Основной каталог Kennametal вращающиеся инструменты 2018 - страница 1890

Навигация

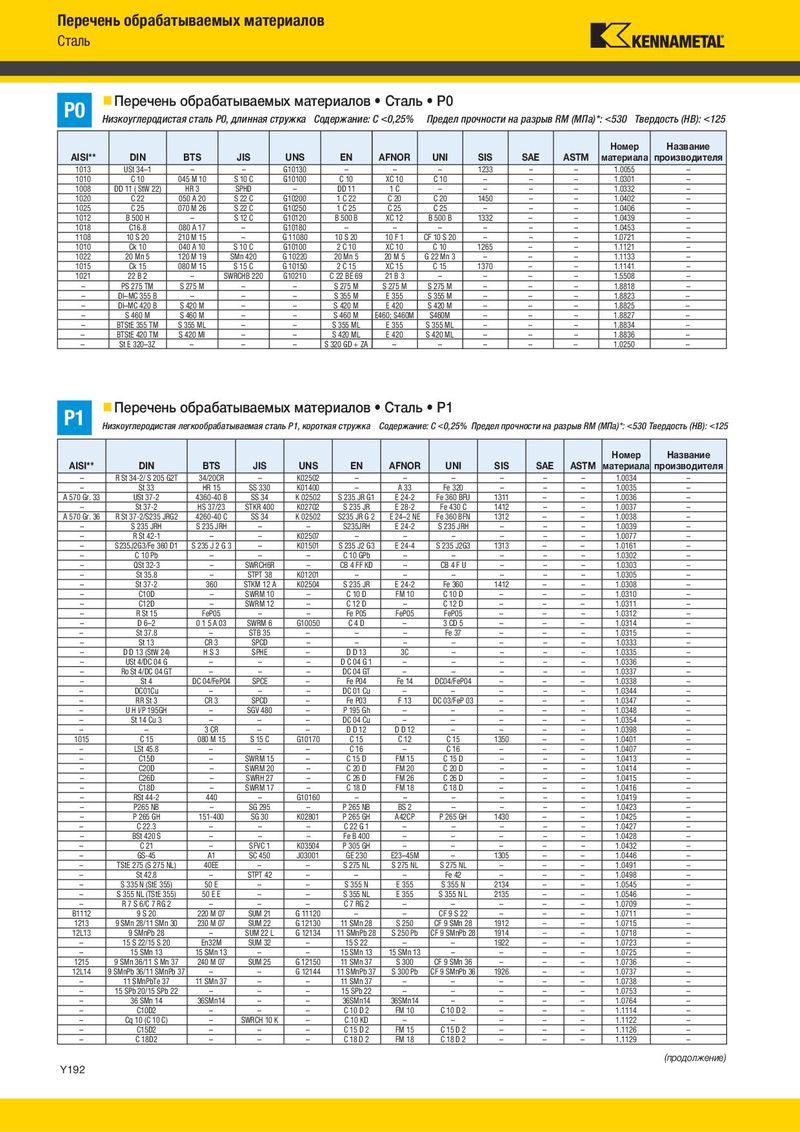

Перечень обрабатываемых материалов Сталь P0 Перечень обрабатываемых материалов • Сталь • P0 Низкоуглеродистая сталь P0, длинная стружка Содержание: C <0,25% Предел прочности на разрыв RM (МПа)*: <530 Твердость (HB): <125 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя 1013 USt 34–1 – – G10130 – – – 1233 – – 1.0055 – 1010 C 10 045 M 10 S 10 C G10100 C 10 XC 10 C 10 – – – 1.0301 – 1008 DD 11 ( StW 22) HR 3 SPHD – DD 11 1C – – – – 1.0332 – 1020 C 22 050 A 20 S 22 C G10200 1 C 22 C 20 C 20 1450 – – 1.0402 – 1025 C 25 070 M 26 S 22 C G10250 1 C 25 C 25 C 25 – – – 1.0406 – 1012 B 500 H – S 12 C G10120 B 500 B XC 12 B 500 B 1332 – – 1.0439 – 1018 C16.8 080 A 17 – G10180 – – – – – – 1.0453 – 1108 10 S 20 210 M 15 – G 11080 10 S 20 10 F 1 CF 10 S 20 – – – 1.0721 – 1010 Ck 10 040 A 10 S 10 C G10100 2 C 10 XC 10 C 10 1265 – – 1.1121 – 1022 20 Mn 5 120 M 19 SMn 420 G 10220 20 Mn 5 20 M 5 G 22 Mn 3 – – – 1.1133 – 1015 Ck 15 080 M 15 S 15 C G 10150 2 C 15 XC 15 C 15 1370 – – 1.1141 – 1021 22 B 2 – SWRCHB 220 G10210 C 22 BE 69 21 B 3 – – – – 1.5508 – – PS 275 TM S 275 M – – S 275 M S 275 M S 275 M – – – 1.8818 – – DI–MC 355 B – – – S 355 M E 355 S 355 M – – – 1.8823 – – DI–MC 420 B S 420 M – – S 420 M E 420 S 420 M – – – 1.8825 – – S 460 M S 460 M – – S 460 M E460; S460M S460M – – – 1.8827 – – BTStE 355 TM S 355 ML – – S 355 ML E 355 S 355 ML – – – 1.8834 – – BTStE 420 TM S 420 Ml – – S 420 ML E 420 S 420 ML – – – 1.8836 – – St E 320–3Z – – – S 320 GD + ZA – – – – – 1.0250 – P1 Перечень обрабатываемых материалов • Сталь • P1 Низкоуглеродистая легкообрабатываемая сталь P1, короткая стружка Содержание: C <0,25% Предел прочности на разрыв RM (МПа)*: <530 Твердость (HB): <125 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – R St 34-2/ S 