Основной каталог Kennametal вращающиеся инструменты 2018 - страница 1892

Навигация

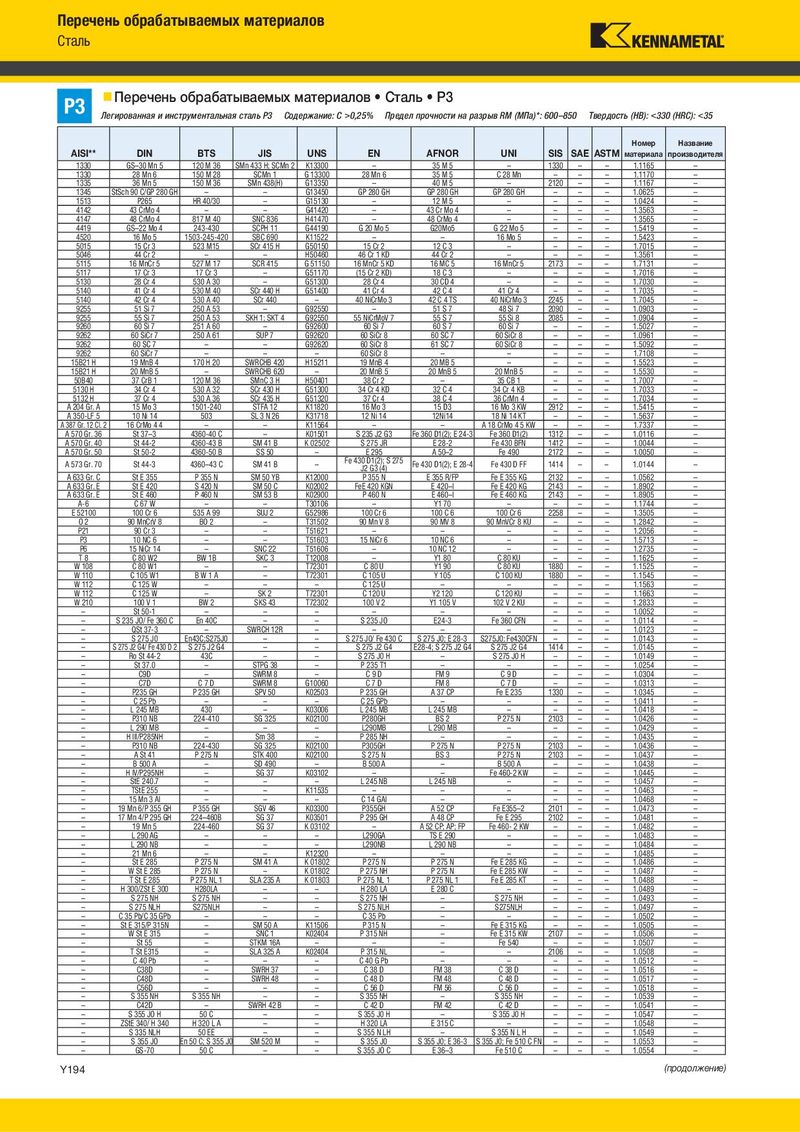

Перечень обрабатываемых материалов Сталь P3 Перечень обрабатываемых материалов • Сталь • P3 Легированная и инструментальная сталь P3 Содержание: C >0,25% Предел прочности на разрыв RM (МПа)*: 600–850 Твердость (HB): <330 (HRC): <35 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя 1330 GS–30 Mn 5 120 M 36 SMn 433 H; SCMn 2 K13300 – 35 M 5 – 1330 – – 1.1165 – 1330 28 Mn 6 150 M 28 SCMn 1 G 13300 28 Mn 6 35 M 5 C 28 Mn – – – 1.1170 – 1335 36 Mn 5 150 M 36 SMn 438(H) G13350 – 40 M 5 – 2120 – – 1.1167 – 1345 StSch 90 C/GP 280 GH – – G13450 GP 280 GH GP 280 GH GP 280 GH – – – 1.0625 – 1513 P265 HR 40/30 – G15130 – 12 M 5 – – – – 1.0424 – 4142 43 CrMo 4 – – G41420 – 43 Cr Mo 4 – – – – 1.3563 – 4147 48 CrMo 4 817 M 40 SNC 836 H41470 – 48 CrMo 4 – – – – 1.3565 – 4419 GS–22 Mo 4 243-430 SCPH 11 G44190 G 20 Mo 5 G20Mo5 G 22 Mo 5 – – – 1.5419 – 4520 16 Mo 5 1503-245-420 SBC 690 K11522 – – 16 Mo 5 – – – 1.5423 – 5015 15 Cr 3 523 M15 SCr 415 H G50150 15 Cr 2 12 C 3 – – – – 1.7015 – 5046 44 Cr 2 – – H50460 46 Cr 1 KD 44 Cr 2 – – – – 1.3561 – 5115 16 MnCr 5 527 M 17 SCR 415 G 51150 16 MnCr 5 KD 16 MC 5 16 MnCr 5 2173 – – 1.7131 – 5117 17 Cr 3 17 Cr 3 – G51170 (15 Cr 2 KD) 18 C 3 – – – – 1.7016 – 5130 28 Cr 4 530 A 30 – G51300 28 Cr 4 30 CD 4 – – – – 1.7030 – 5140 41 Cr 4 530 M 40 SCr 440 H G51400 41 Cr 4 42 C 4 41 Cr 4 – – – 1.7035 – 5140 42 Cr 4 530 A 40 SCr 440 – 40 NiCrMo 3 42 C 4 TS 40 NiCrMo 3 2245 – – 1.7045 – 9255 51 Si 7 250 A 53 – G92550 – 51 S 7 48 Si 7 2090 – – 1.0903 – 9255 55 Si 7 250 A 53 SKH 1; SKT 4 G92550 55 NiCrMoV 7 55 S 7 55 Si 8 2085 – – 1.0904 – 9260 60 Si 7 251 A 60 – G92600 60 Si 7 60 S 7 60 Si 7 – – – 1.5027 – 9262 60 SiCr 7 250 A 61 SUP 7 G92620 60 SiCr 8 60 SC 7 60 