Каталог Iscar вращающийся инструмент 2017 - страница 236

Навигация

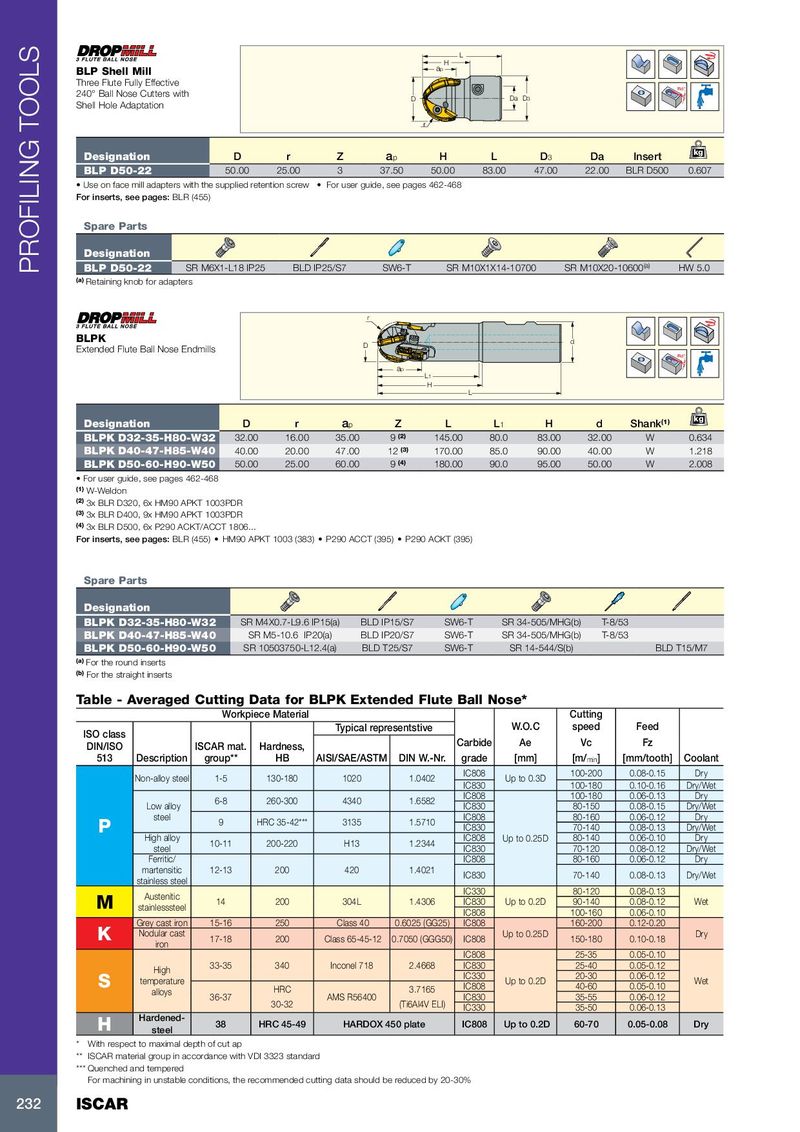

L H BLP Shell Mill ap Three Flute Fully Effective Rd° 240° Ball Nose Cutters with D Da D3 Shell Hole Adaptation r kg Designation D r Z a p H L D 3 Da Insert BLP D50-22 50.00 25.00 3 37.50 50.00 83.00 47.00 22.00 BLR D500 0.607 • Use on face mill adapters with the supplied retention screw • For user guide, see pages 462-468 For inserts, see pages: BLR (455) Spare Parts Designation PROFILING TOOLS BLP D50-22 SR M6X1-L18 IP25 BLD IP25/S7 SW6-T SR M10X1X14-10700 SR M10X20-10600 (a) HW 5.0 (a) Retaining knob for adapters r BLPK D d Extended Flute Ball Nose Endmills Rd° ap L1 H L Designation D r a p Z L L 1 H d Shank (1) kg BLPK D32-35-H80-W32 32.00 16.00 35.00 9 (2) 145.00 80.0 83.00 32.00 W 0.634 BLPK D40-47-H85-W40 40.00 20.00 47.00 12 (3) 170.00 85.0 90.00 40.00 W 1.218 BLPK D50-60-H90-W50 50.00 25.00 60.00 9 (4) 180.00 90.0 95.00 50.00 W 2.008 • For user guide, see pages 462-468 (1) W-Weldon (2) 3x BLR D320, 6x HM90 APKT 1003PDR (3) 3x BLR D400, 9x HM90 APKT 1003PDR (4) 3x BLR D500, 6x P290 ACKT/ACCT 1806... For inserts, see pages: BLR (455) • HM90 APKT 1003 (383) • P290 ACCT (395) • P290 ACKT (395) Spare Parts Designation BLPK D32-35-H80-W32 SR M4X0.7-L9.6 IP15(a) BLD IP15/S7 SW6-T SR 34-505/MHG(b) T-8/53 BLPK D40-47-H85-W40 SR M5-10.6 IP20(a) BLD IP20/S7 SW6-T SR 34-505/MHG(b) T-8/53 BLPK D50-60-H90-W50 SR 10503750-L12.4(a) BLD T25/S7 SW6-T SR 14-544/S(b) BLD T15/M7 (a) For the round inserts (b) For the straight inserts Table - Averaged Cutting Data for BLPK Extended Flute Ball Nose* Workpiece Material Cutting Typical representstive W.O.C speed Feed ISO class DIN/ISO ISCAR mat. Hardness, Carbide Ae Vc Fz 513 Description group** HB AISI/SAE/ASTM DIN W.