Каталог Iscar вращающийся инструмент 2017 - страница 581

Навигация

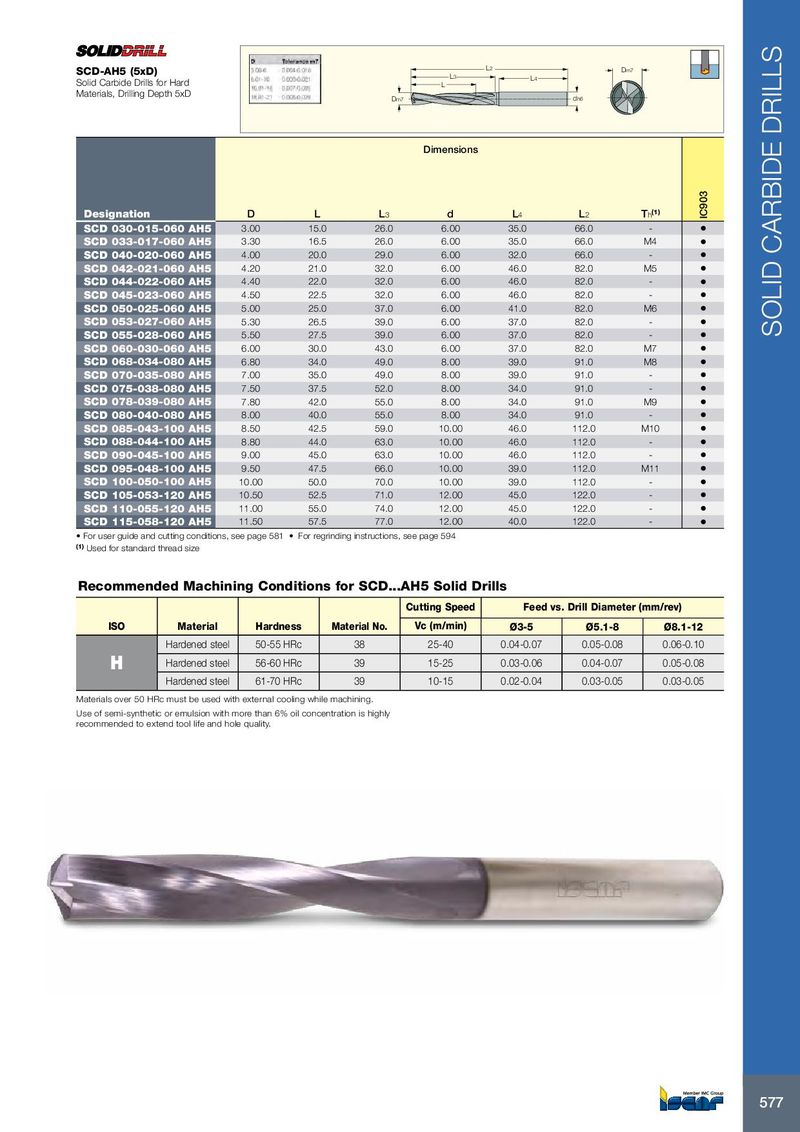

L2 SCD-AH5 (5xD) Dm7 L3 L4 Solid Carbide Drills for Hard L Materials, Drilling Depth 5xD Dm7 dh6 Dimensions Designation D L L 3 d L 4 L 2 T h (1) IC903 SCD 030-015-060 AH5 3.00 15.0 26.0 6.00 35.0 66.0 - • SCD 033-017-060 AH5 3.30 16.5 26.0 6.00 35.0 66.0 M4 • SCD 040-020-060 AH5 4.00 20.0 29.0 6.00 32.0 66.0 - • SCD 042-021-060 AH5 4.20 21.0 32.0 6.00 46.0 82.0 M5 • SCD 044-022-060 AH5 4.40 22.0 32.0 6.00 46.0 82.0 - • SCD 045-023-060 AH5 4.50 22.5 32.0 6.00 46.0 82.0 - • SCD 050-025-060 AH5 5.00 25.0 37.0 6.00 41.0 82.0 M6 • SCD 053-027-060 AH5 5.30 26.5 39.0 6.00 37.0 82.0 - • SCD 055-028-060 AH5 5.50 27.5 39.0 6.00 37.0 82.0 - • SOLID CARBIDE DRILLS SCD 060-030-060 AH5 6.00 30.0 43.0 6.00 37.0 82.0 M7 • SCD 068-034-080 AH5 6.80 34.0 49.0 8.00 39.0 91.0 M8 • SCD 070-035-080 AH5 7.00 35.0 49.0 8.00 39.0 91.0 - • SCD 075-038-080 AH5 7.50 37.5 52.0 8.00 34.0 91.0 - • SCD 078-039-080 AH5 7.80 42.0 55.0 8.00 34.0 91.0 M9 • SCD 080-040-080 AH5 8.00 40.0 55.0 8.00 34.0 91.0 - • SCD 085-043-100 AH5 8.50 42.5 59.0 10.00 46.0 112.0 M10 • SCD 088-044-100 AH5 8.80 44.0 63.0 10.00 46.0 112.0 - • SCD 090-045-100 AH5 9.00 45.0 63.0 10.00 46.0 112.0 - • SCD 095-048-100 AH5 9.50 47.5 66.0 10.00 39.0 112.0 M11 • SCD 100-050-100 AH5 10.00 50.0 70.0 10.00 39.0 112.0 - • SCD 105-053-120 AH5 10.50 52.5 71.0 12.00 45.0 122.0 - • SCD 110-055-120 AH5 11.00 55.0 74.0 12.00 45.0 122.0 - • SCD 115-058-120 AH5 11.50 57.5 77.0 12.00 40.0 122.0 - • • For user guide and cutting conditions, see page 581 • For regrinding instructions, see page 594 (1) Used for standard thread size Recommended Machining Conditions for SCD...AH5 Solid Drills Cutting Speed Feed vs. Drill Diameter (mm/rev) ISO Material Hardness Material No. Vc (m/min) Ø3-5 Ø5.1-8 Ø8.1-12 Hardened steel 50-55 HRc 38 25-40 0.04-0.07 0.05-0.08 0.06-0.10 H Hardened steel 56-60 HRc 39 15-25 0.03-0.06 0.04-0.07 0.05-0.08 Hardened steel 61-70 HRc 39 10-15 0.02-0.04 0.03-0.05 0.03-0.05 Materials over 50 HRc must be used with external cooling while machining. Use of semi-synthetic or emulsion with more than 6% oil concentration is highly recommended to extend tool life and hole quality. 577

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022