SiCr 8 – – – 1.0961 – 9262 60 SC 7 – – G92620 60 SiCr 8 61 SC 7 60 SiCr 8 – – – 1.5092 – 9262 60 SiCr 7 – – – 60 SiCr 8 – – – – – 1.7108 – 15B21 H 19 MnB 4 170 H 20 SWRCHB 420 H15211 19 MnB 4 20 MB 5 – – – – 1.5523 – 15B21 H 20 MnB 5 – SWRCHB 620 – 20 MnB 5 20 MnB 5 20 MnB 5 – – – 1.5530 – 50B40 37 CrB 1 120 M 36 SMnC 3 H H50401 38 Cr 2 – 35 CB 1 – – – 1.7007 – 5130 H 34 Cr 4 530 A 32 SCr 430 H G51300 34 Cr 4 KD 32 C 4 34 Cr 4 KB – – – 1.7033 – 5132 H 37 Cr 4 530 A 36 SCr 435 H G51320 37 Cr 4 38 C 4 36 CrMn 4 – – – 1.7034 – A 204 Gr. A 15 Mo 3 1501-240 STFA 12 K11820 16 Mo 3 15 D3 16 Mo 3 KW 2912 – – 1.5415 – A 350-LF 5 10 Ni 14 503 SL 3 N 26 K31718 12 Ni 14 12Ni14 18 Ni 14 KT – – – 1.5637 – A 387 Gr. 12 Cl. 2 16 CrMo 4 4 – – K11564 – – A 18 CrMo 4 5 KW – – – 1.7337 – A 570 Gr. 36 St 37–3 4360-40 C – K01501 S 235 J2 G3 Fe 360 D1(2); E 24-3 Fe 360 D1(2) 1312 – – 1.0116 – A 570 Gr. 40 St 44-2 4360-43 B SM 41 B K 02502 S 275 JR E 28-2 Fe 430 BFN 1412 – – 1.0044 – A 570 Gr. 50 St 50-2 4360-50 B SS 50 – E 295 A 50–2 Fe 490 2172 – – 1.0050 – A 573 Gr. 70 St 44-3 4360–43 C SM 41 B – Fe 430 D1(2); S 275 Fe 430 D1(2); E 28-4 Fe 430 D FF 1414 – – 1.0144 – J2 G3 (4) A 633 Gr. C St E 355 P 355 N SM 50 YB K12000 P 355 N E 355 R/FP Fe E 355 KG 2132 – – 1.0562 – A 633 Gr. E St E 420 S 420 N SM 50 C K02002 FeE 420 KGN E 420–I Fe E 420 KG 2143 – – 1.8902 – A 633 Gr. E St E 460 P 460 N SM 53 B K02900 P 460 N E 460–I Fe E 460 KG 2143 – – 1.8905 – A-6 C 67 W – – T30106 – Y1 70 – – – – 1.1744 – E 52100 100 Cr 6 535 A 99 SUJ 2 G52986 100 Cr 6 100 C 6 100 Cr 6 2258 – – 1.3505 – O2 90 MnCrV 8 BO 2 – T31502 90 Mn V 8 90 MV 8 90 MnVCr 8 KU – – – 1.2842 – P21 90 Cr 3 – – T51621 – – – – – – 1.2056 – P3 10 NC 6 – – T51603 15 NiCr 6 10 NC 6 – – – – 1.5713 – P6 15 NiCr 14 – SNC 22 T51606 – 10 NC 12 – – – – 1.2735 – T8 C 80 W2 BW 1B SKC 3 