Каталог Iscar вращающийся инструмент 2017 - страница 140

Навигация

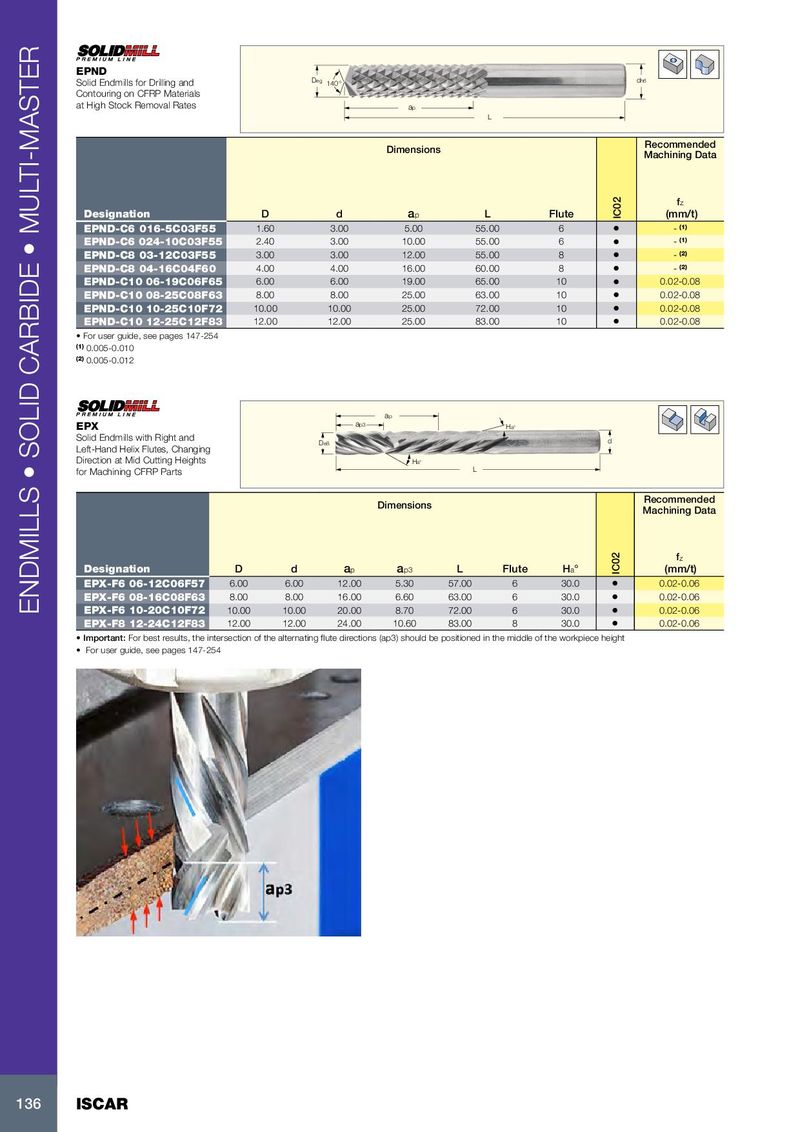

EPND Solid Endmills for Drilling and Deg 140° dh6 Contouring on CFRP Materials at High Stock Removal Rates ap L Recommended Dimensions Machining Data f z Designation D d a p L Flute IC02 (mm/t) EPND-C6 016-5C03F55 1.60 3.00 5.00 55.00 6 (1) • - EPND-C6 024-10C03F55 2.40 3.00 10.00 55.00 6 • - (1) EPND-C8 03-12C03F55 3.00 3.00 12.00 55.00 8 (2) • - EPND-C8 04-16C04F60 4.00 4.00 16.00 60.00 8 • - (2) EPND-C10 06-19C06F65 6.00 6.00 19.00 65.00 10 • 0.02-0.08 EPND-C10 08-25C08F63 8.00 8.00 25.00 63.00 10 • 0.02-0.08 EPND-C10 10-25C10F72 10.00 10.00 25.00 72.00 10 • 0.02-0.08 EPND-C10 12-25C12F83 12.00 12.00 25.00 83.00 10 • 0.02-0.08 • For user guide, see pages 147-254 (1) 0.005-0.010 (2) 0.005-0.012 ap EPX ap3 Ha° Solid Endmills with Right and De8 d Left-Hand Helix Flutes, Changing Direction at Mid Cutting Heights Ha° for Machining CFRP Parts L Recommended Dimensions Machining Data f z Designation D d a p a p3 L Flute H a ° IC02 (mm/t) EPX-F6 06-12C06F57 6.00 6.00 12.00 5.30 57.00 6 30.0 • 0.02-0.06 EPX-F6 08-16C08F63 8.00 8.00 16.00 6.60 63.00 6 30.0 • 0.02-0.06 ENDMILLS • SOLID CARBIDE • MULTI-MASTER EPX-F6 10-20C10F72 10.00 10.00 20.00 8.70 72.00 6 30.0 • 0.02-0.06 EPX-F8 12-24C12F83 12.00 12.00 24.00 10.60 83.00 8 30.0 • 0.02-0.06 • Important: For best results, the intersection of the alternating flute directions (ap3) should be positioned in the middle of the workpiece height • For user guide, see pages 147-254 136 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022