205 G2T 34/20CR – K02502 – – – – – – 1.0034 – – St 33 HR 15 SS 330 K01400 – A 33 Fe 320 – – – 1.0035 – A 570 Gr. 33 USt 37-2 4360-40 B SS 34 K 02502 S 235 JR G1 E 24-2 Fe 360 BFU 1311 – – 1.0036 – – St 37-2 HS 37/23 STKR 400 K02702 S 235 JR E 28-2 Fe 430 C 1412 – – 1.0037 – A 570 Gr. 36 R St 37-2/S235 JRG2 4260-40 C SS 34 K 02502 S235 JR G 2 E 24–2 NE Fe 360 BFN 1312 – – 1.0038 – – S 235 JRH S 235 JRH – – S235JRH E 24-2 S 235 JRH – – – 1.0039 – – R St 42-1 – – K02507 – – – – – – 1.0077 – – S235J2G3/Fe 360 D1 S 235 J 2 G 3 – K01501 S 235 J2 G3 E 24-4 S 235 J2G3 1313 – – 1.0161 – – C 10 Pb – – – C 10 GPb – – – – – 1.0302 – – QSt 32-3 – SWRCH6R – CB 4 FF KD – CB 4 F U – – – 1.0303 – – St 35.8 – STPT 38 K01201 – – – – – – 1.0305 – – St 37-2 360 STKM 12 A K02504 S 235 JR E 24-2 Fe 360 1412 – – 1.0308 – – C10D – SWRM 10 – C 10 D FM 10 C 10 D – – – 1.0310 – – C12D – SWRM 12 – C 12 D – C 12 D – – – 1.0311 – – R St 15 FeP05 – – Fe P05 FeP05 FeP05 – – – 1.0312 – – D 6–2 0 1 5 A 03 SWRM 6 G10050 C4D – 3 CD 5 – – – 1.0314 – – St 37.8 – STB 35 – – – Fe 37 – – – 1.0315 – – St 13 CR 3 SPCD – – – – – – – 1.0333 – – D D 13 (StW 24) HS3 SPHE – D D 13 3C – – – – 1.0335 – – USt 4/DC 04 G – – – D C 04 G 1 – – – – – 1.0336 – – Ro St 4/DC 04 GT – – – DC 04 GT – – – – – 1.0337 – – St 4 DC 04/FeP04 SPCE – Fe P04 Fe 14 DC04/FeP04 – – – 1.0338 – – DC01Cu – – – DC 01 Cu – – – – – 1.0344 – – RR St 3 CR 3 SPCD – Fe P03 F 13 DC 03/FeP 03 – – – 1.0347 – – U H I/P 195GH – SGV 480 – P 195 Gh – – – – – 1.0348 – – St 14 Cu 3 – – – DC 04 Cu – – – – – 1.0354 – – – 3 CR – – D D 12 D D 12 – – – – 1.0398 – 1015 C 15 080 M 15 S 15 C G10170 C 15 C 12 C 15 1350 – – 1.0401 – – LSt 45.8 – – – C 16 – C 16 – – – 1.0407 – – C15D – SWRM 15 – C 15 D FM 15 C 15 D – – – 1.0413 – – C20D – SWRM 20 – C 20 D FM 20 C 20 D – – – 1.0414 – – C26D – SWRH 27 – C 26 D FM 26 C 26 D – – – 1.0415 – – C18D – SWRM 17 – C 18 D