Каталог Iscar токарный инструмент 2017 - страница 379

Навигация

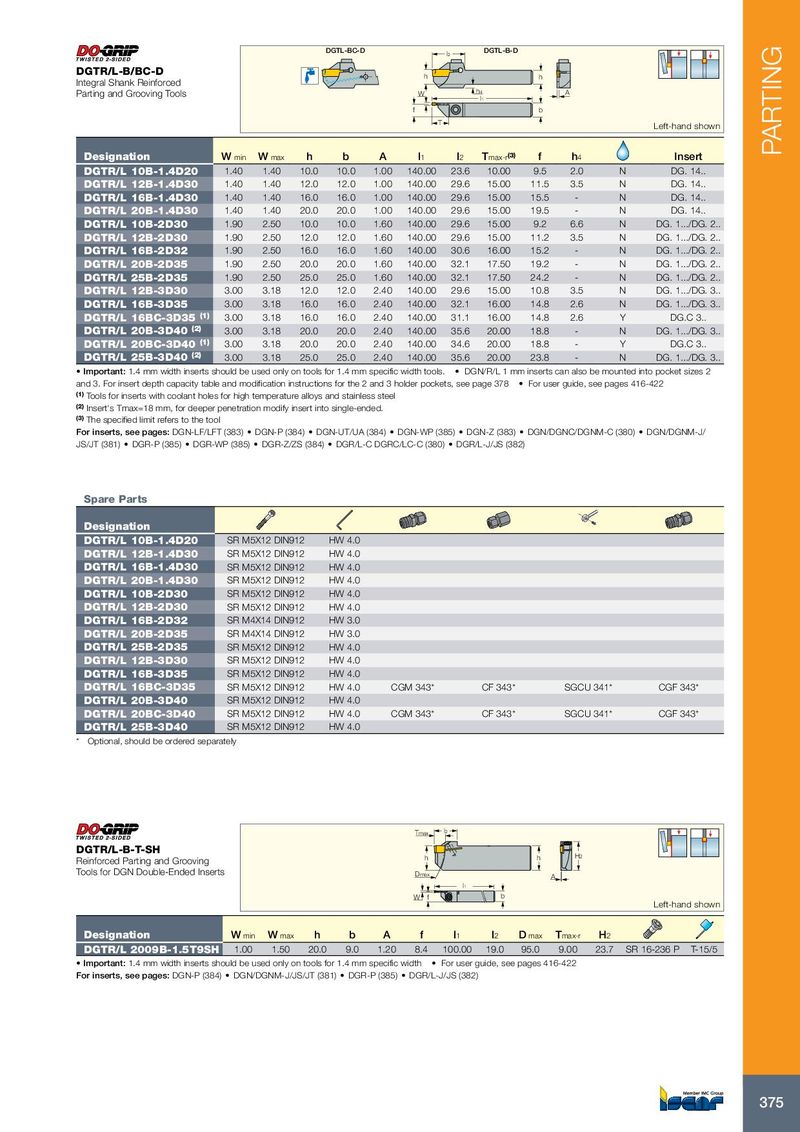

DGTL-BC-D l2 DGTL-B-D DGTR/L-B/BC-D h h Integral Shank Reinforced Parting and Grooving Tools W h4 A l1 f b T Left-hand shown PARTING Designation W min W max h b A l 1 l 2 T max-r (3) f h 4 Insert DGTR/L 10B-1.4D20 1.40 1.40 10.0 10.0 1.00 140.00 23.6 10.00 9.5 2.0 N DG. 14.. DGTR/L 12B-1.4D30 1.40 1.40 12.0 12.0 1.00 140.00 29.6 15.00 11.5 3.5 N DG. 14.. DGTR/L 16B-1.4D30 1.40 1.40 16.0 16.0 1.00 140.00 29.6 15.00 15.5 - N DG. 14.. DGTR/L 20B-1.4D30 1.40 1.40 20.0 20.0 1.00 140.00 29.6 15.00 19.5 - N DG. 14.. DGTR/L 10B-2D30 1.90 2.50 10.0 10.0 1.60 140.00 29.6 15.00 9.2 6.6 N DG. 1.../DG. 2.. DGTR/L 12B-2D30 1.90 2.50 12.0 12.0 1.60 140.00 29.6 15.00 11.2 3.5 N DG. 1.../DG. 2.. DGTR/L 16B-2D32 1.90 2.50 16.0 16.0 1.60 140.00 30.6 16.00 15.2 - N DG. 1.../DG. 2.. DGTR/L 20B-2D35 1.90 2.50 20.0 20.0 1.60 140.00 32.1 17.50 19.2 - N DG. 1.../DG. 2.. DGTR/L 25B-2D35 1.90 2.50 25.0 25.0 1.60 140.00 32.1 17.50 24.2 - N DG. 1.../DG. 2.. DGTR/L 12B-3D30 3.00 3.18 12.0 12.0 2.40 140.00 29.6 15.00 10.8 3.5 N DG. 1.../DG. 3.. DGTR/L 16B-3D35 3.00 3.18 16.0 16.0 2.40 140.00 32.1 16.00 14.8 2.6 N DG. 1.../DG. 3.. DGTR/L 16BC-3D35 (1) 3.00 3.18 16.0 16.0 2.40 140.00 31.1 16.00 14.8 2.6 Y DG.C 3.. DGTR/L 20B-3D40 (2) 3.00 3.18 20.0 20.0 2.40 140.00 35.6 20.00 18.8 - N DG. 1.../DG. 3.. DGTR/L 20BC-3D40 (1) 3.00 3.18 20.0 20.0 2.40 140.00 34.6 20.00 18.8 - Y DG.C 3.. DGTR/L 25B-3D40 (2) 3.00 3.18 25.0 25.0 2.40 140.00 35.6 20.00 23.8 - N DG. 1.../DG. 3.. • Important: 1.4 mm width inserts should be used only on tools for 1.4 mm specific width tools. • DGN/R/L 1 mm inserts can also be mounted into pocket sizes 2 and 3. For insert depth capacity table and modification instructions for the 2 and 3 