-Nr. grade [mm] [m/ min ] [mm/tooth] Coolant IC808 100-200 0.08-0.15 Dry Non-alloy steel 1-5 130-180 1020 1.0402 Up to 0.3D IC830 100-180 0.10-0.16 Dry/Wet IC808 100-180 0.06-0.13 Dry 6-8 260-300 4340 1.6582 Low alloy IC830 80-150 0.08-0.15 Dry/Wet steel IC808 80-160 0.06-0.12 Dry 9 HRC 35-42*** 3135 1.5710 P IC830 70-140 0.08-0.13 Dry/Wet High alloy IC808 Up to 0.25D 80-140 0.06-0.10 Dry 10-11 200-220 H13 1.2344 steel IC830 70-120 0.08-0.12 Dry/Wet Ferritic/ IC808 80-160 0.06-0.12 Dry martensitic 12-13 200 420 1.4021 IC830 70-140 0.08-0.13 Dry/Wet stainless steel IC330 80-120 0.08-0.13 Austenitic M 14 200 304L 1.4306 IC830 Up to 0.2D 90-140 0.08-0.12 Wet stainlesssteel IC808 100-160 0.06-0.10 Grey cast iron 15-16 250 Class 40 0.6025 (GG25) IC808 160-200 0.12-0.20 K Nodular cast Up to 0.25D Dry 17-18 200 Class 65-45-12 0.7050 (GGG50) IC808 150-180 0.10-0.18 iron IC808 25-35 0.05-0.10 33-35 340 Inconel 718 2.4668 IC830 25-40 0.05-0.12 High IC330 20-30 0.06-0.12 S temperature Up to 0.2D Wet alloys HRC 3.7165 IC808 40-60 0.05-0.10 36-37 AMS R56400 IC830 35-55 0.06-0.12 30-32 (Ti6Al4V ELI) IC330 35-50 0.06-0.13 Hardened- H 38 HRC 45-49 HARDOX 450 plate IC808 Up to 0.2D 60-70 0.05-0.08 Dry steel * With respect to maximal depth of cut ap ** ISCAR material group in accordance with VDI 3323 standard *** Quenched and tempered For machining in unstable conditions, the recommended cutting data should be reduced by 20-30% 232 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022