T12008 – Y1 80 C 80 KU – – – 1.1625 – W 108 C 80 W1 – – T72301 C 80 U Y1 90 C 80 KU 1880 – – 1.1525 – W 110 C 105 W1 BW1A – T72301 C 105 U Y 105 C 100 KU 1880 – – 1.1545 – W 112 C 125 W – – – C 125 U – – – – – 1.1563 – W 112 C 125 W – SK 2 T72301 C 120 U Y2 120 C 120 KU – – – 1.1663 – W 210 100 V 1 BW 2 SKS 43 T72302 100 V 2 Y1 105 V 102 V 2 KU – – – 1.2833 – – St 50-1 – – – – – – – – – 1.0052 – – S 235 JO/ Fe 360 C En 40C – – S 235 JO E24-3 Fe 360 CFN – – – 1.0114 – – QSt 37-3 – SWRCH 12R – – – – – – – 1.0123 – – S 275 J0 En43C;S275J0 – – S 275 J0/ Fe 430 C S 275 J0; E 28-3 S275J0; Fe430CFN – – – 1.0143 – – S 275 J2 G4/ Fe 430 D 2 S 275 J2 G4 – – S 275 J2 G4 E28-4; S 275 J2 G4 S 275 J2 G4 1414 – – 1.0145 – – Ro St 44-2 43C – – S 275 J0 H – S 275 J0 H – – – 1.0149 – – St 37.0 – STPG 38 – P 235 T1 – – – – – 1.0254 – – C9D – SWRM 8 – C9D FM 9 C9D – – – 1.0304 – – C7D C7D SWRM 8 G10060 C7D FM 8 C7D – – – 1.0313 – – P235 GH P 235 GH SPV 50 K02503 P 235 GH A 37 CP Fe E 235 1330 – – 1.0345 – – C 25 Pb – – – C 25 GPb – – – – – 1.0411 – – L 245 MB 430 – K03006 L 245 MB L 245 MB – – – – 1.0418 – – P310 NB 224-410 SG 325 K02100 P280GH BS 2 P 275 N 2103 – – 1.0426 – – L 290 MB – – – L290MB L 290 MB – – – – 1.0429 – – H III/P285NH – Sm 38 – P 285 NH – – – – – 1.0435 – – P310 NB 224-430 SG 325 K02100 P305GH P 275 N P 275 N 2103 – – 1.0436 – – A St 41 P 275 N STK 400 K02100 S 275 N BS 3 P 275 N 2103 – – 1.0437 – – B 500 A – SD 490 – B 500 A – B 500 A – – – 1.0438 – – H IV/P295NH – SG 37 K03102 – – Fe 460-2 KW – – – 1.0445 – – StE 240.7 – – – L 245 NB L 245 NB – – – – 1.0457 – – TStE 255 – – K11535 – – – – – – 1.0463 – – 15 Mn 3 Al – – – C 14 GAl – – – – – 1.0468 – – 19 Mn 6/P 355 GH P 355 GH SGV 46 K03300 P355GH A 52 CP Fe E355–2 2101 – – 1.0473 – – 17 Mn 4/P 295 GH 224–460B SG 37 K03501 P 295 GH A 48 CP Fe E 295 2102 – – 