Каталог Iscar токарный инструмент 2017 - страница 378

Навигация

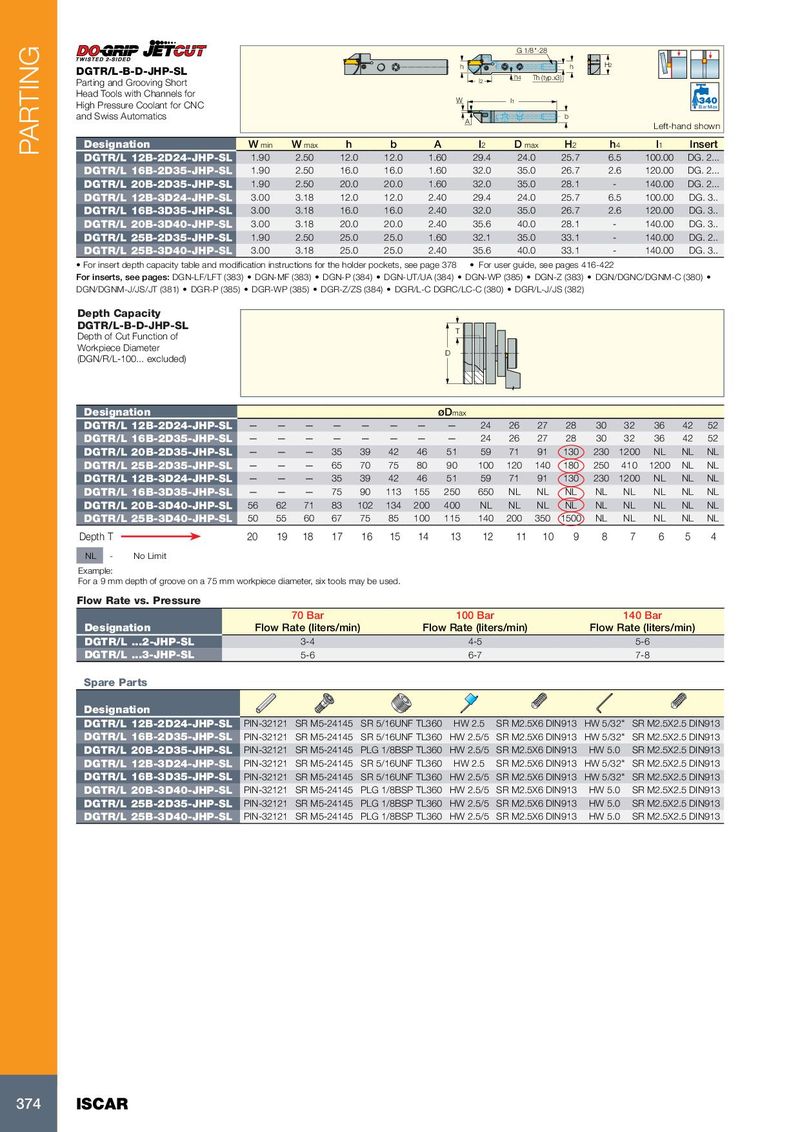

G 1/8"-28 h h H2 DGTR/L-B-D-JHP-SL Parting and Grooving Short l2 h4 Th (typ.x3) Head Tools with Channels for W l1 High Pressure Coolant for CNC Bar Max and Swiss Automatics b A Left-hand shown Designation W min W max h b A l 2 D max H 2 h 4 l 1 Insert PARTING DGTR/L 12B-2D24-JHP-SL 1.90 2.50 12.0 12.0 1.60 29.4 24.0 25.7 6.5 100.00 DG. 2... DGTR/L 16B-2D35-JHP-SL 1.90 2.50 16.0 16.0 1.60 32.0 35.0 26.7 2.6 120.00 DG. 2... DGTR/L 20B-2D35-JHP-SL 1.90 2.50 20.0 20.0 1.60 32.0 35.0 28.1 - 140.00 DG. 2... DGTR/L 12B-3D24-JHP-SL 3.00 3.18 12.0 12.0 2.40 29.4 24.0 25.7 6.5 100.00 DG. 3.. DGTR/L 16B-3D35-JHP-SL 3.00 3.18 16.0 16.0 2.40 32.0 35.0 26.7 2.6 120.00 DG. 3.. DGTR/L 20B-3D40-JHP-SL 3.00 3.18 20.0 20.0 2.40 35.6 40.0 28.1 - 140.00 DG. 3.. DGTR/L 25B-2D35-JHP-SL 1.90 2.50 25.0 25.0 1.60 32.1 35.0 33.1 - 140.00 DG. 2.. DGTR/L 25B-3D40-JHP-SL 3.00 3.18 25.0 25.0 2.40 35.6 40.0 33.1 - 140.00 DG. 3.. • For insert depth capacity table and modification instructions for the holder pockets, see page 378 • For user guide, see pages 416-422 For inserts, see pages: DGN-LF/LFT (383) • DGN-MF (383) • DGN-P (384) • DGN-UT/UA (384) • DGN-WP (385) • DGN-Z (383) • DGN/DGNC/DGNM-C (380) • DGN/DGNM-J/JS/JT (381) • DGR-P (385) • DGR-WP (385) • DGR-Z/ZS (384) • DGR/L-C DGRC/LC-C (380) • DGR/L-J/JS (382) Depth Capacity DGTR/L-B-D-JHP-SL T Depth of Cut Function of Workpiece Diameter D (DGN/R/L-100... excluded) Designation øD max DGTR/L 12B-2D24-JHP-SL — — — — — — — — 24 26 27 28 30 32 36 42 52 DGTR/L 16B-2D35-JHP-SL — — — — — — — — 24 26 27 28 30 32 36 42 52 DGTR/L 20B-2D35-JHP-SL — — — 35 39 42 46 51 59 71 91 130 230 1200 NL NL