Каталог Iscar вращающийся инструмент 2017 - страница 276

Навигация

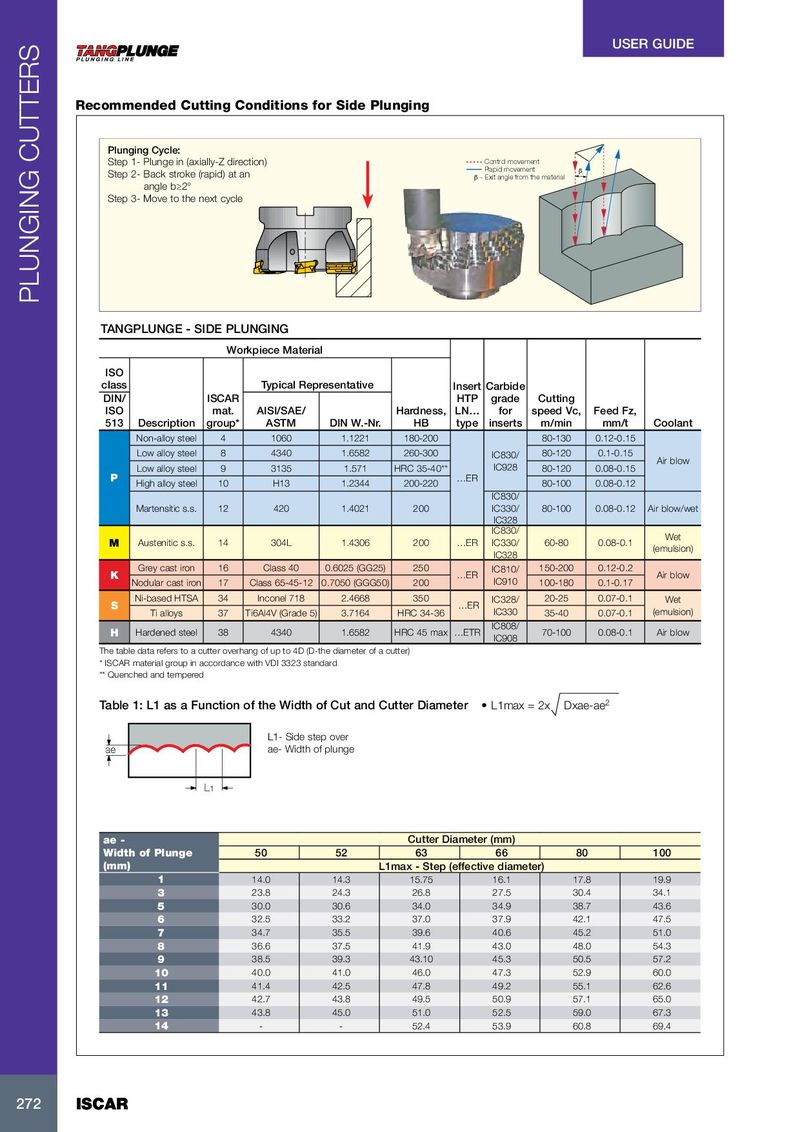

USER GUIDE Recommended Cutting Conditions for Side Plunging Plunging Cycle: Step 1- Plunge in (axially-Z direction) Control movement Rapid movement β Step 2- Back stroke (rapid) at an β - Exit angle from the material angle b≥2° Step 3- Move to the next cycle PLUNGING CUTTERS TANGPLUNGE - SIDE PLUNGING Workpiece Material ISO class Typical Representative Insert Carbide DIN/ ISCAR HTP grade Cutting ISO mat. AISI/SAE/ Hardness, LN… for speed Vc, Feed Fz, 513 Description group* ASTM DIN W.-Nr. HB type inserts m/min mm/t Coolant Non-alloy steel 4 1060 1.1221 180-200 80-130 0.12-0.15 Low alloy steel 8 4340 1.6582 260-300 IC830/ 80-120 0.1-0.15 Air blow Low alloy steel 9 3135 1.571 HRC 35-40** IC928 80-120 0.08-0.15 P …ER High alloy steel 10 H13 1.2344 200-220 80-100 0.08-0.12 IC830/ Martensitic s.s. 12 420 1.4021 200 IC330/ 80-100 0.08-0.12 Air blow/wet IC328 IC830/ Wet M Austenitic s.s. 14 304L 1.4306 200 …ER IC330/ 60-80 0.08-0.1 (emulsion) IC328 Grey cast iron 16 Class 40 0.6025 (GG25) 250 IC810/ 150-200 0.12-0.2 K …ER Air blow Nodular cast iron 17 Class 65-45-12 0.7050 (GGG50) 200 IC910 100-180 0.1-0.17 Ni-based HTSA 34 Inconel 718 2.4668 350 IC328/ 20-25 0.07-0.1 Wet S …ER Ti alloys 37 Ti6Al4V (Grade 5) 3.7164 HRC 34-36 IC330 35-40 0.07-0.1 (emulsion) IC808/ H Hardened steel 38 4340 1.6582 HRC 45 max …ETR 70-100 0.08-0.1 Air blow IC908 The table data refers to a cutter overhang of up to 4D (D-the diameter of a cutter) * ISCAR material group in accordance with VDI 3323 standard ** Quenched and tempered Table 1: L1 as a Function of the Width of Cut and Cutter Diameter • L1max = 2x Dxae-ae 2 L1- Side step over ae ae- Width of plunge L1 ae - Cutter Diameter (mm) Width of Plunge 50 52 63 66 80 100 (mm) L1max - Step (effective diameter) 1 14.0 14.3 15.75 16.1 17.8 19.9 3 23.8 24.3 26.8 27.5 30.4 34.1 5 30.0 30.6 34.0 34.9 38.7 43.6 6 32.5 33.2 37.0 37.9 42.1 47.5 7 34.7 35.5 39.6 40.6 45.2 51.0 8 36.6 37.5 41.9 43.0 48.0 54.3 9 38.5 39.3 43.10 45.3 50.5 57.2 10 40.0 41.0 46.0 47.3 52.9 60.0 11 41.4 42.5 47.8 49.2 55.1 62.6 12 42.7 43.8 49.5 50.9 57.1 65.0 13 43.8 45.0 51.0 52.5 59.0 67.3 14 - - 52.4 53.9 60.8 69.4 272 272 ISCAR ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022