1.0481 – – 19 Mn 5 224-460 SG 37 K 03102 – A 52 CP; AP; FP Fe 460- 2 KW – – – 1.0482 – – L 290 AG – – – L290GA TS E 290 – – – – 1.0483 – – L 290 NB – – – L290NB L 290 NB – – – – 1.0484 – – 21 Mn 6 – – K12320 – – – – – – 1.0485 – – St E 285 P 275 N SM 41 A K 01802 P 275 N P 275 N Fe E 285 KG – – – 1.0486 – – W St E 285 P 275 N – K 01802 P 275 NH P 275 N Fe E 285 KW – – – 1.0487 – – T St E 285 P 275 NL 1 SLA 235 A K 01803 P 275 NL 1 P 275 NL 1 Fe E 285 KT – – – 1.0488 – – H 300/ZSt E 300 H280LA – – H 280 LA E 280 C – – – – 1.0489 – – S 275 NH S 275 NH – – S 275 NH – S 275 NH – – – 1.0493 – – S 275 NLH S275NLH – – S 275 NLH – S275NLH – – – 1.0497 – – C 35 Pb/C 35 GPb – – – C 35 Pb – – – – – 1.0502 – – St E 315/P 315N – SM 50 A K11506 P 315 N – Fe E 315 KG – – – 1.0505 – – W St E 315 – SNC 1 K02404 P 315 NH – Fe E 315 KW 2107 – – 1.0506 – – St 55 – STKM 16A – – – Fe 540 – – – 1.0507 – – T St E315 – SLA 325 A K02404 P 315 NL – – 2106 – – 1.0508 – – C 40 Pb – – – C 40 G Pb – – – – – 1.0512 – – C38D – SWRH 37 – C 38 D FM 38 C 38 D – – – 1.0516 – – C48D – SWRH 48 – C 48 D FM 48 C 48 D – – – 1.0517 – – C56D – – – C 56 D FM 56 C 56 D – – – 1.0518 – – S 355 NH S 355 NH – – S 355 NH – S 355 NH – – – 1.0539 – – C42D – SWRH 42 B – C 42 D FM 42 C 42 D – – – 1.0541 – – S 355 JO H 50 C – – S 355 J0 H – S 355 J0 H – – – 1.0547 – – ZStE 340/ H 340 H 320 L A – – H 320 LA E 315 C – – – – 1.0548 – – S 335 NLH 50 EE – – S 355 N LH – S 355 N L H – – – 1.0549 – – S 355 JO En 50 C; S 355 J0 SM 520 M – S 355 J0 S 355 J0; E 36-3 S 355 J0; Fe 510 C FN – – – 1.0553 – – GS-70 50 C – – S 355 JO C E 36–3 Fe 510 C – – – 1.0554 – Y194 (продолжение)

Каталог Kennametal инновации 2021.1

Каталог Kennametal инновации 2021.1 Каталог Kennametal инновации 2022.2

Каталог Kennametal инновации 2022.2 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1