Каталог Iscar вращающийся инструмент 2017 - страница 279

Навигация

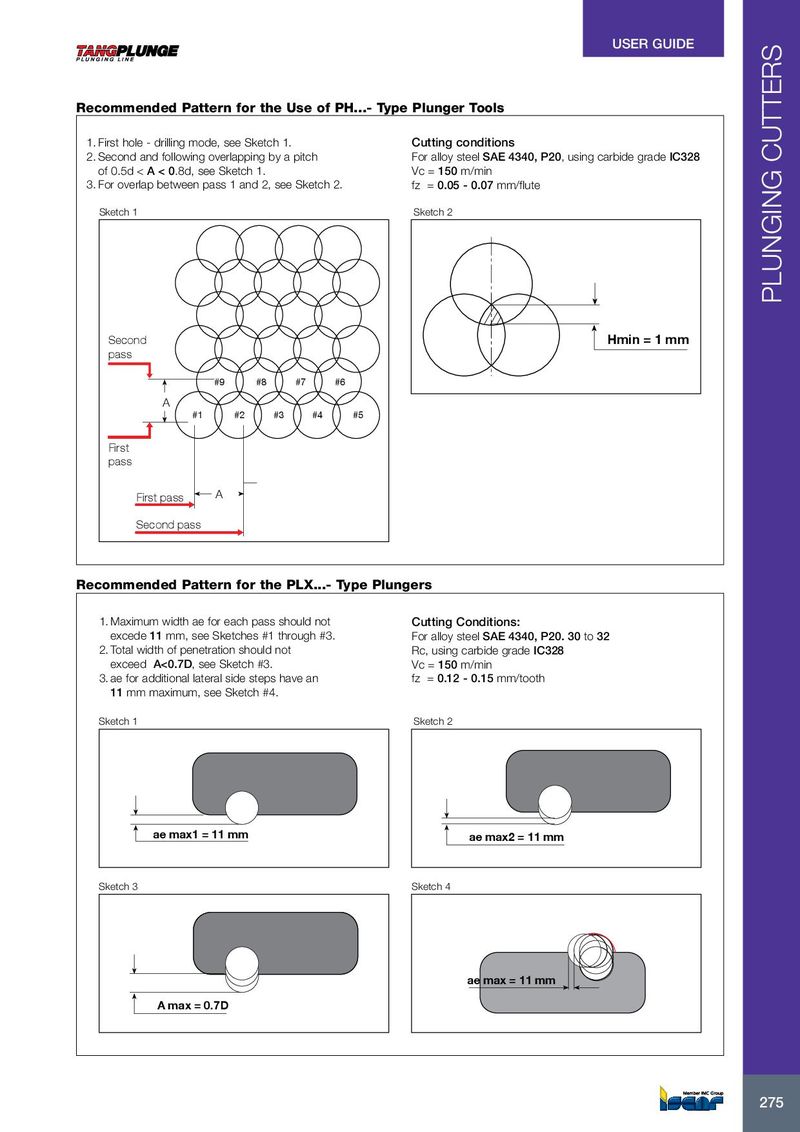

USER GUIDE Recommended Pattern for the Use of PH...- Type Plunger Tools 1. First hole - drilling mode, see Sketch 1. Cutting conditions 2. Second and following overlapping by a pitch For alloy steel SAE 4340, P20, using carbide grade IC328 of 0.5d < A < 0.8d, see Sketch 1. Vc = 150 m/min 3. For overlap between pass 1 and 2, see Sketch 2. fz = 0.05 - 0.07 mm/flute Sketch 1 Sketch 2 PLUNGING CUTTERS Second Hmin = 1 mm pass #9 #8 #7 #6 A #1 #2 #3 #4 #5 First pass First pass A Second pass Recommended Pattern for the PLX...- Type Plungers 1. Maximum width ae for each pass should not Cutting Conditions: excede 11 mm, see Sketches #1 through #3. For alloy steel SAE 4340, P20. 30 to 32 2. Total width of penetration should not Rc, using carbide grade IC328 exceed A<0.7D, see Sketch #3. Vc = 150 m/min 3. ae for additional lateral side steps have an fz = 0.12 - 0.15 mm/tooth 11 mm maximum, see Sketch #4. Sketch 1 Sketch 2 ae max1 = 11 mm ae max2 = 11 mm Sketch 3 Sketch 4 Dt Di ae max = 11 mm A max = 0.7D 275 275

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022