FM 18 C 18 D – – – 1.0416 – – RSt 44-2 440 – G10160 – – – – – – 1.0419 – – P265 NB – SG 295 – P 265 NB BS 2 – – – – 1.0423 – – P 265 GH 151-400 SG 30 K02801 P 265 GH A42CP P 265 GH 1430 – – 1.0425 – – C 22.3 – – – C 22 G 1 – – – – – 1.0427 – – BSt 420 S – – – Fe B 400 – – – – – 1.0428 – – C 21 – SFVC 1 K03504 P 305 GH – – – – – 1.0432 – – GS-45 A1 SC 450 J03001 GE 230 E23–45M – 1305 – – 1.0446 – – TStE 275 (S 275 NL) 40EE – – S 275 NL S 275 NL S 275 NL – – – 1.0491 – – St 42.8 – STPT 42 – – – Fe 42 – – – 1.0498 – – S 335 N (StE 355) 50 E – – S 355 N E 355 S 355 N 2134 – – 1.0545 – – S 355 NL (TStE 355) 50 E E – – S 355 NL E 355 S 355 N L 2135 – – 1.0546 – – R 7 S 6/C 7 RG 2 – – – C 7 RG 2 – – – – – 1.0709 – B1112 9 S 20 220 M 07 SUM 21 G 11120 – – CF 9 S 22 – – – 1.0711 – 1213 9 SMn 28/11 SMn 30 230 M 07 SUM 22 G 12130 11 SMn 28 S 250 CF 9 SMn 28 1912 – – 1.0715 – 12L13 9 SMnPb 28 – SUM 22 L G 12134 11 SMnPb 28 S 250 Pb CF 9 SMnPb 28 1914 – – 1.0718 – – 15 S 22/15 S 20 En32M SUM 32 – 15 S 22 – – 1922 – – 1.0723 – – 15 SMn 13 15 SMn 13 – – 15 SMn 13 15 SMn 13 – – – – 1.0725 – 1215 9 SMn 36/11 S Mn 37 240 M 07 SUM 25 G 12150 11 SMn 37 S 300 CF 9 SMn 36 – – – 1.0736 – 12L14 9 SMnPb 36/11 SMnPb 37 – – G 12144 11 SMnPb 37 S 300 Pb CF 9 SMnPb 36 1926 – – 1.0737 – – 11 SMnPbTe 37 11 SMn 37 – – 11 SMn 37 – – – – – 1.0738 – – 15 SPb 20/15 SPb 22 – – – 15 SPb 22 – – – – – 1.0753 – – 36 SMn 14 36SMn14 – – 36SMn14 36SMn14 – – – – 1.0764 – – C10D2 – – – C 10 D 2 FM 10 C 10 D 2 – – – 1.1114 – – Cq 10 (C 10 C) – SWRCH 10 K – C 10 KD – – – – – 1.1122 – – C15D2 – – – C 15 D 2 FM 15 C 15 D 2 – – – 1.1126 – – C 18D2 – – – C 18 D 2 FM 18 C 18 D 2 – – – 1.1129 – (продолжение) Y192

Каталог Kennametal инновации 2021.1

Каталог Kennametal инновации 2021.1 Каталог Kennametal инновации 2022.2

Каталог Kennametal инновации 2022.2 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1