Каталог Iscar вращающийся инструмент 2017 - страница 585

Навигация

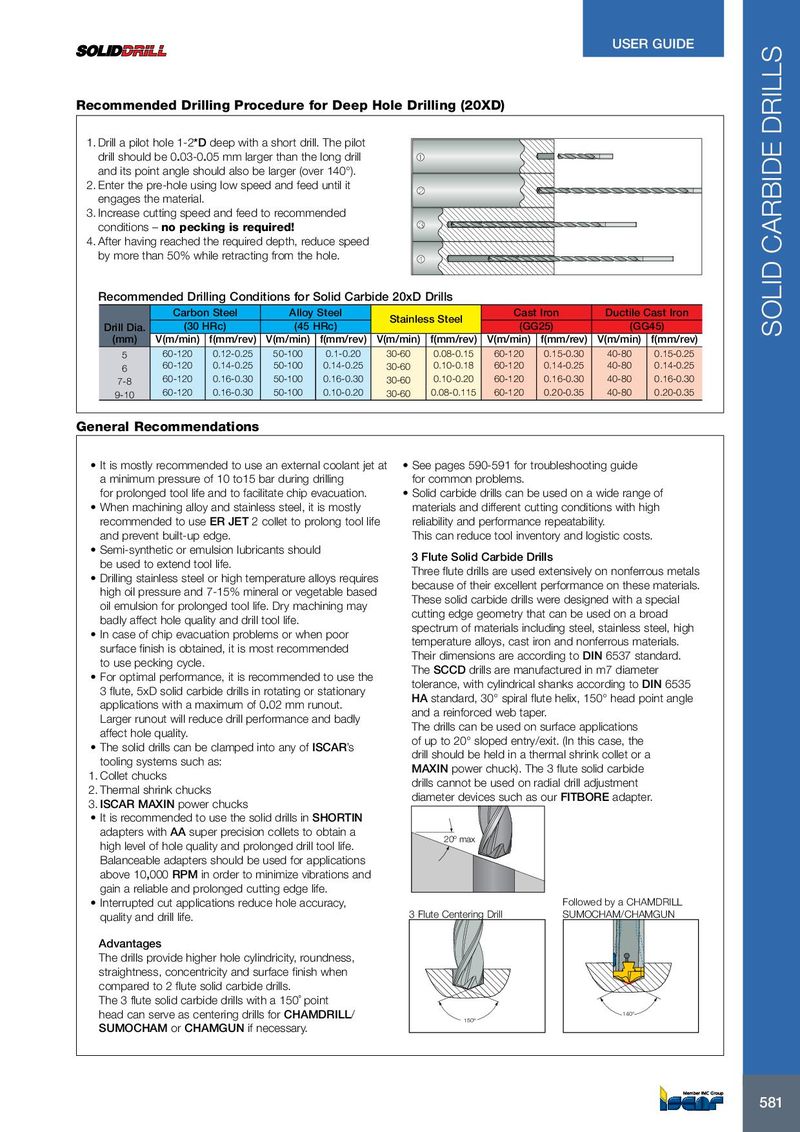

USER GUIDE Recommended Drilling Procedure for Deep Hole Drilling (20XD) 1. Drill a pilot hole 1-2*D deep with a short drill. The pilot drill should be 0.03-0.05 mm larger than the long drill 1 and its point angle should also be larger (over 140°). 2. Enter the pre-hole using low speed and feed until it 2 engages the material. 3. Increase cutting speed and feed to recommended conditions – no pecking is required! 3 4. After having reached the required depth, reduce speed by more than 50% while retracting from the hole. 4 Recommended Drilling Conditions for Solid Carbide 20xD Drills Carbon Steel Alloy Steel Cast Iron Ductile Cast Iron Stainless Steel Drill Dia. (30 HRc) (45 HRc) (GG25) (GG45) SOLID CARBIDE DRILLS (mm) V(m/min) f(mm/rev) V(m/min) f(mm/rev) V(m/min) f(mm/rev) V(m/min) f(mm/rev) V(m/min) f(mm/rev) 5 60-120 0.12-0.25 50-100 0.1-0.20 30-60 0.08-0.15 60-120 0.15-0.30 40-80 0.15-0.25 6 60-120 0.14-0.25 50-100 0.14-0.25 30-60 0.10-0.18 60-120 0.14-0.25 40-80 0.14-0.25 7-8 60-120 0.16-0.30 50-100 0.16-0.30 30-60 0.10-0.20 60-120 0.16-0.30 40-80 0.16-0.30 9-10 60-120 0.16-0.30 50-100 0.10-0.20 30-60 0.08-0.115 60-120 0.20-0.35 40-80 0.20-0.35 General Recommendations • It is mostly recommended to use an external coolant jet at • See pages 590-591 for troubleshooting guide a minimum pressure of 10 to15 bar during drilling for common problems. for prolonged tool life and to facilitate chip evacuation. • Solid carbide drills can be used on a wide range of • When machining alloy and stainless steel, it is mostly materials and different cutting conditions with high recommended to use ER JET 2 collet to prolong tool life reliability and performance repeatability. and prevent built-up edge. This can reduce tool inventory and logistic costs. • Semi-synthetic or emulsion lubricants should 3 Flute Solid Carbide Drills be used to extend tool life. Three flute drills are used extensively on nonferrous metals • Drilling stainless steel or high temperature alloys requires because of their excellent performance on these materials. high oil pressure and 7-15% mineral or vegetable based These solid carbide drills were designed with a special oil emulsion for prolonged tool life. Dry machining may cutting edge geometry that can be used on a broad badly affect hole quality and drill tool life. spectrum of materials including steel, stainless steel, high • In case of chip evacuation problems or when poor temperature alloys, cast iron and nonferrous materials. surface finish is obtained, it is most recommended Their dimensions are according to DIN 6537 standard. to use pecking cycle. The SCCD drills are manufactured in m7 diameter • For optimal performance, it is recommended to use the tolerance, with cylindrical shanks according to DIN 6535 3 flute, 5xD solid carbide drills in rotating or stationary HA standard, 30° spiral flute helix, 150° head point angle applications with a maximum of 0.02 mm runout. and a reinforced web taper. Larger runout will reduce drill performance and badly The drills can be used on surface applications affect hole quality. of up to 20° sloped entry/exit. (In this case, the • The solid drills can be clamped into any of ISCAR’s drill should be held in a thermal shrink collet or a tooling systems such as: MAXIN power chuck). The 3 flute solid carbide 1. Collet chucks drills cannot be used on radial drill adjustment 2. Thermal shrink chucks diameter devices such as our FITBORE adapter. 3. ISCAR MAXIN power chucks • It is recommended to use the solid drills in SHORTIN adapters with AA super precision collets to obtain a 20º max high level of hole quality and prolonged drill tool life. Balanceable adapters should be used for applications above 10,000 RPM in order to minimize vibrations and gain a reliable and prolonged cutting edge life. • Interrupted cut applications reduce hole accuracy, Followed by a CHAMDRILL quality and drill life. 3 Flute Centering Drill SUMOCHAM/CHAMGUN Advantages The drills provide higher hole cylindricity, roundness, straightness, concentricity and surface finish when compared to 2 flute solid carbide drills. The 3 flute solid carbide drills with a 150˚ point head can serve as centering drills for CHAMDRILL/ 140° 150º SUMOCHAM or CHAMGUN if necessary. 581 581

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022