holder pockets, see page 378 • For user guide, see pages 416-422 (1) Tools for inserts with coolant holes for high temperature alloys and stainless steel (2) Insert's Tmax=18 mm, for deeper penetration modify insert into single-ended. (3) The specified limit refers to the tool For inserts, see pages: DGN-LF/LFT (383) • DGN-P (384) • DGN-UT/UA (384) • DGN-WP (385) • DGN-Z (383) • DGN/DGNC/DGNM-C (380) • DGN/DGNM-J/ JS/JT (381) • DGR-P (385) • DGR-WP (385) • DGR-Z/ZS (384) • DGR/L-C DGRC/LC-C (380) • DGR/L-J/JS (382) Spare Parts Designation DGTR/L 10B-1.4D20 SR M5X12 DIN912 HW 4.0 DGTR/L 12B-1.4D30 SR M5X12 DIN912 HW 4.0 DGTR/L 16B-1.4D30 SR M5X12 DIN912 HW 4.0 DGTR/L 20B-1.4D30 SR M5X12 DIN912 HW 4.0 DGTR/L 10B-2D30 SR M5X12 DIN912 HW 4.0 DGTR/L 12B-2D30 SR M5X12 DIN912 HW 4.0 DGTR/L 16B-2D32 SR M4X14 DIN912 HW 3.0 DGTR/L 20B-2D35 SR M4X14 DIN912 HW 3.0 DGTR/L 25B-2D35 SR M5X12 DIN912 HW 4.0 DGTR/L 12B-3D30 SR M5X12 DIN912 HW 4.0 DGTR/L 16B-3D35 SR M5X12 DIN912 HW 4.0 DGTR/L 16BC-3D35 SR M5X12 DIN912 HW 4.0 CGM 343* CF 343* SGCU 341* CGF 343* DGTR/L 20B-3D40 SR M5X12 DIN912 HW 4.0 DGTR/L 20BC-3D40 SR M5X12 DIN912 HW 4.0 CGM 343* CF 343* SGCU 341* CGF 343* DGTR/L 25B-3D40 SR M5X12 DIN912 HW 4.0 * Optional, should be ordered separately Tmax l2 DGTR/L-B-T-SH h h H2 Reinforced Parting and Grooving Tools for DGN Double-Ended Inserts Dmax A l1 W f b Left-hand shown Designation W min W max h b A f l 1 l 2 D max T max-r H 2 DGTR/L 2009B-1.5T9SH 1.00 1.50 20.0 9.0 1.20 8.4 100.00 19.0 95.0 9.00 23.7 SR 16-236 P T-15/5 • Important: 1.4 mm width inserts should be used only on tools for 1.4 mm specific width • For user guide, see pages 416-422 For inserts, see pages: DGN-P (384) • DGN/DGNM-J/JS/JT (381) • DGR-P (385) • DGR/L-J/JS (382) 375

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017