – – Cm 22 070 M 20 C 22 R (3 C 22) – 3 C 22 XC 18 u C 22 R – – – 1.1149 – – Ck 22 050 A 20 S 22 C G10230 2 C 22 XC 25 C 20 – – – 1.1151 – – Cq 22 – SWRCH20K – C 21 KD – CB 20 FF – – – 1.1152 – – Ck 25 070 M 26 S 25 C G10250 2 C 25 XC 25 C 25 – – – 1.1158 – – C2D1 – – – C2D1 – C2D1 – – – 1.1185 – – 19 MnVS 6 – – – 19 MnVS 6 – – – – – 1.1301 – – PS 275 TM S 275 M – – S 275 M S 275 M S 275 M – – – 1.8818 – – DI–MC 355 B – – – S 355 M E 355 S 355 M – – – 1.8823 – – DI–MC 420 B S 420 M – – S 420 M E 420 S 420 M – – – 1.8825 – – S 460 M S 460 M – – S 460 M E460; S460M S460M – – – 1.8827 – – BTStE 355 TM S 355 ML – – S 355 ML E 355 S 355 ML – – – 1.8834 – – BTStE 420 TM S 420 Ml – – S 420 ML E 420 S 420 ML – – – 1.8836 – – S 235 J 0 W (Allwesta 360) S 235 J 0 W SMA 400 BW – S 235 JO W S 235 J 0 W – – – – 1.8958 – – S 355 J 0 W (Allwesta 510) WR 50 B SMA 490 BW – S 235 J0 W E24W–3 S 235 J0 W – – – 1.8959 – – WTSt 37-2/S235JRW WR 50 B SMA 41 A K11538 S 235 JR W E 24 W–2 – – – – 1.8960 – – WTSt 37–3 WR 50 C SMA 50 A – S 235 J2 W S 235 J 2 W Fe 360 D FF – – – 1.8961 – – USt 42-2 – SS 41 – – HS 18-0-2-10 – – – – 1.0040 – – St 37-2 – – – S 235 JRC E 24-2 S 235 JRC – – – 1.0120 – – S 235 JR G1F – – – S 235 JRG 1 F – – – – – 1.0160 – – St 12 DC 01/Fe P01 SPCC – Fe P01 DC 01/fe P01 DC 01/FeP0 1 – – – 1.0330 – – GS-38 A1 – – GE 200 230–400M – 1306 – – 1.0420 – – GS–20 Mn 5 – SMnC 420 H15220 – – – – – – 1.1120 – – G 20 Mn 5 – – – G 20 Mn 5 – G 20 Mn 5 – – – 1.6220 – P2 Перечень обрабатываемых материалов • Сталь • P2 Средне- и высокоуглеродистая сталь P2 Содержание: C >0,25% Предел прочности на разрыв RM (МПа)*: >530 Твердость (HB): <220 (HRC): <25 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – S 355 JR En 50 B SM 490 YA – S 1207 E36-2 Fe 510 BFN – – – 1.0045 – 1035 C 35 060 A 35 S 35 C G 10350 1 C 35 CC 35 C 35 1550 – – 1.0501 – 1045 GS–C 45 080 M 46 S 45 C G10450 1 C 45 CC 45 C 45 1650 – – 1.0503 – 1040 C 40 080 M 40 S 40 C G 10 400 1 C 40 C 40 C 40 – – – 1.0511 – 1046 S 355 K 2 G 4 Cu – – G10460 S 355 K2 G4 Cu – – – – – 1.0519 – 1030 C30 080 M 30 SUP 7 G 10 300 1 C 30 C C 32 C 30 – – – 1.0528 – 1055 C 55 070 M 55 S 55 C J05000 1 C 55 C 55 C 55 1655 – – 1.0535 – 1551 C 50 Pb – – G15510 C 50 G Pb – – – – – 1.0542 – – GS-60 A3 – – GE 300 320–560M C 45 1606 – – 1.0558 – 1037 36 Mn4 170 H 36 – G10370 – – – – – – 1.0561 – – PSt 52-3 ( S 355 J2 G3 F) – – – S 355 J2 G3 F – FE 510 C – – – 1.0572 – – S 355 J2H (RoSt 52-3) 50D – – S355J2H – S355J2H – – – 1.0576 – 1060 C 60 080 A 62 S 60 C-CSP G 10600 1 C 60 AF 70 C 55 C 60 – – – 1.0601 – 1070 C 67 CS 70 S 70 C -CSP G10700 1 CS 67 C 68 C 67 – – – 1.0603 – 1074 C 75 CS 80 – G10740 1 CS 75 C 75 C 75 – – – 1.0605 – 1059 C58D – S 58 C G10590 C 58 D FM 58 C 58 D – – – 1.0609 – 1075 C76D – – G10750 C 