NL DGTR/L 25B-2D35-JHP-SL — — — 65 70 75 80 90 100 120 140 180 250 410 1200 NL NL DGTR/L 12B-3D24-JHP-SL — — — 35 39 42 46 51 59 71 91 130 230 1200 NL NL NL DGTR/L 16B-3D35-JHP-SL — — — 75 90 113 155 250 650 NL NL NL NL NL NL NL NL DGTR/L 20B-3D40-JHP-SL 56 62 71 83 102 134 200 400 NL NL NL NL NL NL NL NL NL DGTR/L 25B-3D40-JHP-SL 50 55 60 67 75 85 100 115 140 200 350 1500 NL NL NL NL NL Depth T 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 NL - No Limit Example: For a 9 mm depth of groove on a 75 mm workpiece diameter, six tools may be used. Flow Rate vs. Pressure 70 Bar 100 Bar 140 Bar Designation Flow Rate (liters/min) Flow Rate (liters/min) Flow Rate (liters/min) DGTR/L ...2-JHP-SL 3-4 4-5 5-6 DGTR/L ...3-JHP-SL 5-6 6-7 7-8 Spare Parts Designation DGTR/L 12B-2D24-JHP-SL PIN-32121 SR M5-24145 SR 5/16UNF TL360 HW 2.5 SR M2.5X6 DIN913 HW 5/32" SR M2.5X2.5 DIN913 DGTR/L 16B-2D35-JHP-SL PIN-32121 SR M5-24145 SR 5/16UNF TL360 HW 2.5/5 SR M2.5X6 DIN913 HW 5/32" SR M2.5X2.5 DIN913 DGTR/L 20B-2D35-JHP-SL PIN-32121 SR M5-24145 PLG 1/8BSP TL360 HW 2.5/5 SR M2.5X6 DIN913 HW 5.0 SR M2.5X2.5 DIN913 DGTR/L 12B-3D24-JHP-SL PIN-32121 SR M5-24145 SR 5/16UNF TL360 HW 2.5 SR M2.5X6 DIN913 HW 5/32" SR M2.5X2.5 DIN913 DGTR/L 16B-3D35-JHP-SL PIN-32121 SR M5-24145 SR 5/16UNF TL360 HW 2.5/5 SR M2.5X6 DIN913 HW 5/32" SR M2.5X2.5 DIN913 DGTR/L 20B-3D40-JHP-SL PIN-32121 SR M5-24145 PLG 1/8BSP TL360 HW 2.5/5 SR M2.5X6 DIN913 HW 5.0 SR M2.5X2.5 DIN913 DGTR/L 25B-2D35-JHP-SL PIN-32121 SR M5-24145 PLG 1/8BSP TL360 HW 2.5/5 SR M2.5X6 DIN913 HW 5.0 SR M2.5X2.5 DIN913 DGTR/L 25B-3D40-JHP-SL PIN-32121 SR M5-24145 PLG 1/8BSP TL360 HW 2.5/5 SR M2.5X6 DIN913 HW 5.0 SR M2.5X2.5 DIN913 374 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017