76 D FM 76 C 76 D – – – 1.0614 – 1080 C86D CS 80 – G10860 C 86 D FM 86 C 86 D – – – 1.0616 – 1095 C92D 95 CS – G10950 C 92 D – C 92 D – – – 1.0618 – 1110 U 10 S 10 – SUM 12 G11100 – – – – – – 1.0702 – 11L08 10 SPb 20 – – G 11084 10 SPb 20 10 Pb F 2 CF 10 SPb 20 – – – 1.0722 – 1140 35 S 20 212 M 36 – G 11400 35 S 20 35 MF 4 – 1957 – – 1.0726 – 1146 45 S 20 212 M 44 – G 11460 45 S 20 45 MF 4 – 1973 – – 1.0727 – 1151 60 S 20 – – G11510 60 S 20 60 MF 4 – – – – 1.0728 – 1141 36 Mn 6 212 M 36 S Mn 443 G 11410 – – – – – – 1.1127 – 1039 40 Mn 4 150 M 36 – G10390 – 35 M 5 – – – – 1.1157 – 1536 34 Mn 5 En15B SS 55 G15360 – – – – – – 1.1166 – 1030 Cq 35 – F.1133 ( C 35 DF) G 10300 C 35 KD – CB 35 – – – 1.1172 – 1034 Ck 34 080 M 34 S 34 C G 10340 2 C 34 – C 34 – – – 1.1173 – 1038 H Ck 38 – – G 10380 – XF 38 – – – – 1.1176 – 1030 Ck 30 080 M 30 S 30 C G 10300 2 C 30 XC 32 C 30 – – – 1.1178 – 1034 Ck 35 080 M 36 S 35 C G 10340 2 C 35 XC 38 H1 C 35 1572 – – 1.1181 – 1035 Cf 35 060 A 35 S 35 C G 10350 C 35 G XC 38 TS C 35 1572 – – 1.1183 – 1040 Ck 40 080 A 40 S 40 C G 10400 2 C 40 XC 42 H1 C 40 – – – 1.1186 – 1045 Cf 45 060 A 47 S 45 C G10450 C 45 G XC 42 TS C 43 1672 – – 1.1193 – 1055 Ck 55 070 M 55 S 55 C G10550 2 C 55 XC 55 H1 C 55 1655 – – 1.1203 – 1050 Ck 50 080 M 50 S 50 C G10500 2 C 50 XC 48 H1 C 50 1674 – – 1.1206 – 1055 Cm 55 070 M 55 – G 10550 3 C 55 XC 55 H1 C 55 R – – – 1.1209 – 1053 Ck 53 En43C S 53 C G 10530 – – – – – – 1.1210 – 1050 Cf 53 060 A 57 S 50 C G 10500 C 53 G XC 48 TS C 48 1674 – – 1.1213 – 1060 Ck 60 060 A 62 S 58 C G 10640 2 C 60 XC 60 C 60 1678 – – 1.1221 – 1552 52 Mn 5 – – G15520 – – – – – – 1.1226 – 1065 FD (Federstahldraht) 095 A 65 – G10650 C 68 D – – – – – 1.1230 – 1070 Ck 67 060 A 67 S 70 C-CSP G 10700 C 67 S XC 68 C 70 1770 – – 1.1231 – 1069 Ck 68 – – G10690 C 70 D – – – – – 1.1234 – 1080 Ck 75 060 A 78 C 75 G 10800 C 75 S XC 75 C 75 1774 – – 1.1248 – – Cf 70 – – – C 70 G XC 70 – – – – 1.1249 – 1090 Ck 85 – SK 5 -CSP G 10900 C 85 S XC 90 C 90 – – – 1.1269 – 1085 90 Mn 4 080 A 83 SUP4 G 10850 – – – – – – 1.1273 – 1095 Ck 101 060 A 96 SUP_4 G 10950 C 100 S XC 100 C 100 1870 – – 1.1274 – 1050 C 50 080 M 50 S 50 C G 10 500 1 C 50 C 50 C 50 1674 – – 1.0540 – – St 52-3 G 4360-50 B SM 50 YB – S 355 J 2 G 3 E 36–3 Fe 510 B 2132 – – 1.0570 – 1078 C78D – SWRH 77 B G10780 C 78 D FM 78 C 78 D – – – 1.0620 – 1035 Cm 35 080 M 36 – G 10350 3 C 35 38 H1 k C 35 R 1572-03 – – 1.1180 – 1566 66 Mn 4 – – G15660 – – – – – – 1.1260 – 1084 C 85 W – SK 5 G10840 C 90 U Y3 90 – – – – 1.1830 – ПРИМЕЧАНИЕ. Пояснение см. на стр. Y217. Y193

Каталог Kennametal инновации 2021.1

Каталог Kennametal инновации 2021.1 Каталог Kennametal инновации 2022.2

Каталог Kennametal инновации 2022.2 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1